PVC mixture filter residue recycling method and device

A mixed material and filtered technology, which is applied in the field of recycling and utilization of PVC mixed material filter slag, can solve the problems of environmental pollution and waste, and achieve the effects of simple operation, quality assurance, and elimination of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

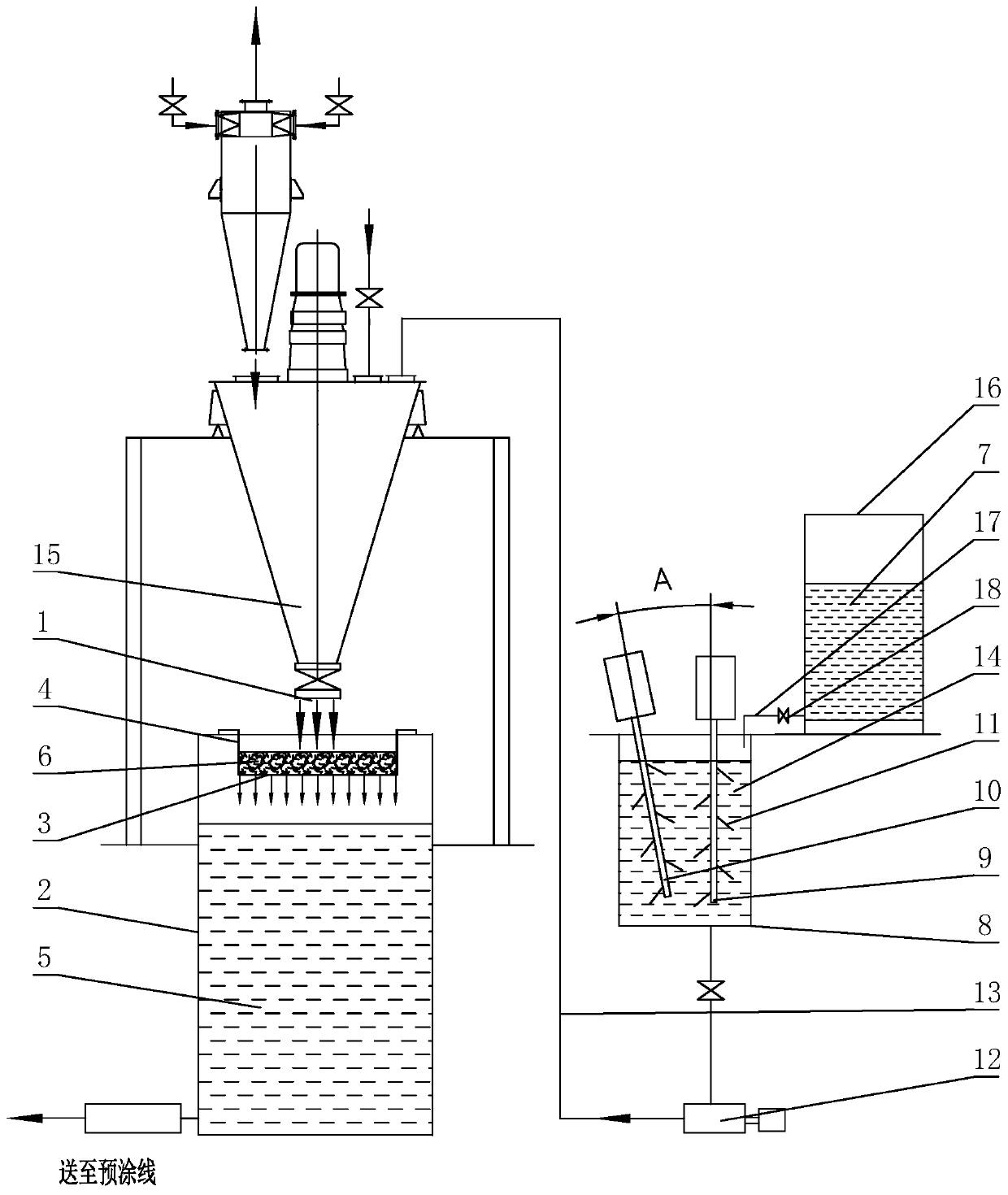

[0009] figure 1 It is a schematic diagram of a method and a device for recycling PVC mixture filter slag. As can be seen from the figure, it is provided with a filter tank 4 with a 30-60 mesh filter screen 3 on the storage tank 2 below the outlet 1 of the stirred tank, so that the PVC mixture coming down from the outlet 1 of the stirred tank 5 After being filtered, go to the storage tank 2 for pre-coating. For the treatment method of the PVC mixture filter residue 6 on the filter screen 3: mix 100 parts of PVC mixture filter residue 6 and 10-15 parts by weight The proportion of DOP oil 7 (dioctyl phthalate) is placed in the mixing tank 8, and the straight stirring rod 9 perpendicular to the horizontal plane in the mixing tank 8 and the angle A with the straight stirring rod 9 is 10°- 30° oblique stirring rod 10 carries out three-dimensional s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com