Environment-friendly simple electronic cigarette atomizer

An electronic cigarette atomizer and a simple technology, applied in the field of electronic cigarettes, can solve the problems of easy carbonization of the cotton layer on the surface of the heating net, reducing the user experience, affecting the effect, etc., so as to reduce manpower, improve user experience, and avoid pollution and waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

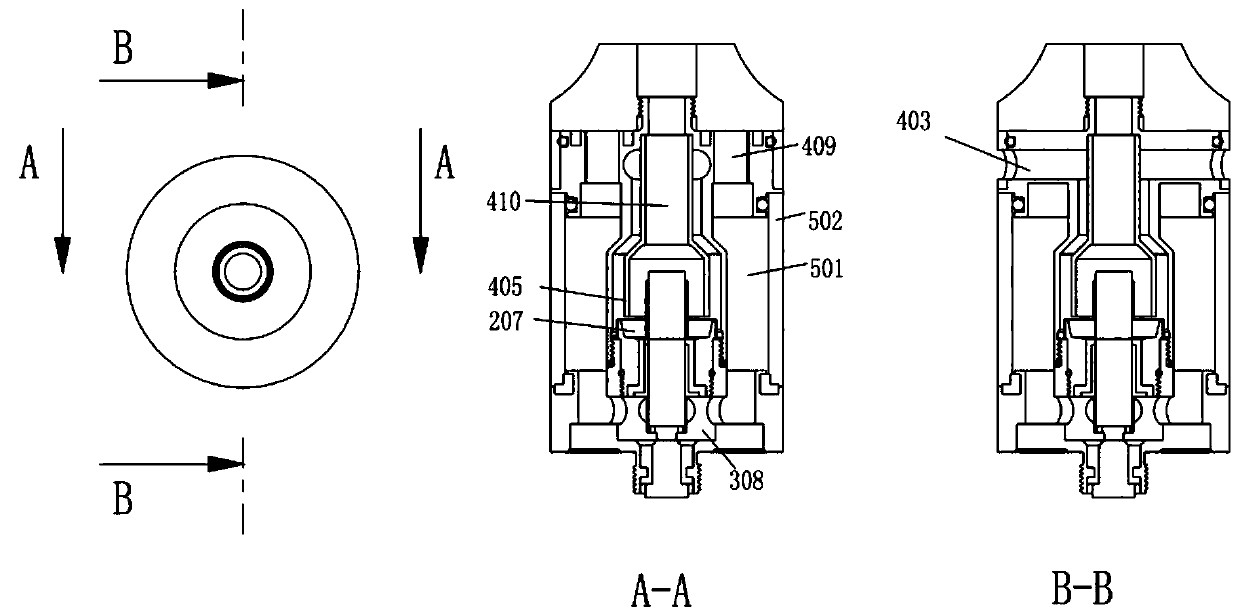

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

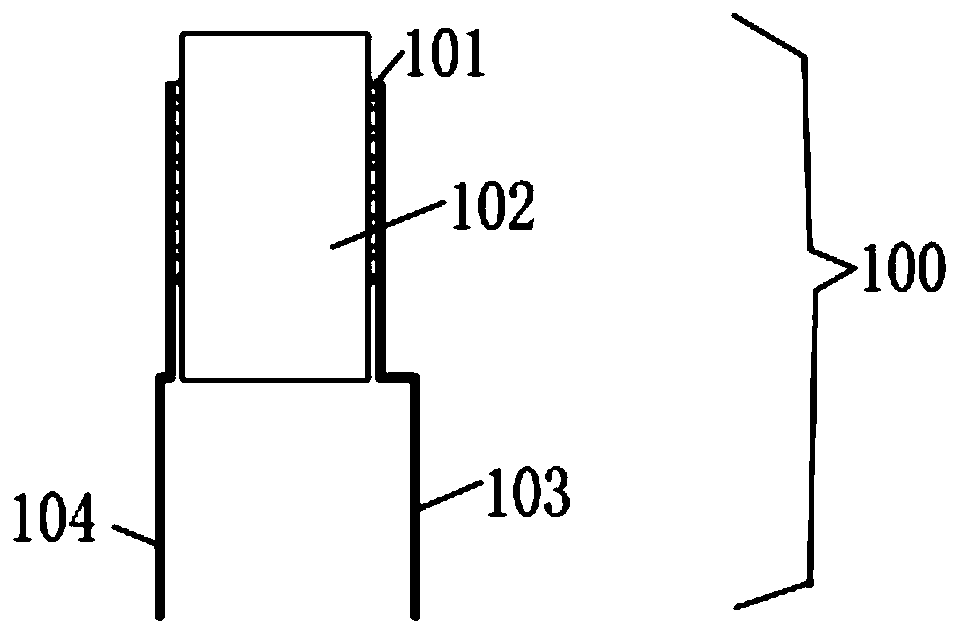

[0027] Combined with the accompanying drawings, from figure 1 It can be seen that the atomizer includes a heating element 100 and an atomizing core assembly 200 located in the electronic cigarette atomizer for heating and atomizing liquid; the atomizing core assembly 200 is screwed into the atomizing seat assembly 300 The middle cavity of the atomizing core assembly 200 is provided with a lower oil-absorbing core 205, and the lower end opening communicates with the oil inlet cavity 308 in the middle of the atomizing seat assembly 300; Tighten it to form oil storage bin 501, air intake channel 403, and air outlet channel 410; the lower edge of the partition cover 405 is arranged below the heating net 101, and the top air intake channel is changed to the lower air intake.

[0028] combine figure 1 , see figure 2 , image 3 , in an embodiment, the heating n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com