PE film hot sealing bag making machine

A bag-making machine and heat-sealing knife technology, applied in bag-making operations, flexible container manufacturing, paper/cardboard containers, etc., can solve the problems of PE heat-sealing, easy damage, poor heat-sealing effect, etc., to improve The effect of quality, effective heat sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] combine Figure 1 to Figure 6 The PE film heat-sealing bag-making machine of the present invention will be further described.

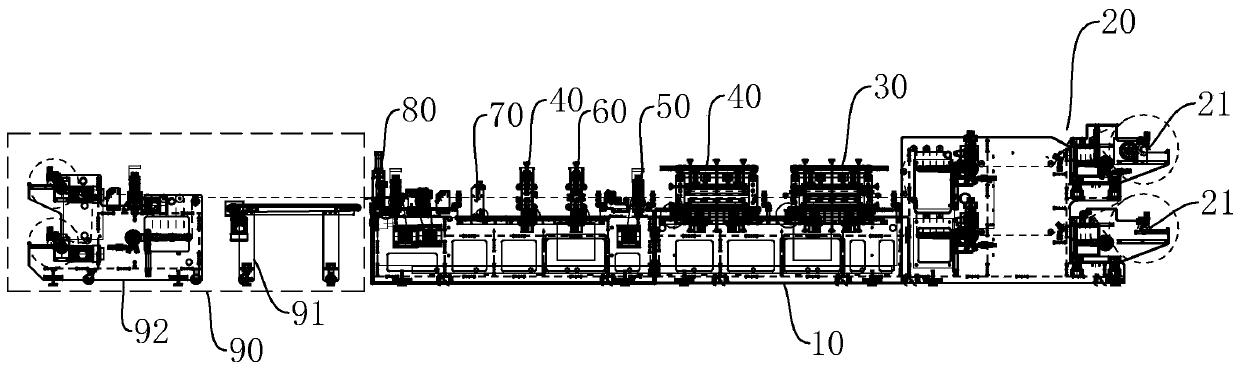

[0034] A PE film heat-sealing bag-making machine, comprising a general frame 10 and a feeding device 20, a horizontal sealing device 30, a pulling device 50, a vertical sealing device 60, a positioning device 70, and a material cutting device sequentially arranged on the general frame 10 80. The receiving device 90, the raw material passes through the above-mentioned devices to form a bag.

[0035] The feeding device 20 has a feeding roller 21 for erecting a raw material roll. In this embodiment, there are two feeding rollers to provide two kinds of raw materials at the same time, and realize the heat sealing of the two kinds of raw materials at subsequent stations;

