Antibacterial flame retardant modified glass glue and preparation method thereof

A glass glue and modification technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of affecting the bonding performance, easy to condense, and need to be sealed for storage, etc., to improve the antibacterial ability, The effect of uniform flame retardancy and high antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

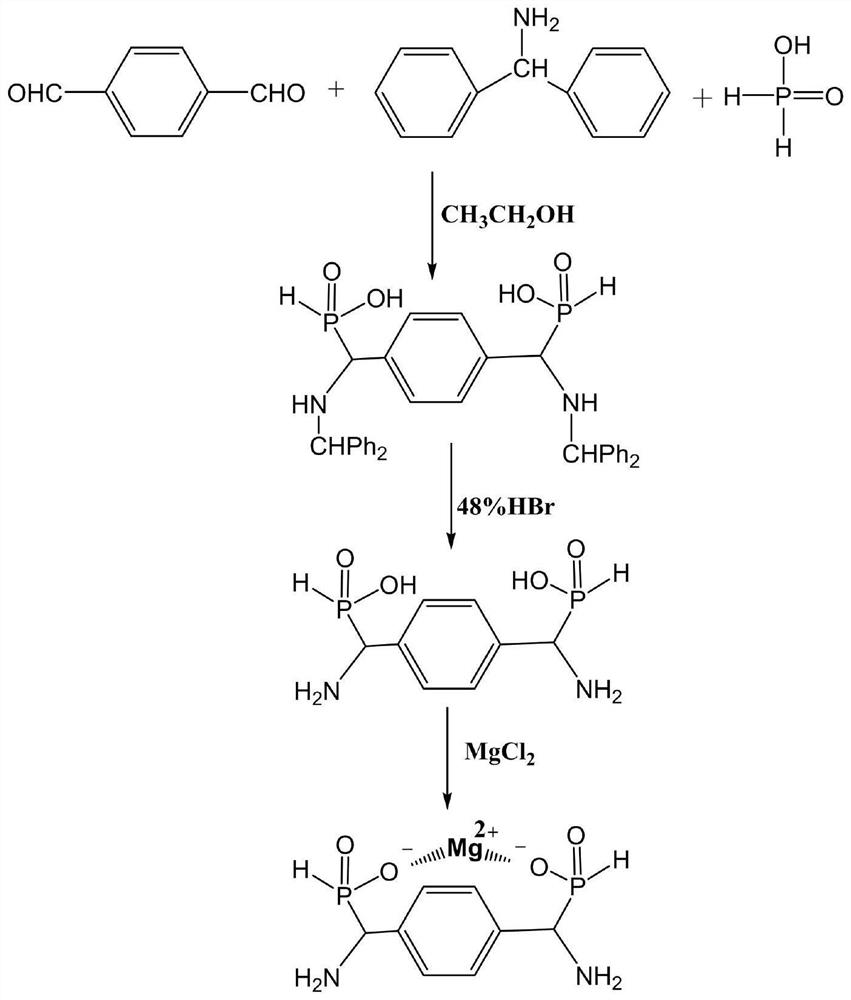

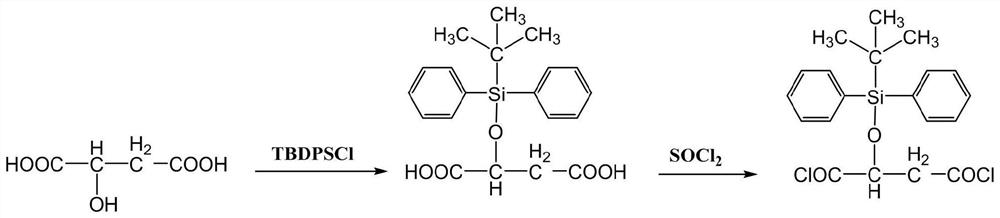

[0033] The preparation of diamino flame retardant monomer, the specific preparation process is as follows:

