An equipment health state assessment and prediction method based on industrial big data

A health status and prediction method technology, applied in data processing applications, electrical digital data processing, digital data information retrieval, etc., to achieve the effect of scientific health status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

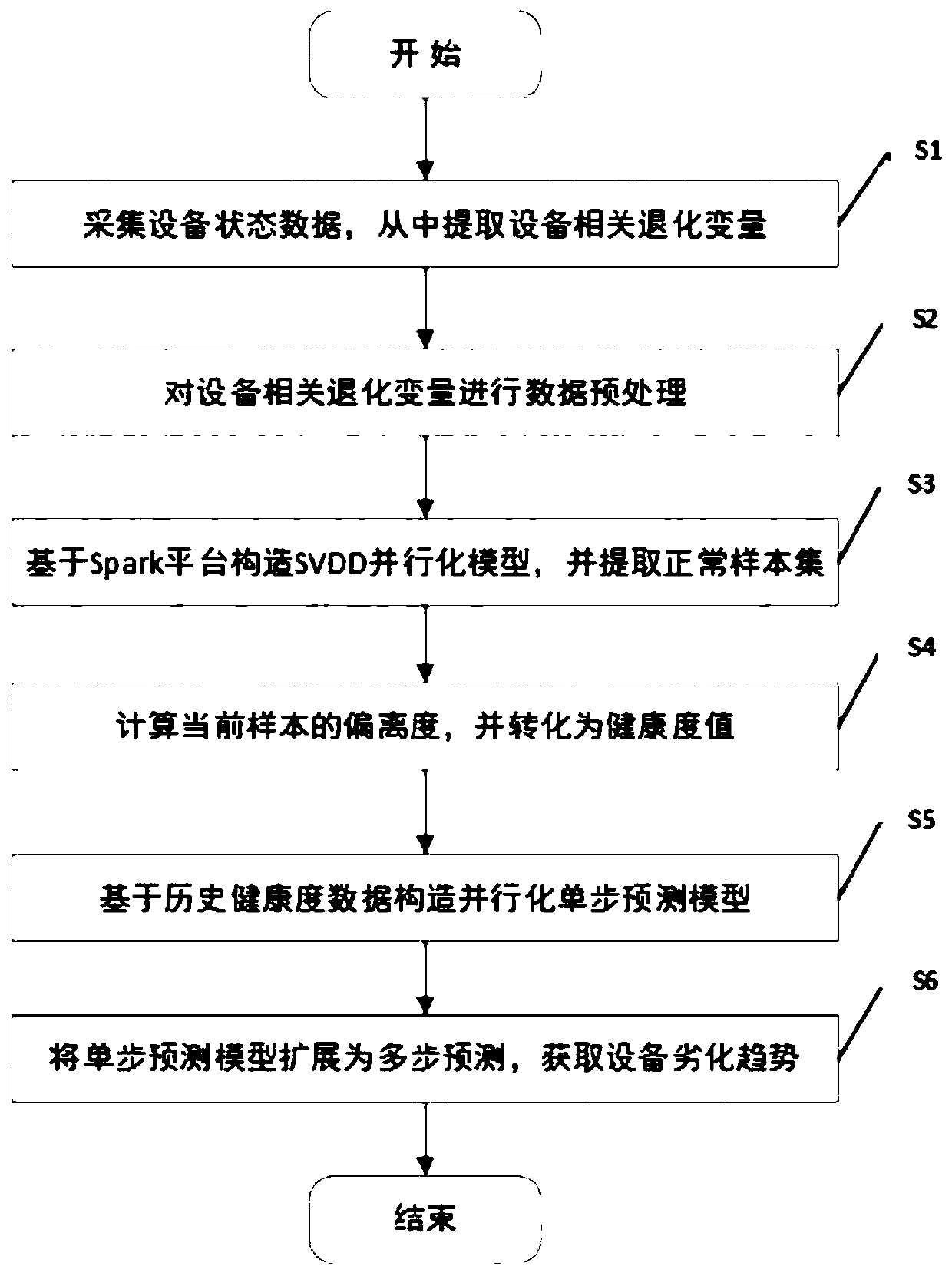

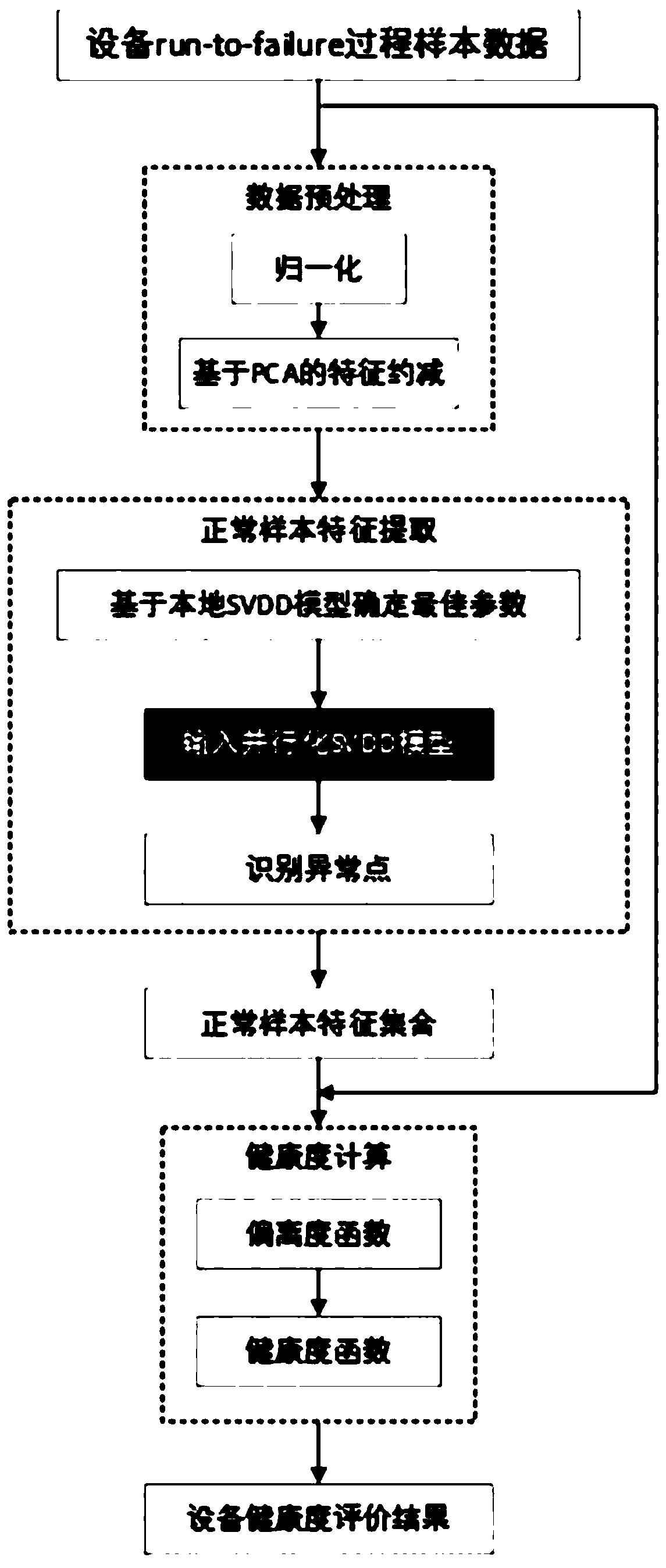

[0061] A method for evaluating and predicting equipment health status based on industrial big data described in this example, its calculation process is as follows figure 1 and image 3 , mainly including the following parts:

[0062] S1. First select several sets of relatively complete run-to-failure life cycle data from the equipment status data set, and select characteristic parameters that can represent the degradation state of the equipment and can be continuously monitored and recorded as the degradation variables of the equipment. Different types of industrial equipment can choose their own parameters to be monitored, mainly including speed, flow rate, pressure, temperature, power, current, etc.

[0063] S2. Perform effective data preprocessing for data-related degenerate variables, including normalization and feature reduction based on principal component analysis, and eliminate redundant variables in sample data;

[0064] Among them, the normalization adopts the max...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com