Fabricated building outer protective frame and fabricated building construction method

An external protection and assembly technology, applied in the field of scaffolding, can solve the problems of complex frame structure and operation, imperfect design performance, too large reserved holes in the wall, etc., to achieve simple and reliable connection, eliminate safety hazards, and facilitate The effect of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

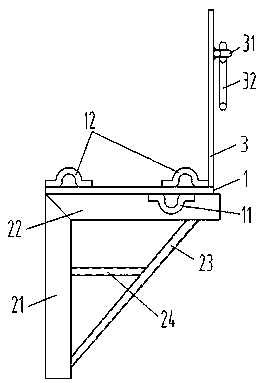

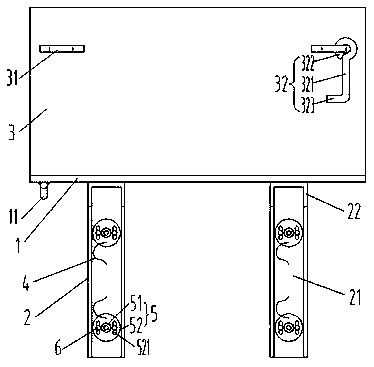

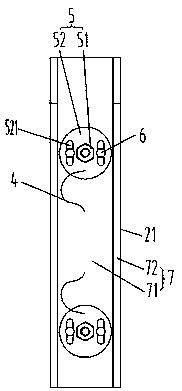

[0047] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0048] see Figure 1-5, the prefabricated building exterior protective frame of specific embodiment, comprises horizontal pedal 1, and the lower surface of described pedal 1 is connected with two tripods 2 for connecting the wall, and two tripods 2 are spaced apart along the length direction of pedal 1 Setting, the upper surface of the pedal 1 is connected with a vertical front guard plate 3; the tripod 2 includes a vertical shelf 21 and a horizontal shelf 22 connected in an inverted L shape, and the horizontal shelf 22 is connected to the pedal 1 is connected to the lower surface and is perpendicular to the length direction of the pedal 1. The vertical shelf 21 is flush with the wall side of the pedal 1 so as to be connected to the wall. The front guard plate 3 is connected to the wall side of the pedal 1. The opposite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com