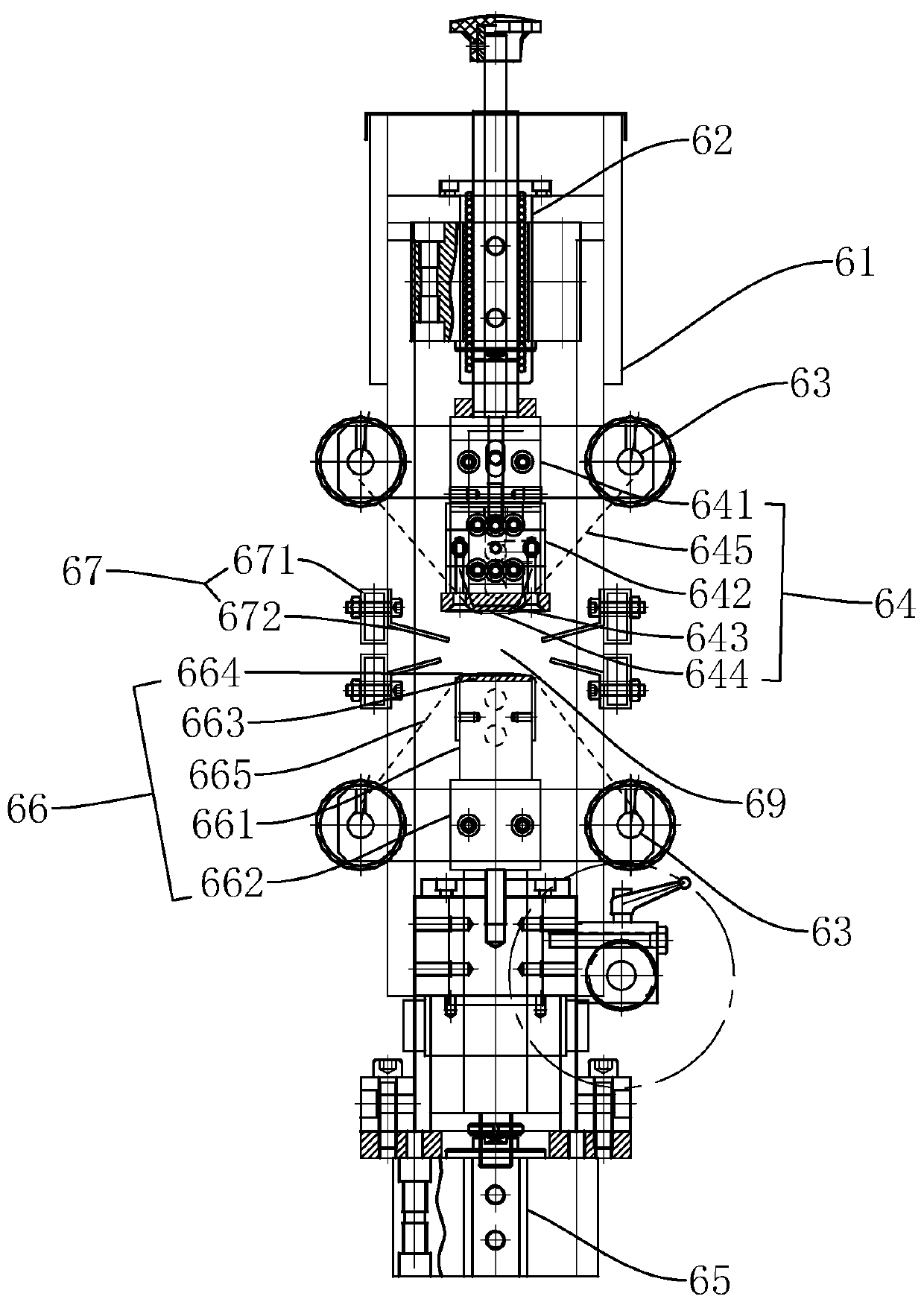

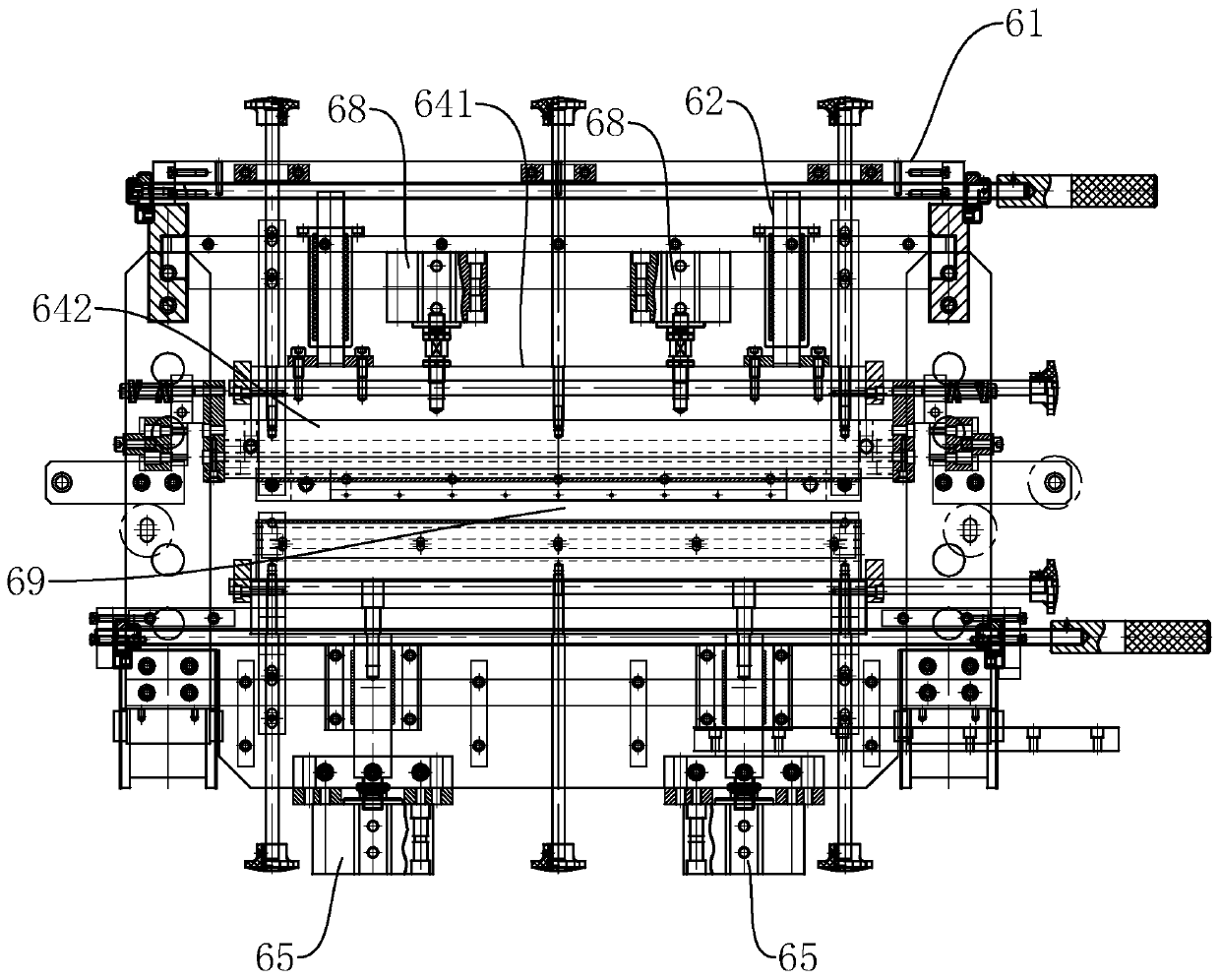

[0036] The horizontal sealing device and the vertical sealing device 60 both include a heat-sealing frame 61 installed on the general frame 10, a first upper lift drive member 68...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com