Three-dimensional surrounding gas shielded welding welding-head

A gas shielded welding and gas shielded technology, applied in welding accessories, electrode characteristics, electrode accessories, etc., can solve problems such as affecting the quality of the weld, affecting the protection effect, shielding gas disturbance, etc., so as to reduce the impact and improve the quality of the weld. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

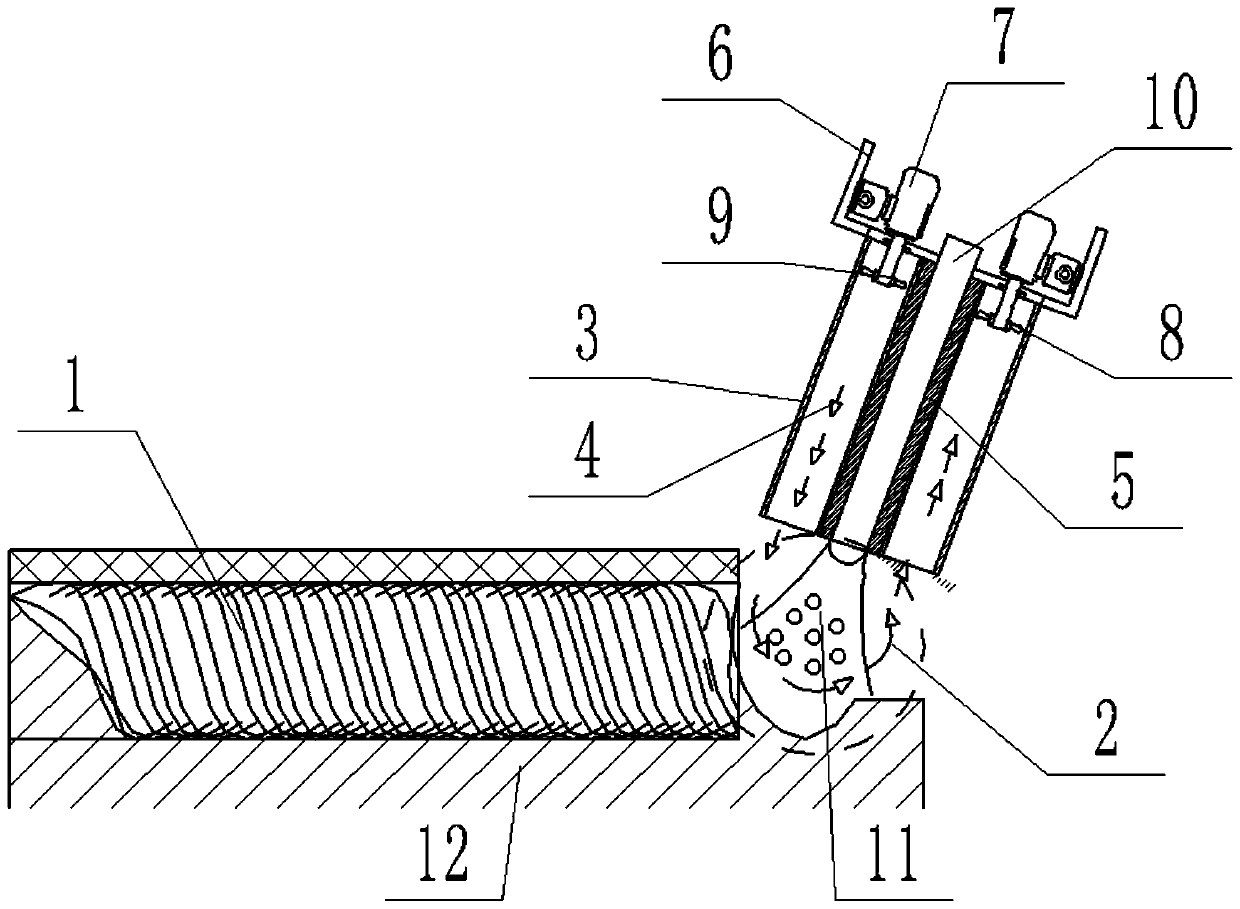

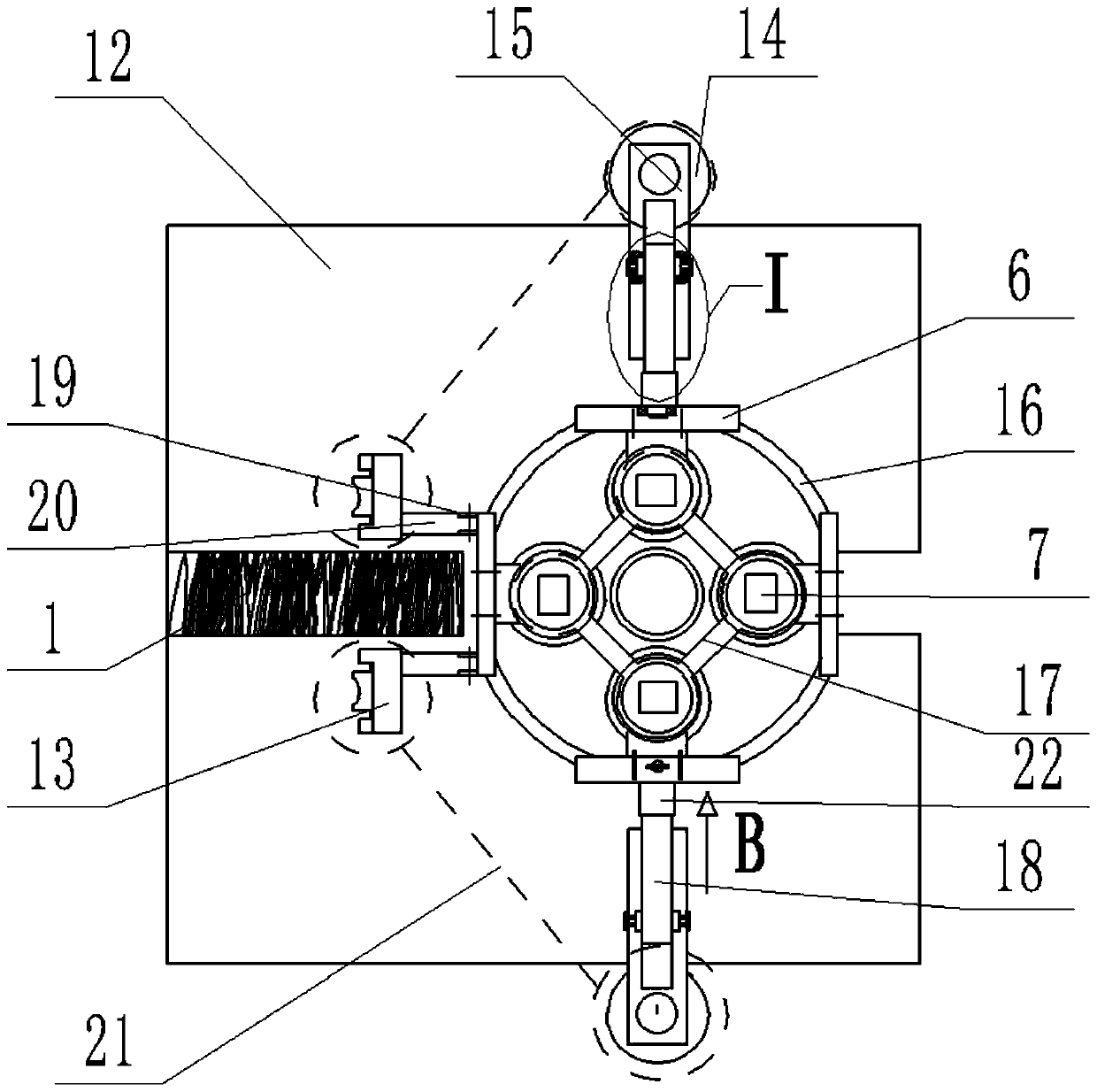

