Extraction technology for nymphaea alba rhizome extractive

An extraction process and extract technology, applied in the field of white water lily extract, can solve problems such as immature technology, and achieve the effects of strong penetration, improved extraction rate and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

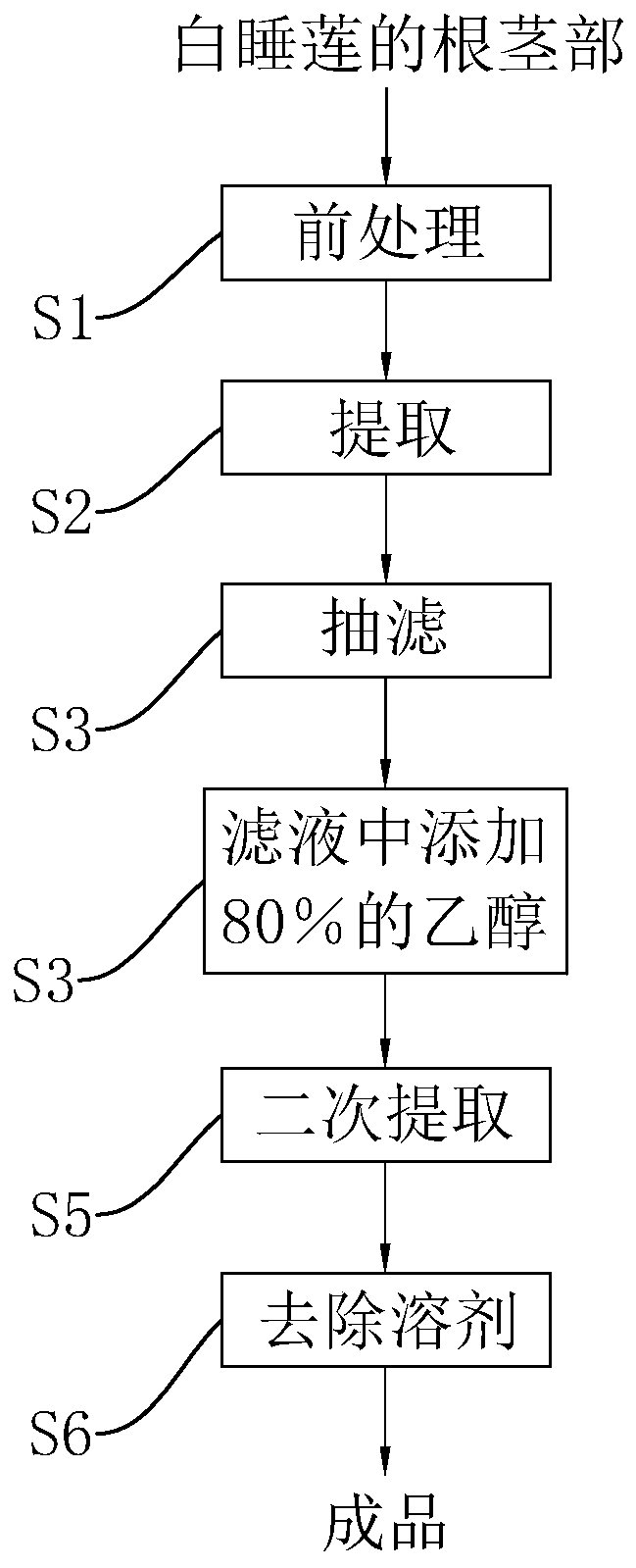

[0041] refer to figure 1 , a kind of extraction process of white water lily rhizome extract, comprises the steps:

[0042] S1: pre-processing. Get the rhizome part of fresh white water lily, and it is washed, air-dried and dried, then pulverized, and pass 80 mesh sieves.

[0043] S2: extraction. The rhizome after the pretreatment of S1 was placed in the extract and soaked for 1.5 hours, and the mass ratio of the extract to the rhizome of White Water Lily was 13:2. After soaking for 1.5h, stir with a glass rod for 30min. The extracting solution includes ethanol solution and ethyl acetate, the mass ratio of ethanol to ethyl acetate is 8:2, and the volume fraction of ethanol is 70%.

[0044] S3: Suction filter the soaking solution after S2 extraction. Also comprise following steps after suction filtration:

[0045] a. Soak the filter residue after S3 suction filtration in a methanol solution with a volume fraction of 70%, and the soaking time is 3 hours.

[0046] b. The so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com