Breaking and recovering device for ceramic manufacturing waste

A recovery device and waste material technology, which is applied in the field of ceramic waste crushing and recovery devices, can solve the problems of incomplete crushing, waste, and reduced service life of pressure rollers, and achieve the effects of preventing displacement, safe and convenient use, and convenient post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

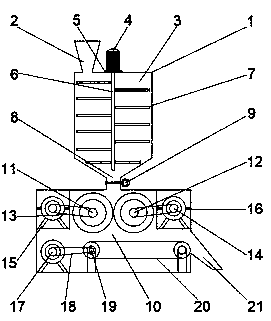

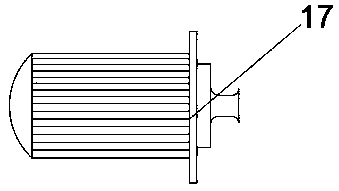

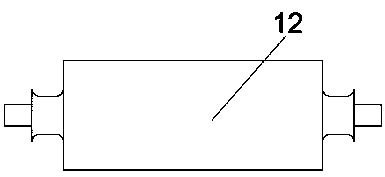

[0017] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, a crushing and recycling device for ceramic manufacturing waste, including a device body 1, a feed port 2, a crushing chamber 3, a crushing motor 4, fixing screws 5, a crushing rod 6, and a crushing frame 7 , the first discharge port 8, the baffle plate 9, the secondary crushing chamber 10, the first pressure roller 11, the second pressure roller 12, the first transmission belt 13, the motor 14, the motor bracket 15, the limit spring 16, the transmission Motor 17, second transmission belt 18, transmission wheel 19, transmission belt 20 and second discharge port 21, device body 1 top is provided with feed port 2, and below feed port 2 is provided with crushing chamber 3, and feed port 2. A crushing motor 4 is arranged on one side, and fixing screws 5 are arranged on both sides of one end of the crushing motor 4. A crushing rod 6 is arranged on one end of the crushing motor 4. A cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com