Raw material treatment system for rotary hearth furnace, and process thereof

A raw material processing and rotary hearth furnace technology, which is applied in the rotary hearth furnace raw material processing system and its process field, can solve the problems of stable raw material system production and increased process energy consumption, so as to avoid unsmooth blanking, improve production stability, and save The effect of water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

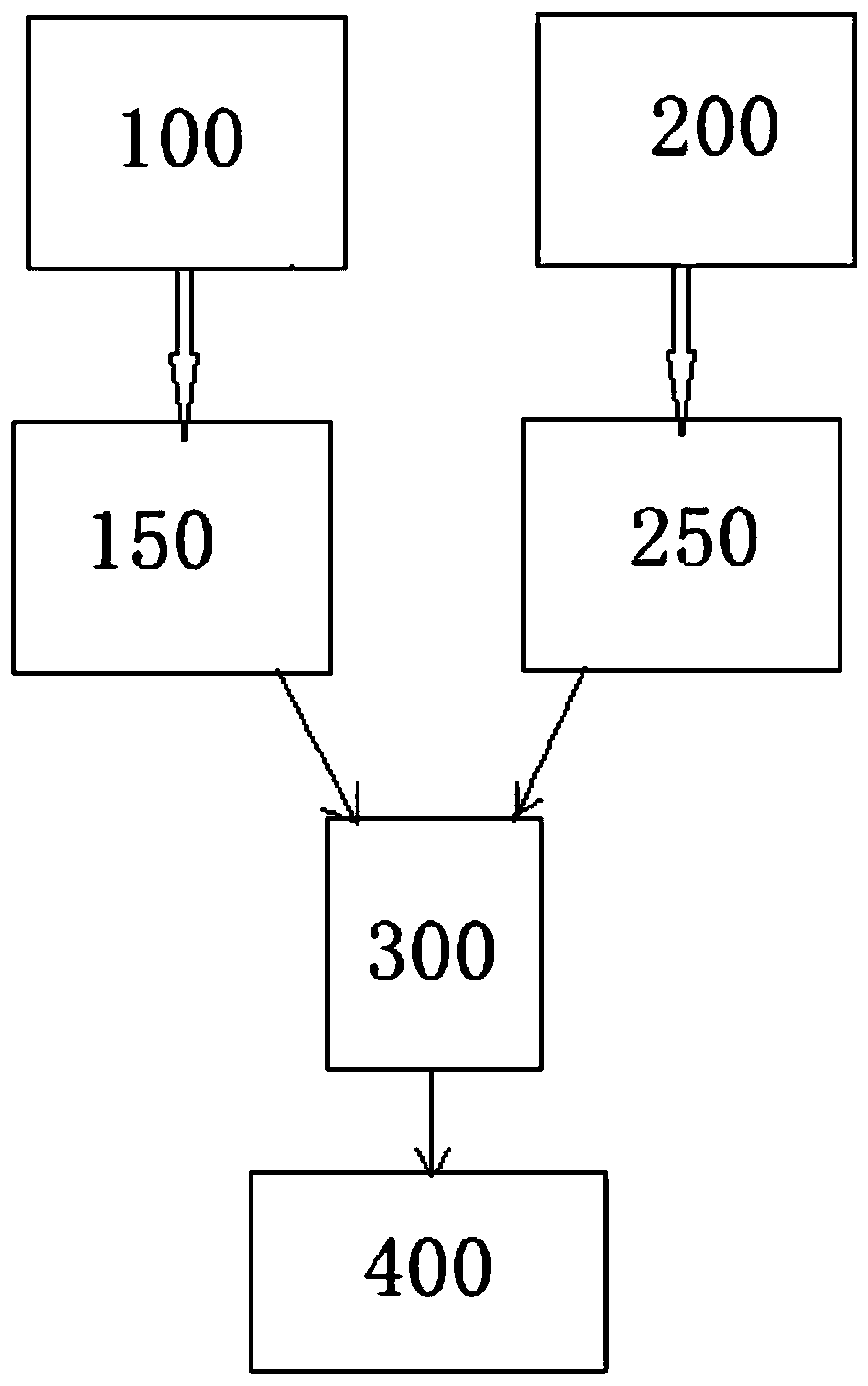

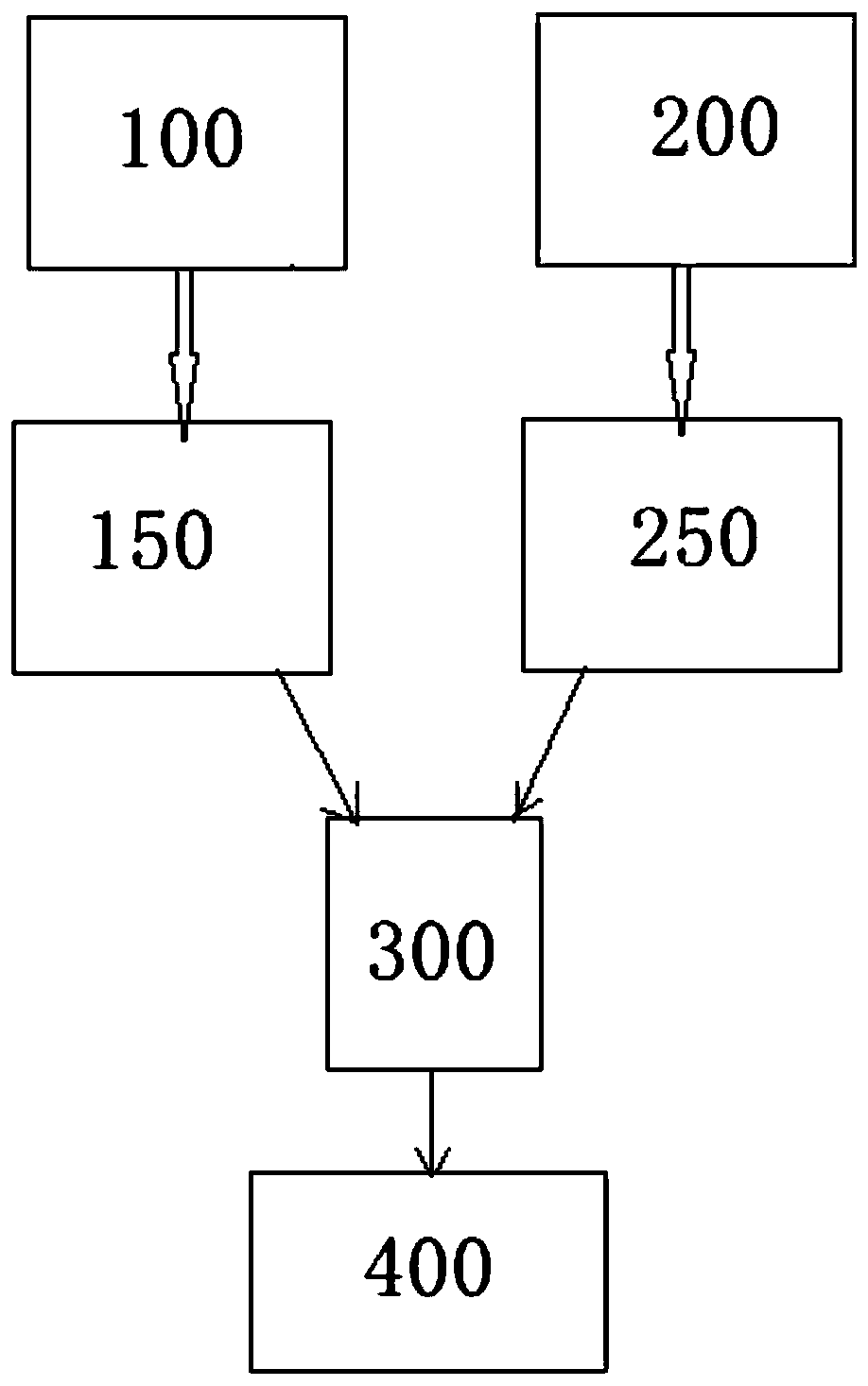

[0037] A kind of rotary hearth furnace raw material processing system of the present embodiment, such as figure 1 As shown, it includes the ash receiving device 100 and the sludge receiving device 200 in parallel with the process, and the mixing device 300 and the ball forming device 400 arranged in sequence in accordance with the process; the ash receiving device 100 and the sludge receiving device 200 After receiving the corresponding materials, they are sent to the mixing device 300 for mixing, and after mixing, they are transferred to the ball forming device 400 for ball forming processing.

[0038] In the raw material treatment system of the rotary hearth furnace of this embodiment, by feeding the ash receiving device 100 and the sludge receiving device 200 in parallel to the mixing device 300, the moisture content of the sludge in the sludge bin 15 is controlled at 20%-30%, and The sludge weight ratio in the mixing device 300 is 20%-50%, the sludge drying system of the p...

