Laser tracker positioning method based on laser tracker multi-position measuring system

A laser tracker, measurement system technology, applied in radio wave measurement systems, measurement devices, instruments, etc., can solve the problem of inability to correct random components of measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

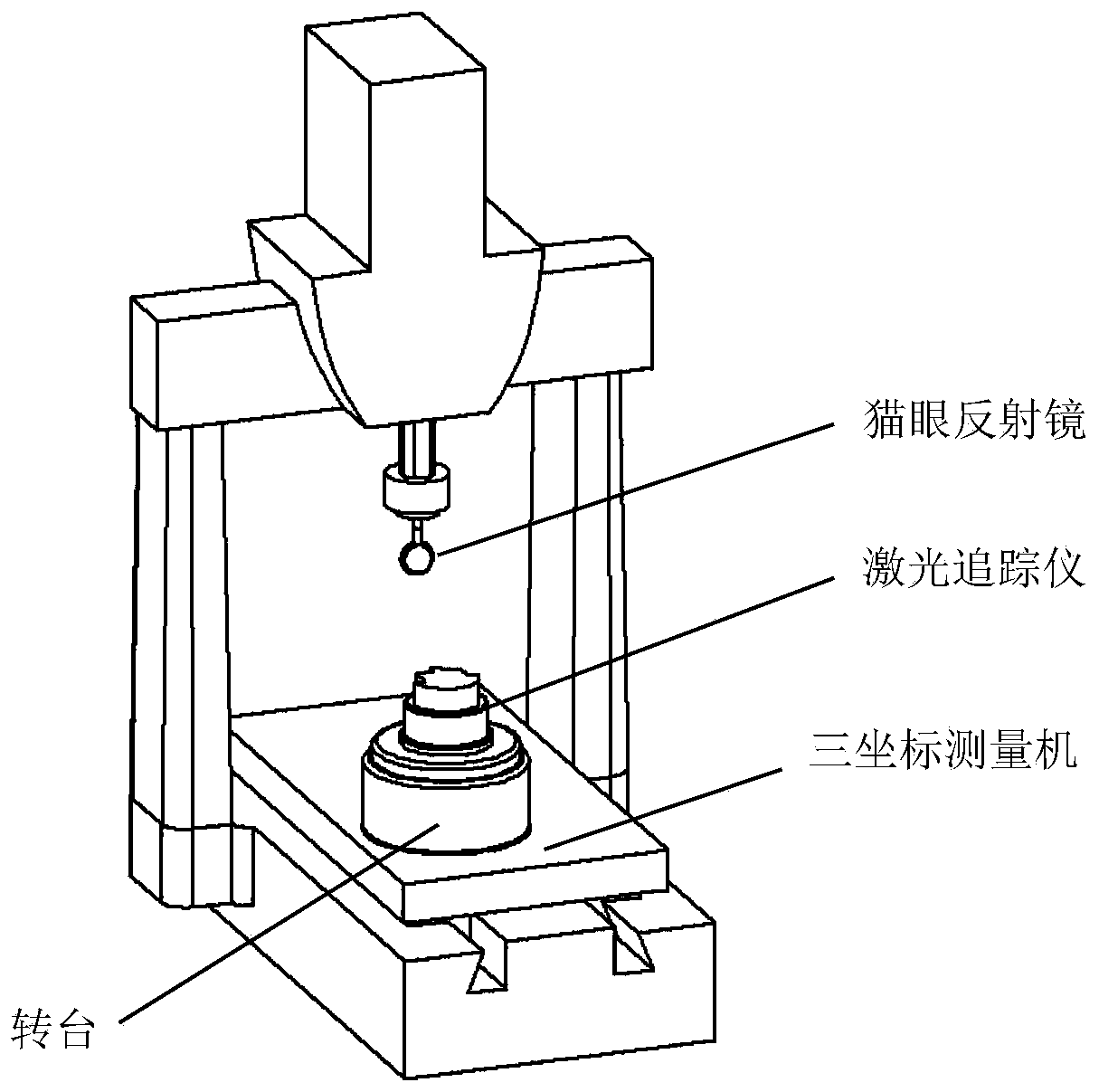

[0059] build as figure 1 The experimental platform of the multi-site measurement system of the laser tracker shown in the figure optimizes the site coordinates of the laser tracker through the following steps:

[0060] Step 1: Build a laser tracker multi-station measurement system. In the measurement system, the three-coordinate measuring machine is Leitz Infinity of Hexagon Company, the model of high-precision turntable is RT400, and the laser tracker is LaserTracer of Etalon Company, model 07 2009 TR IF. The spatial range of the points to be measured by the coordinate measuring machine is planned to be 450×600×450mm 3 . Within this space, the number of points to be measured is planned to be n=64, and the number of laser tracker stations is m=11. In the path planning of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com