Efficient wet-process phosphoric acid graphite heat exchanger scale inhibitor, preparation method and application

A technology of graphite heat exchanger and wet-process phosphoric acid, applied in chemical instruments and methods, phosphorus oxyacid, condensed phosphoric acid, etc., can solve the problems of a large number of air bubbles in the scale inhibitor, increased power consumption of concentrated steam, and difficulty in production, etc. Achieve the effect of prolonging the start-up period, improving the heat exchange efficiency and reducing the corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

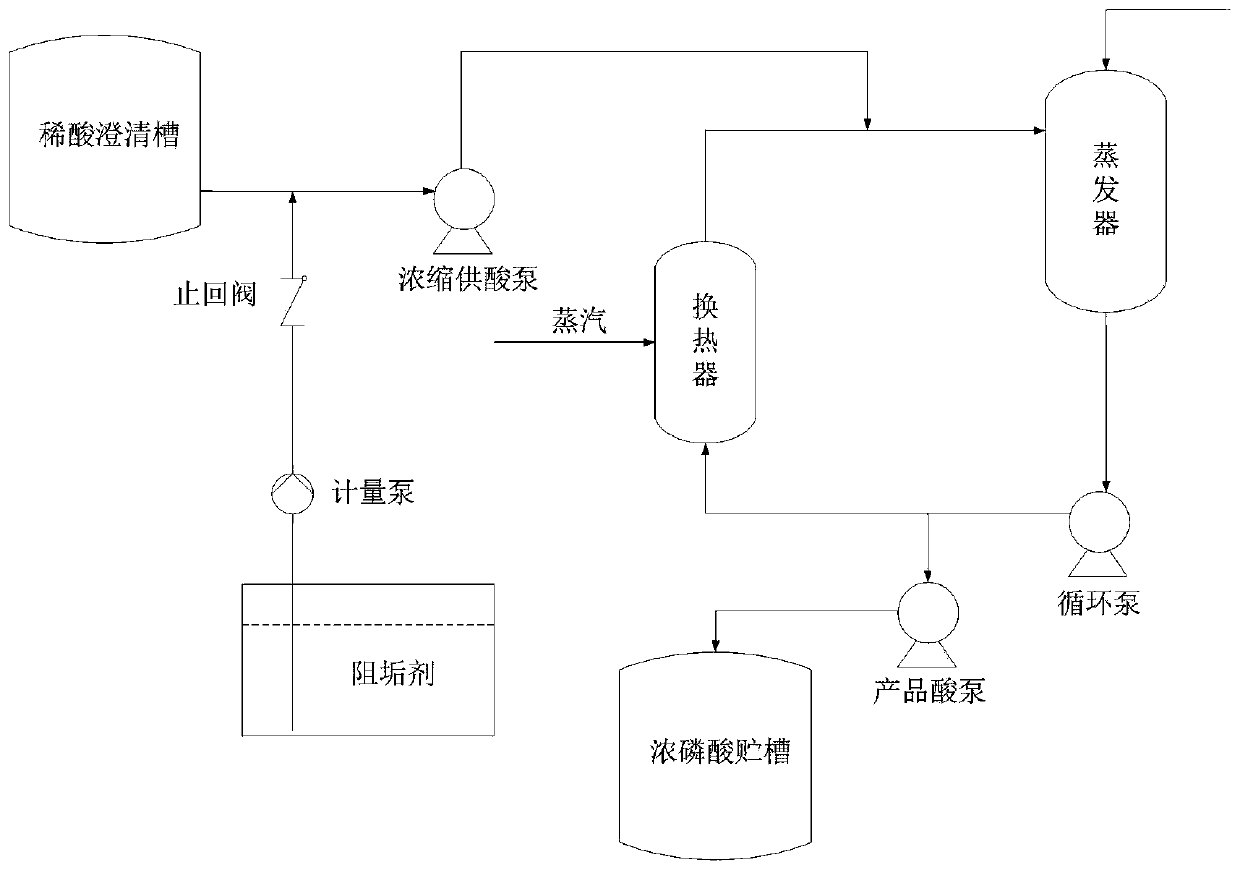

[0019] in such as figure 2 The shown wet-process phosphoric acid concentration graphite tube evaporation system structure is used for production experiments. According to the flow rate of the acid feed pump for wet-process phosphoric acid concentration, scale inhibitors are dosed at a rate of 30ppm. The antiscalant components are lauryl polyoxypropylene ether sulfonate, succinic acid and isoprene glycol, all of which are of industrial grade, and the parts by mass are 31 parts, 29 parts and 40 parts respectively. The scale inhibitor is mixed with dilute phosphoric acid through the dilute acid pump and then enters the concentrated evaporation system. During the process of heat exchange and concentration between the steam and phosphoric acid, the chelation solubilization, lattice distortion and dispersion of the scale inhibitor prevent and Delay the fouling of graphite tubes in the process of wet phosphoric acid concentration, strip and clean the original scale of graphite tubes...

Embodiment 2

[0025] in such as figure 2 The shown wet-process phosphoric acid concentration graphite tube evaporation system structure is used for production experiments. According to the flow rate of the acid feed pump for wet-process phosphoric acid concentration, scale inhibitors are dosed at a rate of 35ppm. The antiscalant components are lauryl polyoxypropylene ether sulfonate, succinic acid and isopropanol, all of which are of industrial grade, and the parts by mass are 34, 29 and 37 parts respectively. The scale inhibitor is mixed with dilute phosphoric acid through the dilute acid pump and then enters the concentrated evaporation system. During the process of heat exchange and concentration between the steam and phosphoric acid, the chelation solubilization, lattice distortion and dispersion of the scale inhibitor prevent and Delay the fouling of graphite tubes in the process of wet phosphoric acid concentration, strip and clean the original scale of graphite tubes, and reduce the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com