Preparation method of bullpaddywack salad

A technology of beef ribs and the production process, which is applied in the direction of freezing/cooling preservation of meat/fish, preservation of meat/fish with chemicals, food science, etc., can solve the problem of broken beef ribs, chewing, and nutrition of beef ribs Problems such as the loss of ingredients, to achieve the effect of solving oxidation blackening, not easy to lose, and difficult to nutrient components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

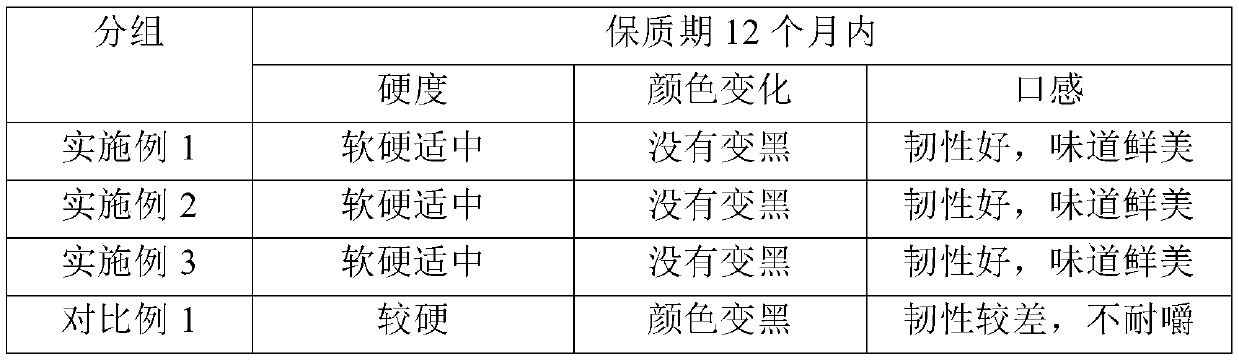

Examples

preparation example Construction

[0026] In the prior art, beef tendon products usually have problems such as hard taste and insufficient freshness. In view of the above problems, the present invention provides a method for preparing beef gluten mixed vegetables with delicious taste and good mouthfeel.

[0027] A preparation method of beef ribs mixed vegetables, the beef ribs mixed vegetables are composed of cooked beef ribs slices, dry seasoning package, compound oil package three packages;

[0028] The preparation method comprises four major steps:

[0029] 1. Preparation of cooked beef tendon slices:

[0030] Weigh the raw beef ribs, thaw, clean and remove the oil and meat on the surface, select the 10-12cm part of the ribs, put cold water into the pot, cook under high pressure, turn off the heat and stew for 60 minutes, remove and cool, drain Dry, remove impurities, slice, vacuum pack the sliced cooked beef tendon slices into bags, and put them in the quick-freezing warehouse for quick freezing to obta...

Embodiment 1

[0043] 1. Preparation of cooked beef tendon slices

[0044] 1. Weigh 250 kg of raw beef ribs, put them into the thawing tank to thaw for 13.5 hours, remove them after thawing, clean up, remove the oil and meat on the raw ribs, and select the middle part of the ribs 10cm after cleaning, and the raw ribs Cut off both ends with a knife;

[0045] 2. After sorting, pour the treated raw gluten into the pot, put cold water into the pot, heat to 95°C under high pressure and cook for 45 minutes, turn off the heat and simmer for 60 minutes;

[0046] 3. Remove and cool, drain for 60 minutes, clean the cooked beef ribs and put them into a slicer for slicing. The thickness of each slice is between 0.8-1mm and the diameter is 4-5cm;

[0047] 4. Measure and pack the sliced cooked beef tendon slices, 165 grams per bag, and use a vacuum machine for vacuum packaging;

[0048] 5. Put the packaged cooked beef tendon slices into the quick-freezing warehouse for quick freezing. The temperature ...

Embodiment 2

[0056] 1. Preparation of cooked beef tendon slices

[0057] 1. Weigh 250 kg of raw beef ribs, put them in the thawing tank to thaw for 13.5 hours, remove them after thawing, clean them, remove the oil and meat on the raw ribs, and select the middle part of the ribs 12cm after cleaning, and the raw ribs Cut off both ends with a knife;

[0058] 2. After sorting, pour the treated raw gluten into the pot, put cold water into the pot, heat to 105°C under high pressure, cook for 45 minutes, turn off the heat and simmer for 60 minutes;

[0059] 3. Remove and cool, drain for 60 minutes, clean the cooked beef ribs and put them into a slicer for slicing. The thickness of each slice is between 0.8-1mm and the diameter is 4-5cm;

[0060] 4. Measure and pack the sliced cooked beef tendon slices, 165 grams per bag, and put them into a vacuum machine for vacuum packaging;

[0061] 5. Put the packaged cooked beef tendon slices into the quick-freezing warehouse for quick freezing. The temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com