[0034] Step 1: Add 150g of 4-carboxybenzaldehyde and 500g of absolute ethanol into the reaction kettle, raise the temperature to 90°C and then add 197g of diphenylmethylamine and 79.2g of hypophosphorous acid to it, react at constant temperature for 12-14h, and then prepare the product Concentrate, the residue is washed with saturated brine, and then extracted with ethyl acetate, the obtained organic phase is dried and concentrated, and then purified by column chromatography with ethyl acetate / petroleum ether to obtain product A;

[0035] Step 2: Add product A to a hydrogen bromide solution with a concentration of 48%, raise the temperature to 80° C. for reflux reaction for 7 hours, and then distill the obtained product under reduced pressure to obtain product B;

[0036] Step 3: Add 100g of the product B prepared in step 2 to hot water at a temperature of 70°C, then ad...

Embodiment 2

[0041] The preparation of diamino flame retardant monomer, the specific preparation process is as follows:

[0042] Step 1: Add 150g of 4-carboxybenzaldehyde and 500g of absolute ethanol into the reaction kettle, raise the temperature to 90°C and then add 197g of diphenylmethylamine and 79.2g of hypophosphorous acid to it, react at constant temperature for 12-14h, and then prepare the product Concentrate, the residue is washed with saturated brine, and then extracted with ethyl acetate, the obtained organic phase is dried and concentrated, and then purified by column chromatography with ethyl acetate / petroleum ether to obtain product A;

[0043] Step 2: Add product A into a hydrogen bromide solution with a concentration of 48%, raise the temperature to 80° C. for reflux reaction for 7 hours, and then distill the obtained product under reduced pressure to obtain a diamino flame-retardant monomer;

Embodiment 3

[0045] The specific preparation method of antibacterial flame retardant modified glass glue is as follows:

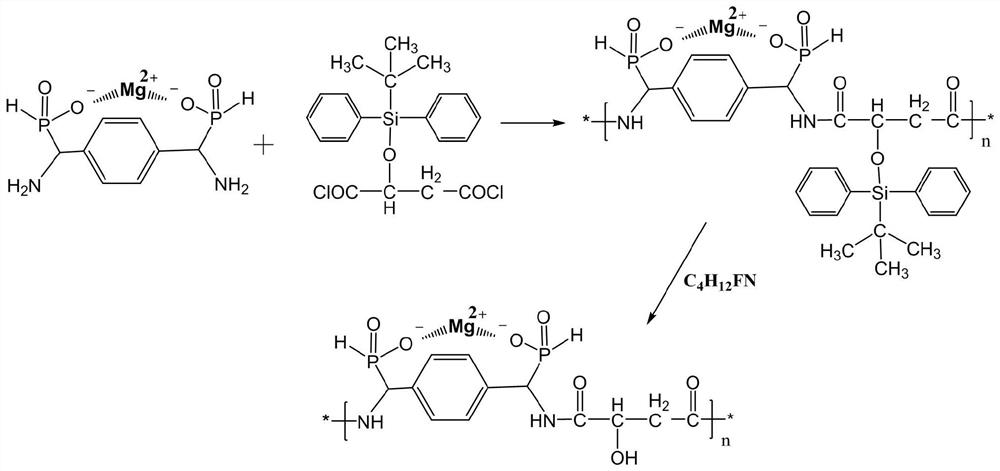

[0046] In the first step, add 460g of the diamino flame retardant monomer prepared in Example 1 and 760g of the diacyl chloride-based monomer prepared in Example 1 into 5kg of water at the same time, raise the temperature to 70°C and stir for 10-12h, then raise the temperature to 90°C to Add 130g of tetramethylammonium fluoride, react at constant temperature for 4 hours, and then conduct evaporation and crystallization to obtain a flame-retardant polymer;

[0047] In the second step, the flame-retardant polymer prepared in the first step is added to 4kg of water, and 180g of 2,3-dimercapto-1-propanol is added thereto at the same time, the temperature is raised to 50°C, and then 80g of catalyst triethylamine is added thereto, After stirring and mixing evenly, add 260 g of toluene diisocyanate dropwise into the reaction vessel, react at constant temperature for 3 hours, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com