Tea and momordica grosvenori composition, preparation method and application thereof

A composition and the technology of Luo Han Guo, applied in the fields of application, tea extraction, food science, etc., can solve the problems of single taste and poor taste of tea smoke, achieve the effect of improving taste, neutralizing bitterness, and improving user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

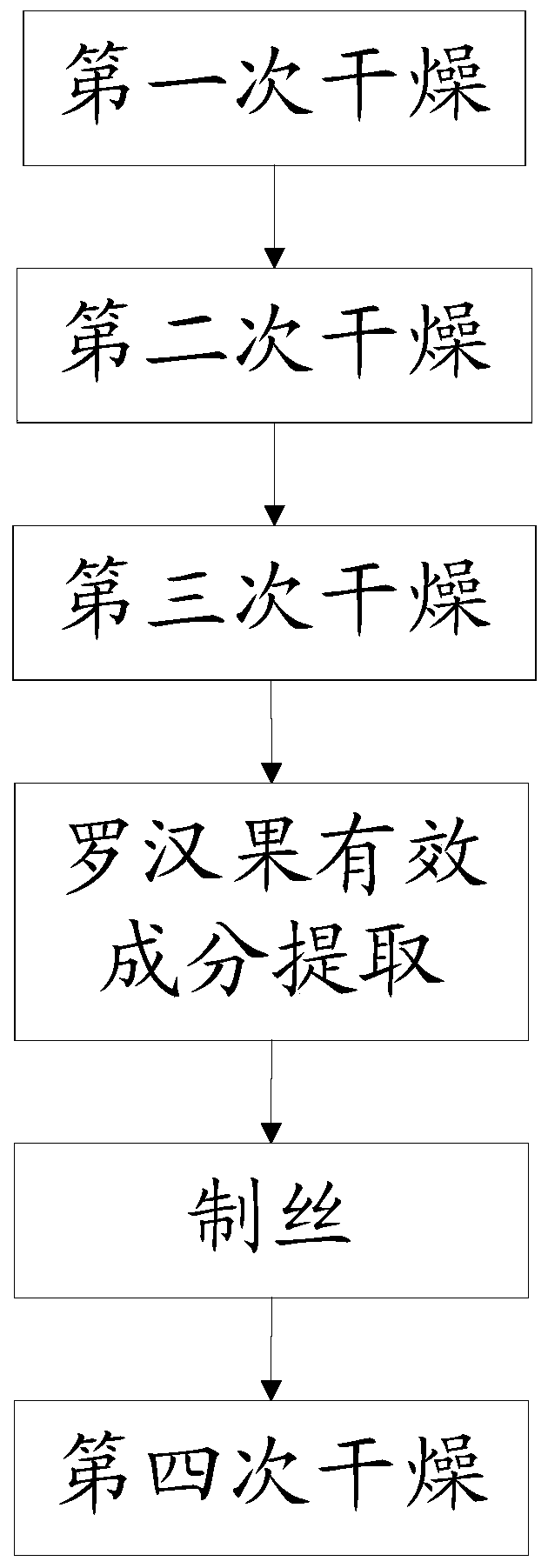

Method used

Image

Examples

Embodiment 1

[0034] This embodiment is a specific embodiment for preparing the composition product 1.

[0035] 90Kg of freshly picked tea leaves were removed and dried at 80°C for 60 minutes until the water content decreased by 30%, to obtain the first product 1.

[0036] The first product 1 was dried at 90° C. for 65 minutes until the water content was reduced by 20%, to obtain the second product 1 .

[0037] The second product 1 was dried at 80° C. for 50 minutes until the water content was reduced by 10%, then allowed to stand at room temperature, crushed and passed through a 200-300 mesh sieve to obtain the third product 1 .

[0038] 1Kg Luo Han Guo was treated with 0.5% pectinase solution, extracted with water at 126°C for 25 minutes, then continued with alcohol extraction at 110°C for 120 minutes, combined water extract and alcohol extract; concentrated the combined extract at 130°C After 25 minutes, the obtained concentrated solution was vacuum freeze-dried at -25°C for 60 minutes,...

Embodiment 2

[0042] This embodiment is a specific embodiment for preparing the composition product 2.

[0043] 100Kg of freshly picked tea leaves were removed and dried at 75°C for 45 minutes until the water content decreased by 30%, to obtain the first product 2.

[0044] The first product 2 was dried at 70° C. for 70 minutes until the water content was reduced by 20%, to obtain the second product 2 .

[0045] The second product 2 was dried at 90° C. for 80 minutes until the water content was reduced by 20%, then allowed to stand at room temperature, crushed and passed through a 200-300 mesh sieve to obtain the third product 2 .

[0046] 30Kg Luo Han Guo was treated with 0.5% pectinase solution, extracted with water at 120°C for 30 minutes, then continued with alcohol extraction at 100°C for 150 minutes, combined water extract and alcohol extract; concentrated the combined extract at 120°C After 20 minutes, the obtained concentrated solution was vacuum freeze-dried at -30°C for 30 minute...

Embodiment 3

[0050] This embodiment is a specific embodiment for preparing the composition product 3.

[0051] 70Kg of freshly picked tea leaves were removed and dried at 60°C for 30 minutes until the water content decreased by 30%, to obtain the first product 3.

[0052] The first product 3 was dried at 75° C. for 40 minutes until the water content was reduced by 20%, to obtain the second product 3 .

[0053] The second product 3 was dried at 100° C. for 60 minutes until the water content was reduced by 30%, then allowed to stand at room temperature, crushed and passed through a 200-300 mesh sieve to obtain the third product 3 .

[0054]15Kg Luo Han Guo was treated with 0.5% pectinase solution, extracted with water at 130°C for 22 minutes, then continued with alcohol extraction at 120°C for 130 minutes, combined water extract and alcohol extract; concentrated the combined extract at 125°C After 30 minutes, the obtained concentrated solution was vacuum freeze-dried at -20°C for 55 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com