Rear cover of hydraulic motor shell

A technology for hydraulic motors and shells, applied in the field of hydraulic motors, can solve the problems of increasing production cost and processing difficulty, shell side wall thickness, affecting quality, etc., and achieves the advantages of light overall weight, convenient machining, and low processing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

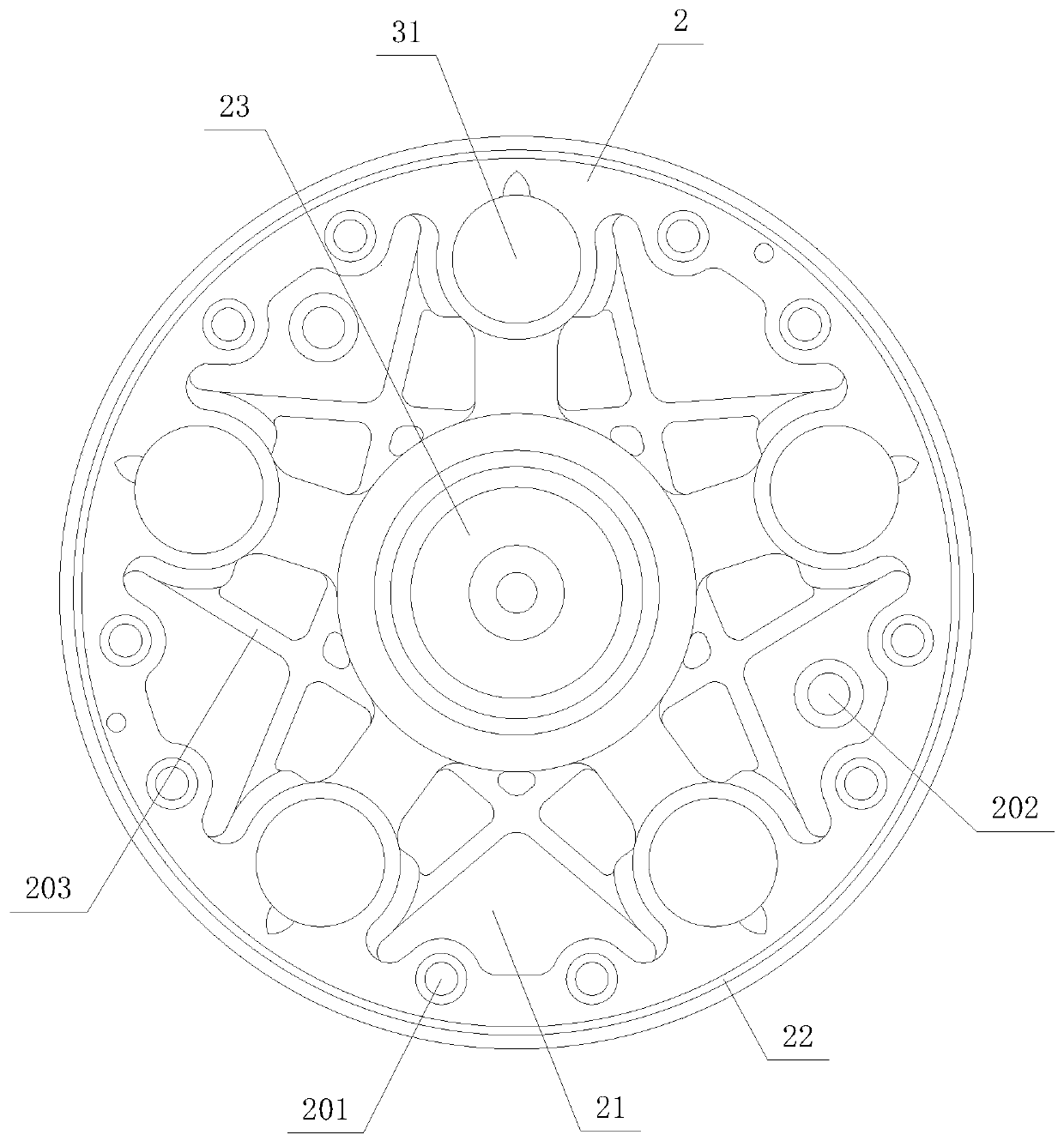

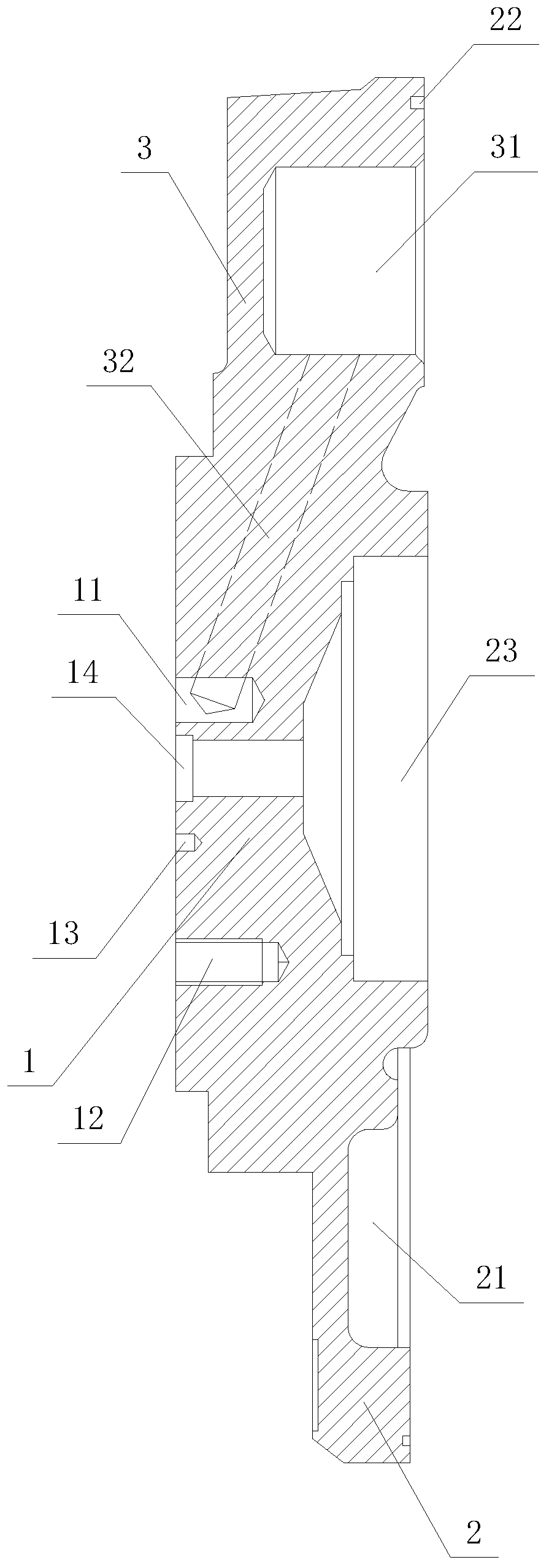

