Electronic ruler for railway rail joint maintenance and inspection

An electronic and rail technology, used in railway car body parts, railway auxiliary equipment, railway vehicle shape measuring instruments, etc., can solve the problems of inability to measure, low measurement accuracy, etc., to save measurement time, high measurement accuracy, and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

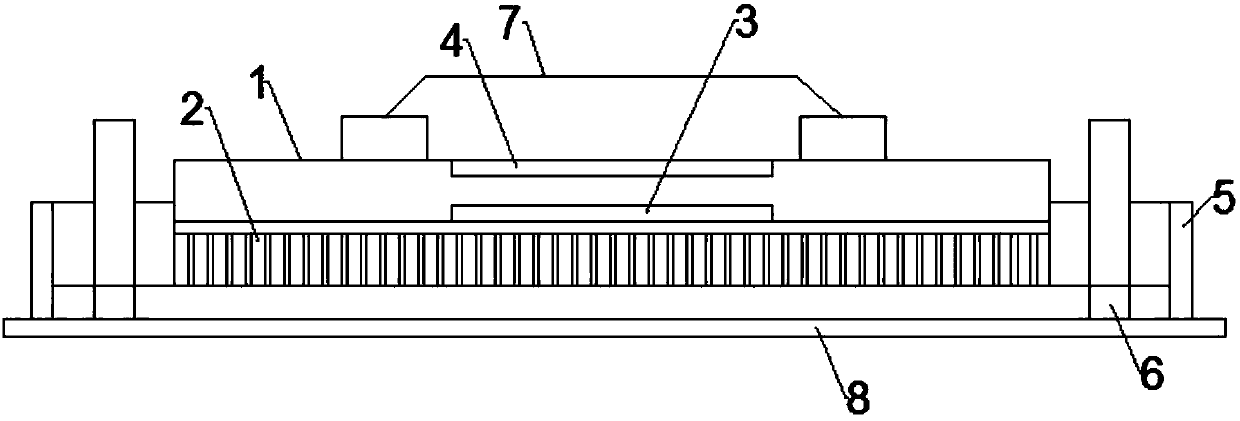

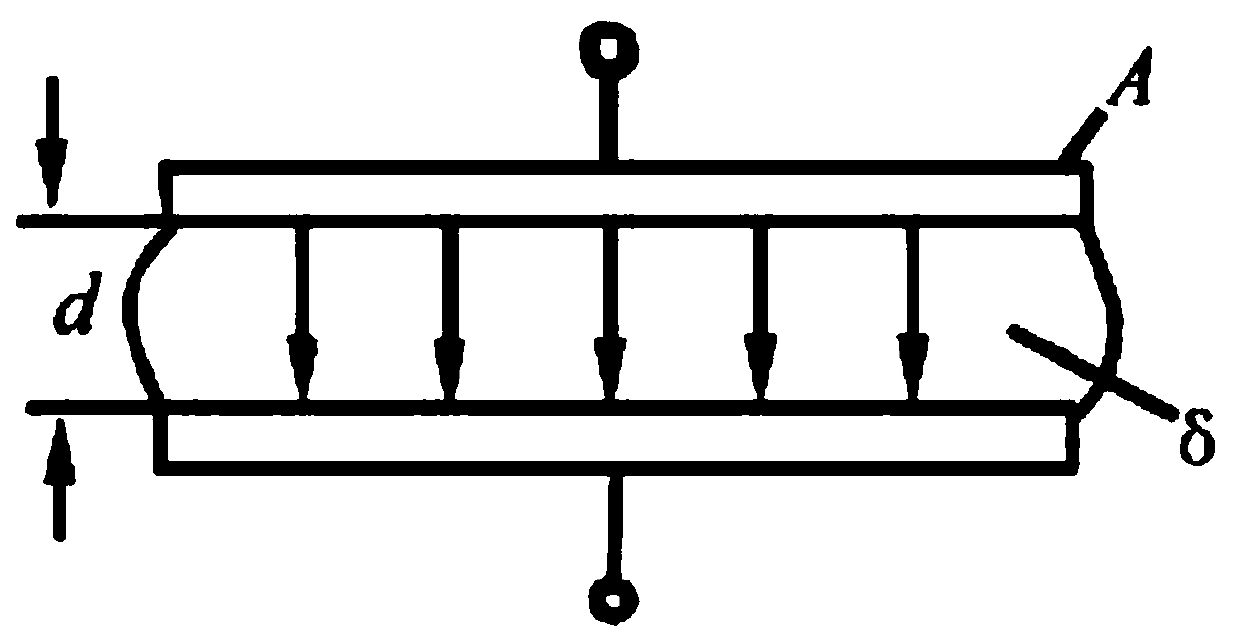

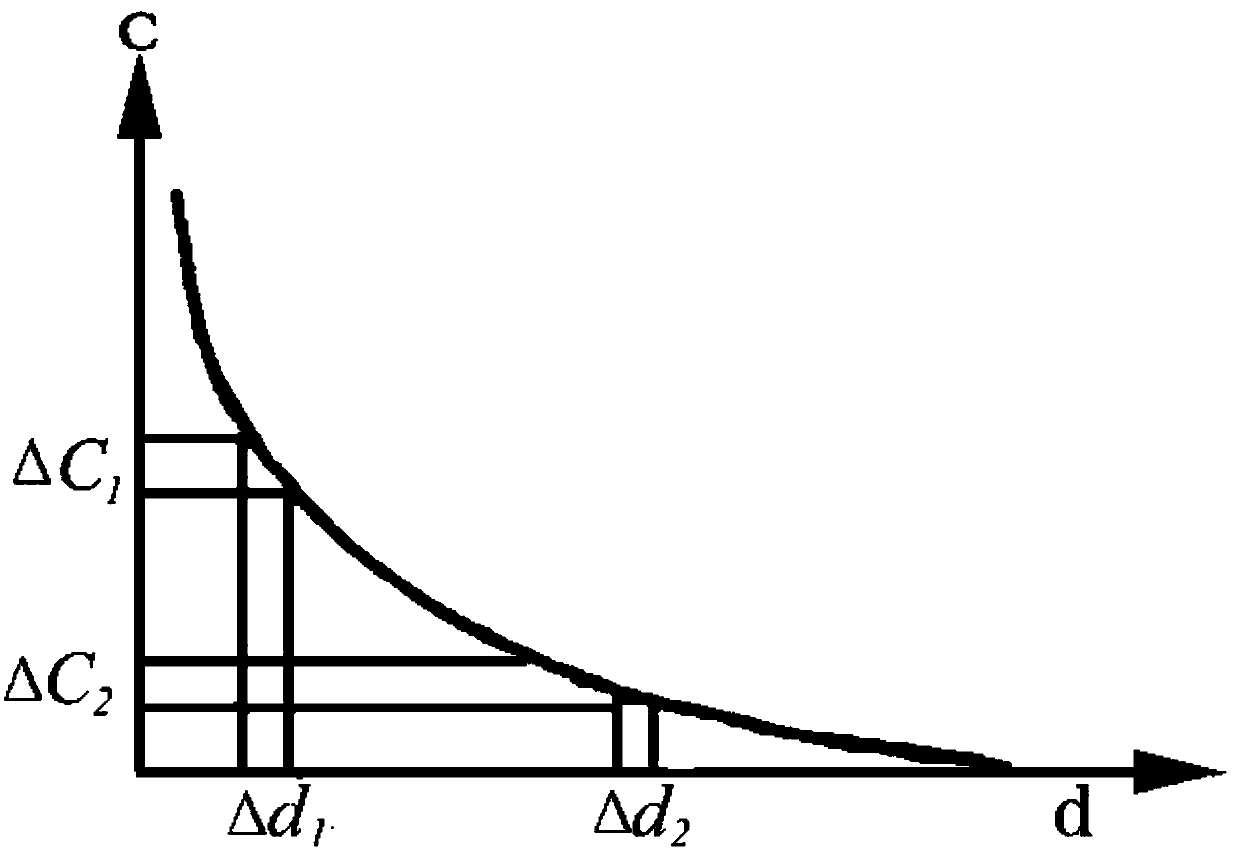

[0056] Such as Figure 1-5 As shown, an electronic ruler for railway rail joint maintenance and inspection includes a case 1 and a measuring device arranged in the case 1, and the measuring device includes an electronic ruler located in the lower layer of the case 1 and a corresponding DSP for controlling the measuring capacitance Processor 2, the electronic ruler includes several plate capacitors 3 arranged in parallel and equidistant, each plate capacitor 3 is connected through the SPI bus, and each plate capacitor 3 is provided with a capacitance measurement point and a capacitance calculation circuit 1. The upper layer of the cabinet 1 is provided with a control processor 4 and a power supply and a signal transmission device connected to the control processor 4. One end of the DSP processor 2 is connected to the electronic ruler by a hard wire, and the other end is connected to the control processor 4.

[0057] The number of plate capacitors 3 on the electronic ruler is 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com