Tea and prinsepia utilis royle leaf composition, preparation method and application thereof

A green thorn fruit leaf and composition technology, applied in the field of tea derivative products, can solve the problems of single taste and poor taste of tea smoke, and achieve the effect of improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment is a specific embodiment for preparing the composition product 1.

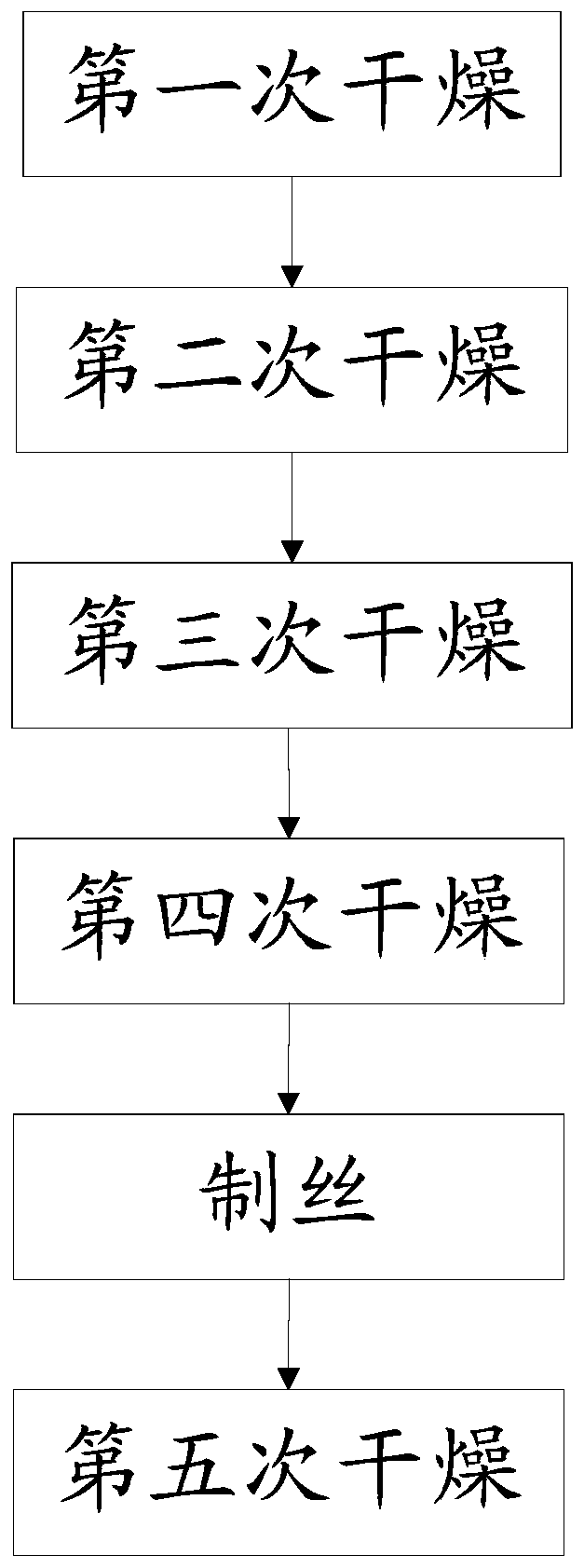

[0033] 90Kg of freshly picked tea leaves were removed and dried at 80°C for 60 minutes until the water content decreased by 30%, to obtain the first product 1.

[0034] The first product 1 was dried at 90° C. for 65 minutes until the water content was reduced by 20%, to obtain the second product 1 .

[0035] The second product 1 was dried at 80° C. for 50 minutes until the water content was reduced by 10%, then allowed to stand at room temperature, crushed and passed through a 200-300 mesh sieve to obtain the third product 1 .

[0036] After chopping 1Kg of green thorn fruit leaves, vacuum freeze-drying at -25°C for 60 minutes, the resulting frozen product was crushed and passed through a 200-300 mesh sieve to obtain the fourth product 1.

[0037] The third product 1 is mixed with the fourth product 1 to make silk to obtain the fifth product 1; wherein, the width of the fifth product 1 ...

Embodiment 2

[0040] This embodiment is a specific embodiment for preparing the composition product 2.

[0041] 100Kg of freshly picked tea leaves were removed and dried at 75°C for 45 minutes until the water content decreased by 30%, to obtain the first product 2.

[0042] The first product 2 was dried at 70° C. for 70 minutes until the water content was reduced by 20%, to obtain the second product 2 .

[0043] The second product 2 was dried at 90° C. for 80 minutes until the water content was reduced by 20%, then allowed to stand at room temperature, crushed and passed through a 200-300 mesh sieve to obtain the third product 2 .

[0044] After chopping 20Kg of green thorn fruit leaves, vacuum freeze-drying at -30°C for 30 minutes, the resulting frozen product was crushed and passed through a 200-300 mesh sieve to obtain the fourth product 2.

[0045] The third product 2 is mixed with the fourth product 2 to make silk to obtain the fifth product 2; wherein, the width of the fifth product ...

Embodiment 3

[0048] This embodiment is a specific embodiment for preparing the composition product 3.

[0049] 70Kg of freshly picked tea leaves were removed and dried at 60°C for 30 minutes until the water content decreased by 30%, to obtain the first product 3.

[0050] The first product 3 was dried at 75° C. for 40 minutes until the water content was reduced by 20%, to obtain the second product 3 .

[0051] The second product 3 was dried at 100° C. for 60 minutes until the water content was reduced by 30%, then allowed to stand at room temperature, crushed and passed through a 200-300 mesh sieve to obtain the third product 3 .

[0052] After chopping 30Kg of green thorn fruit, vacuum freeze-drying at -20°C for 55 minutes, the resulting frozen product was crushed and passed through a 200-300 mesh sieve to obtain the fourth product 3.

[0053] The third product 3 is mixed with the fourth product 3 to make silk to obtain the fifth product 3; wherein, the width of the fifth product 3 is 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com