Embodiment 2

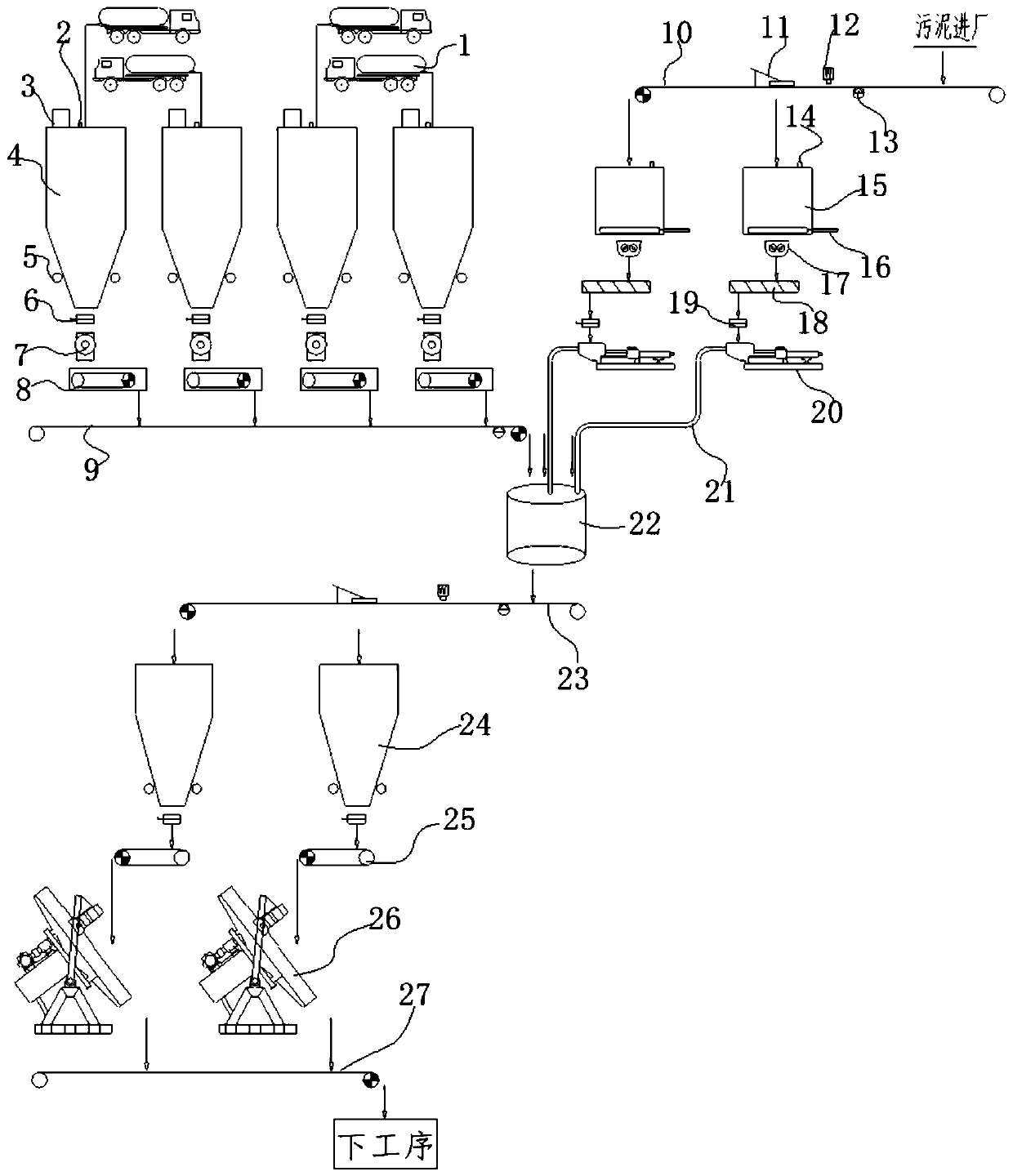

[0040] A kind of rotary hearth furnace raw material processing system of the present embodiment, the specific structure is basically the same as embodiment 1, and the improvements are as follows: figure 2 As shown, the ash receiving device 100, the sludge receiving device 200 and the mixing device 300 are respectively equipped with an ash batching device 150 and a sludge batching device 250; the ash receiving device 100 includes several vertical batching bins 4; The ashes batching device 150 includes a batching belt conveyor 9 arranged below the vertical batching bin 4; each of the vertical batching bins 4 stores different ash materials, and various ash materials are classified and temporarily stored as 4 in this embodiment. Each of the vertical batching bins 4 stores different ashes, and various ashes are classified and temporarily stored, such as zinc-containing dust removal ash and binder, and zinc-containing dust removal dust includes blast furnace dust removal dust, conve...

Embodiment 3

[0043] A raw material processing system for a rotary hearth furnace in this embodiment has the same basic structure as that in Embodiment 2, and the improvement is that a slide valve 6 and a star-shaped ash discharge valve 7 are provided at the bottom outlet of the vertical batching bin 4, facing A batching scale 8 is also arranged below the star-shaped ash unloading valve 7. After the batching scale 8 is batched, the material is dropped to the batching belt machine 9, so as to facilitate the feeding, weighing and conveying of the ash according to the ratio; the bottom of the sludge bin 15 The arch-breaking carriage 16 is provided to avoid problems such as unsmooth feeding and blockage of the sludge bin 15. A feeder 17 is installed below the bottom outlet of the sludge bin 15, and the feeder 17 discharges the material to the screw feeder scale 18. The screw feeding scale 18 communicates with the sludge conveying pump through pipelines, which is convenient for sludge feeding, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com