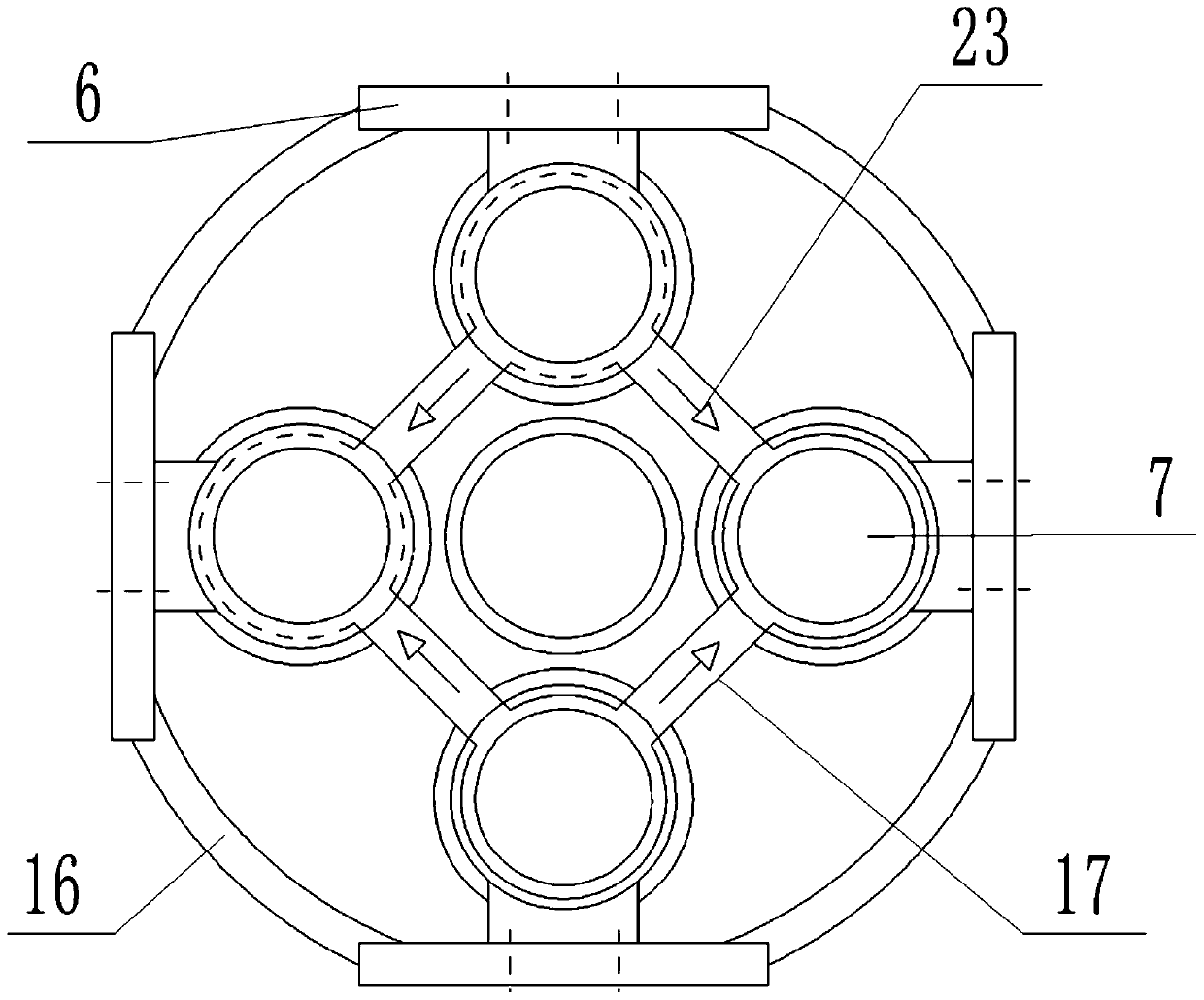

[0025] combine Figure 1-6 , Shown in 8, this patent is described further.

[0026] The present invention is a technical improvement made in the prior art. In the prior art, the welding head includes a shielding gas delivery port for conveying the shielding gas, and a welding wire drum 5 that continuously feeds welding wire 10, and the welding wire 10 is at the bottom of the welding wire drum 5 The end is ignited to generate a welding heat flame 11, and the base metal 12 is welded together; in the prior art, the shielding gas delivery port is set outside the welding wire cylinder 5, so that the shielding gas can protect the welding part of the welding wire 10.

[0027] The welding head provided by the application is provided with a gas cylinder 3 in the prior art, and the gas cylinder mouth is provided between the gas delivery port and the bottom end of the welding wire cylinder 5; there are at least two gas cylinders 3, which are respectively an air supply cylinder and an air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com