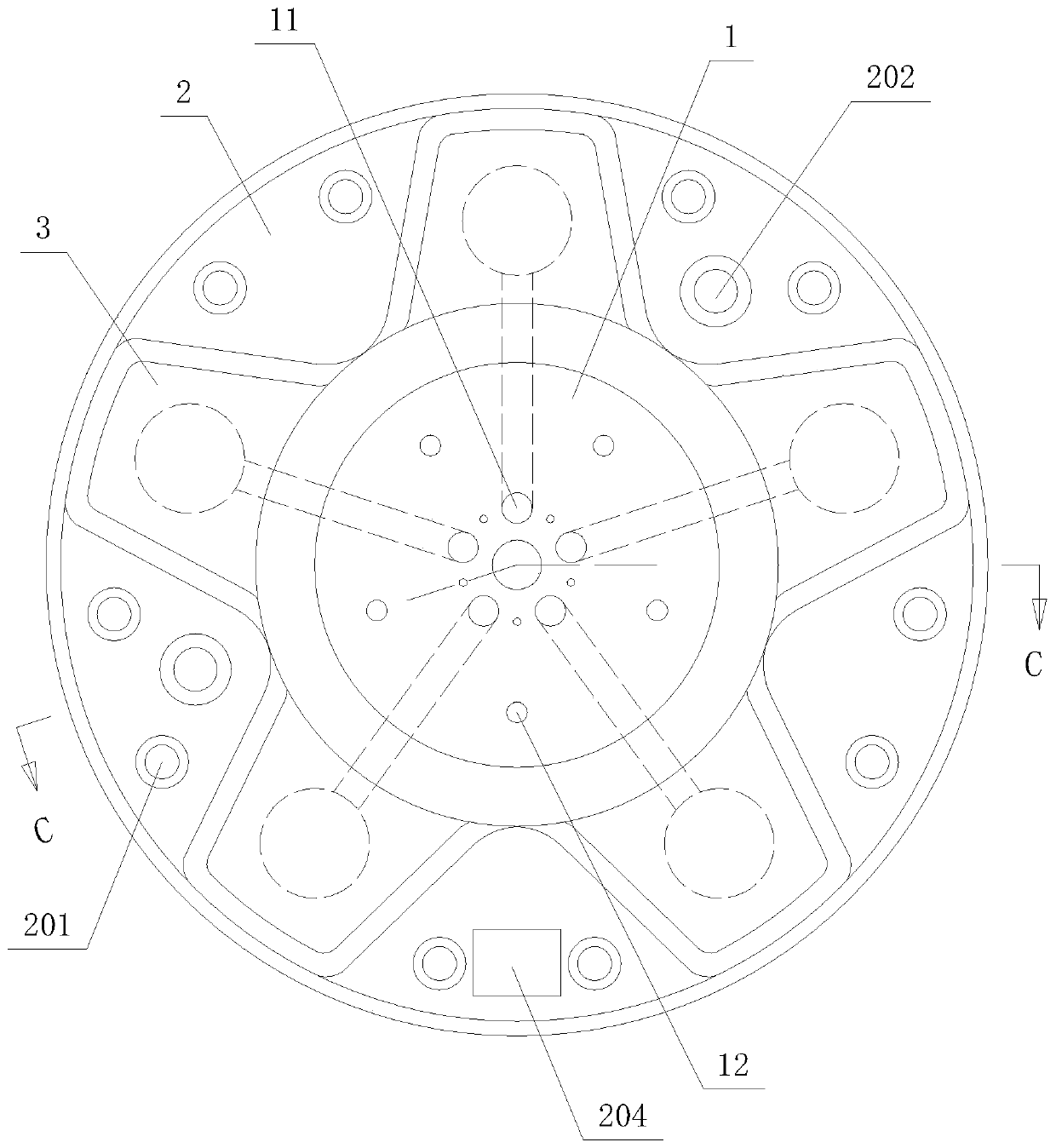

[0021] refer to Figure 1 to Figure 4 , the present invention provides a hydraulic motor housing back cover, comprising a cylindrical back cover body 1, the side wall of the back cover body extends radially outward to form a cover body 2, the front end surface of the cover body and the front end surface of the back cover body The distance between them is greater than 3 and less than 5mm. The cover body and the back cover body form a coaxial cylindrical structure. A central hole 14 is opened in the center of the rear end face of the back cover body. The center hole is in the form of a stepped hole. Specifically, it consists of It includes a first hole body and a second hole body before and after, wherein the diameter of the first hole body is greater than the diameter of the second hole body, and the depth of the first hole body is smaller than the dept...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com