Method for industrially producing aphidius gifuensis ashmaed product

An aphid wasp, factory-like technology, applied in the field of biological control, can solve the problems of the aphid wasp being unable to become a bio-control product, easy to damage the aphid wasp, and the rigid aphid, etc., achieving a significant drying effect and a low damage rate. , excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053]Experiment site: Kunming Xundian Tobacco Technology Promotion Station

[0054] experimental method:

[0055] 1. Collect wild aphids and aphids to purify and preserve species to form seed aphids and seed bees;

[0056] 2. In the seedling shed, use floating seedlings to breed tobacco seedlings, sow seeds on a 40-hole floating seedling tray, and when the tobacco seedlings grow to five leaves and one center, tear the aphid leaves into small pieces, spread them on the tobacco seedlings, and then The amount of aphids is 10 heads / plant; cover them with 80-mesh insect-proof nets after the aphids are picked up;

[0057] 3. When the average amount of aphids on the tobacco seedlings on the floating seedling tray reaches 220, move the qualified tobacco seedlings into the bee receiving shed, and use the leaves with stiff aphid leaves to receive bees, according to the ratio of bees: aphids 1:20 Insert the seed bees; collect the tobacco leaves with stiff aphids 15-17 days after recei...

Embodiment 2

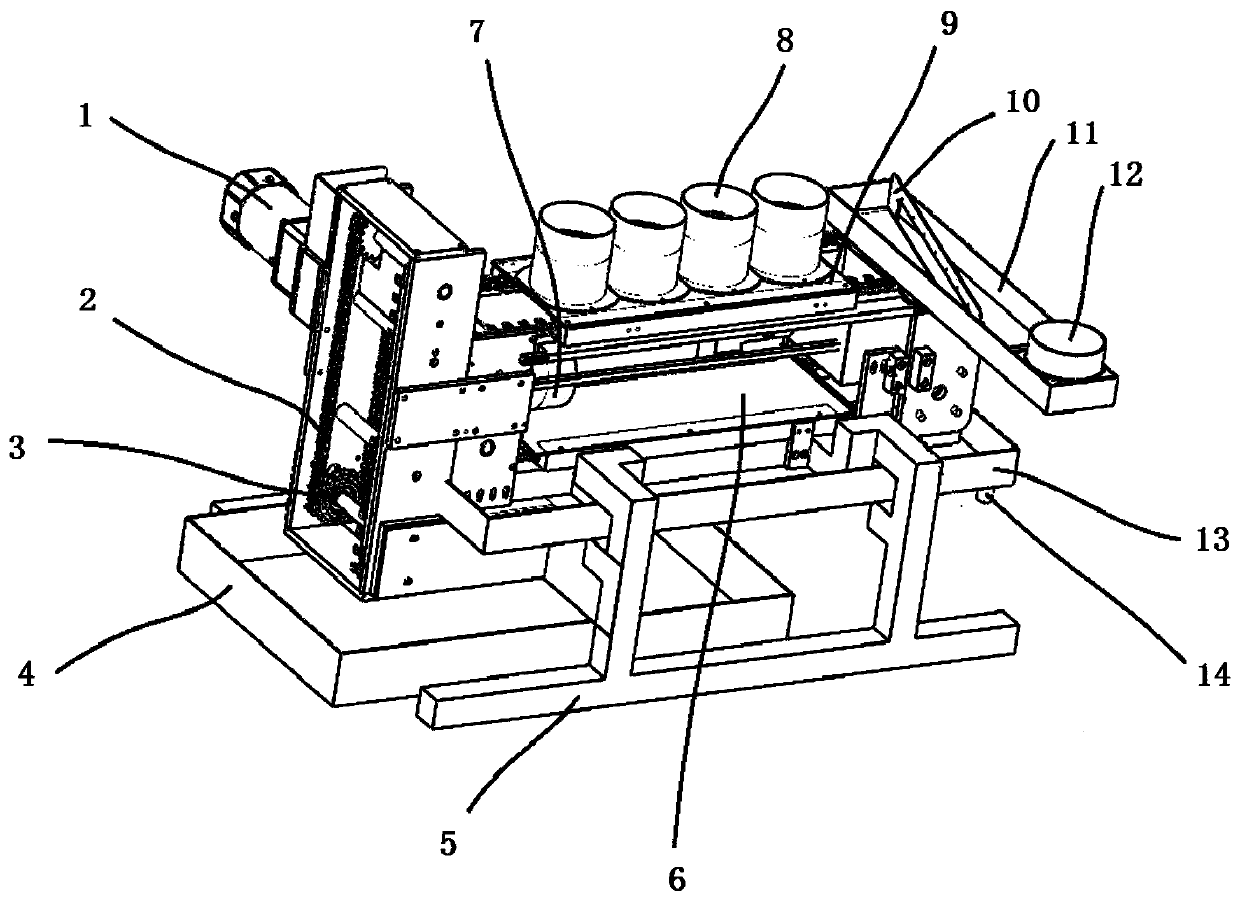

[0066] Such as Figure 2-3 As shown, the insect drying device includes: a filter assembly, a first air-drying assembly 18 and a second air-drying assembly 16 arranged in sequence.

[0067] Specifically, the horizontally arranged first air-drying assembly 18 includes four front air ducts 8 and a conveyor-type first air-drying network. 8 can blow through the first air-drying net; the ring structure of the first air-drying net is provided with a baffle 6, and during the drying process of the front air duct 8, the water droplets and impurities on the first air-drying net will fall on the baffle after being blown away. 6, the accumulated water on the baffle plate 6 can slide down from the edge of the baffle plate 6 into the sump 13, and the bottom of one end of the sump 13 is provided with a drainpipe 14 to prevent the water in the sump 13 from overflowing;

[0068] The vertically arranged second air-drying assembly 16 includes a rear air duct 7 and a conveyor belt-type second air...

Embodiment 3

[0080] Experiment site: Kunming Xundian Tobacco Technology Promotion Station

[0081] experimental method:

[0082] 1, adopt the homogeneous high-density multifarious honeybee mode of the present invention to obtain in embodiment 1 the stiff aphid leaf of Aphids persicae is harvested for subsequent use;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com