Switch cabinet valve mechanism

A technology of switch cabinets and valves, which is applied in the direction of pull-out switch cabinets, switch devices, and guard plates/protection devices of switch devices, etc., which can solve problems such as human safety hazards, static electricity problems in insulating parts, unsafety, etc., and achieve structural High intensity, easy and labor-saving activities, and a strong set of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further explained below in conjunction with the drawings:

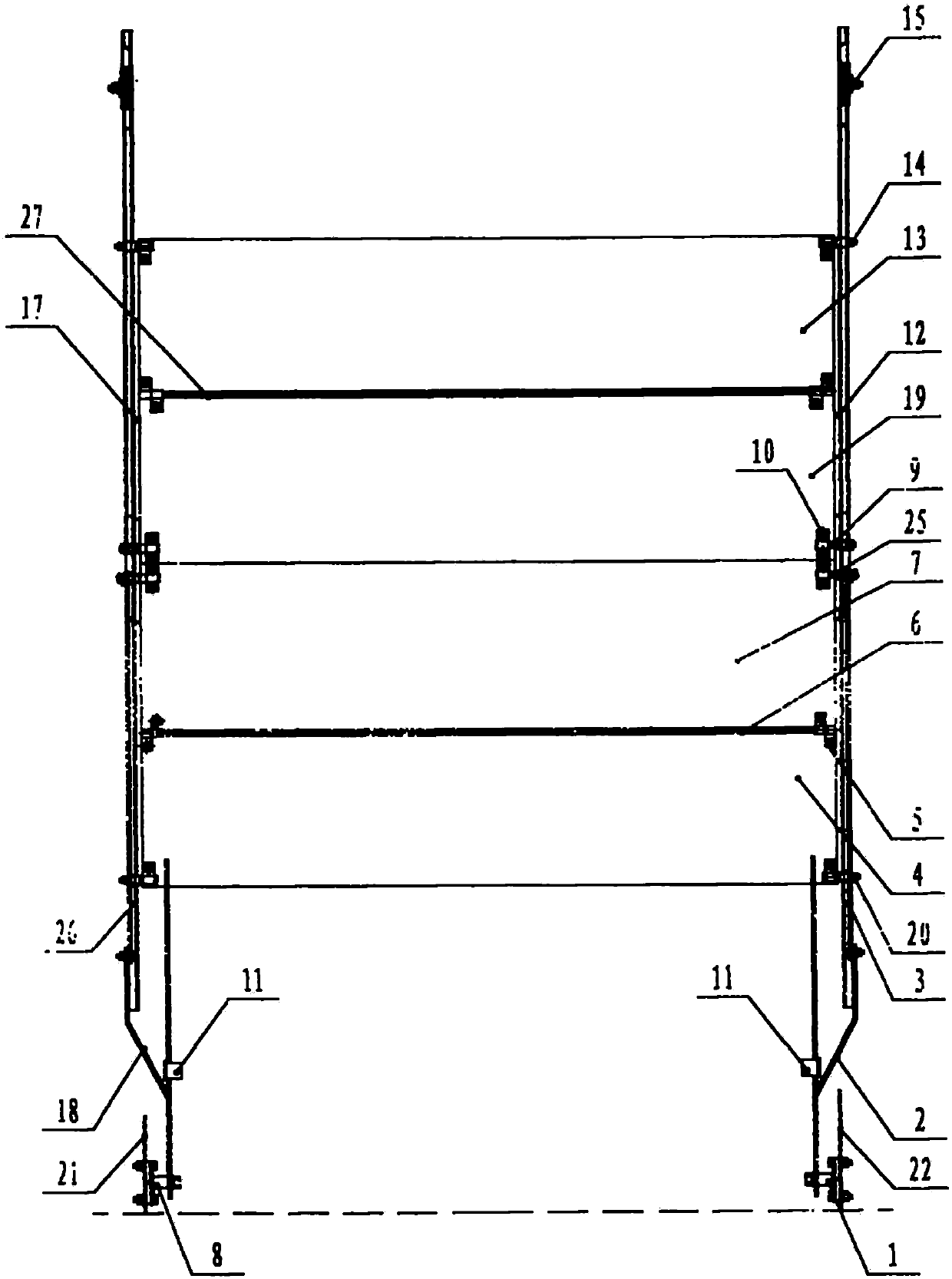

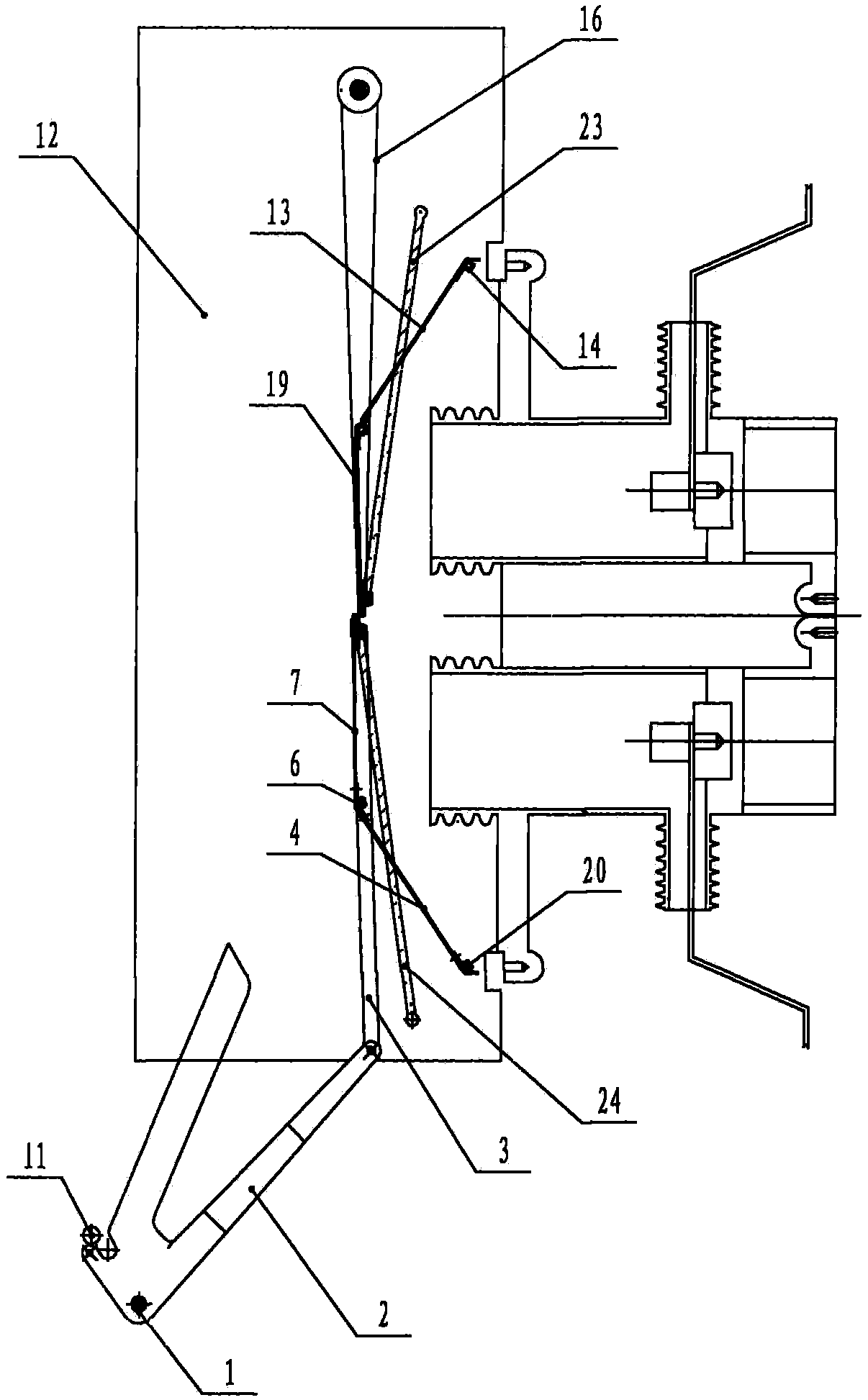

[0018] Such as figure 1 As shown, the chute plate I17 and the chute plate II12 are respectively fixed on the left side wall 21 and the right side wall 22 of the switch cabinet body, and the pulley I and the pulley II15 are respectively fixed on the chute plate I17 and the chute plate II12. At the top position, the fixed pin I8 and the fixed pin II1 are respectively fixed at the bottom of the left side wall 21 and the right side wall 22 of the switch cabinet. The bottoms of the Dalian rod I18 and the Dalian rod II2 are respectively sleeved on the fixed pin I8 And on the fixed pin II1, the valve plate I4, the valve plate II7, the valve plate III19 and the valve plate IV13 are arranged between the chute plate I17 and the chute plate II12 and are arranged in sequence from bottom to top, wherein the valve plate I4 and the valve plate II7 are composed The lower valve, the valve plate III19 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com