Integrated charging station

A charging station and charging pile technology, applied in the field of integrated charging stations, can solve the problems of insecurity, charging piles with the same height and inapplicability, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

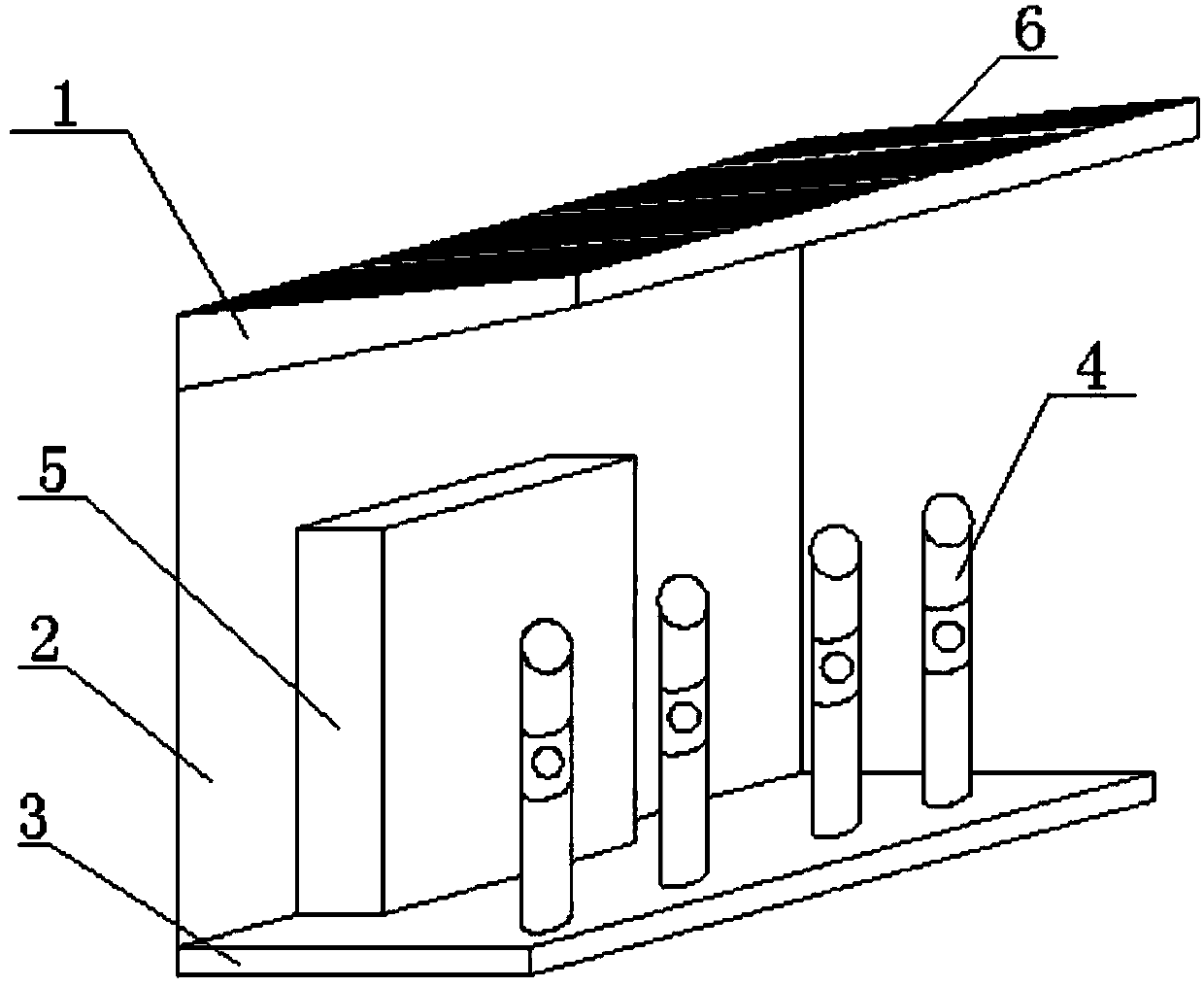

[0019] Such as figure 1 The shown integrated charging station includes a cover top 1, a bottom plate 3, a back plate 2 connecting the cover top 1 and the bottom plate 3, and the bottom of the back plate 2 is perpendicular to the upper surface of the bottom plate 3; the bottom plate 3 is provided with a plurality of charging piles 4, and the charging piles 4 are electrically connected to the charging box 5 arranged inside the backboard 2. The frame composed of the covered top 1, back plate 2 and bottom plate 3 can be integrated. In order to meet the stability and safety of the frame, the frame is a frame welded by steel bars, and the front and rear surfaces of the frame There are front and rear panels with patterns, and at the same time, the upper surface of the cover roof 1 is inclined upward, and the end of the lower surface of the cover roof 1 is inclined downward from the outside to the inside, which can ensure the lighting of the frame. The charging box 5 provided with the...

Embodiment 2

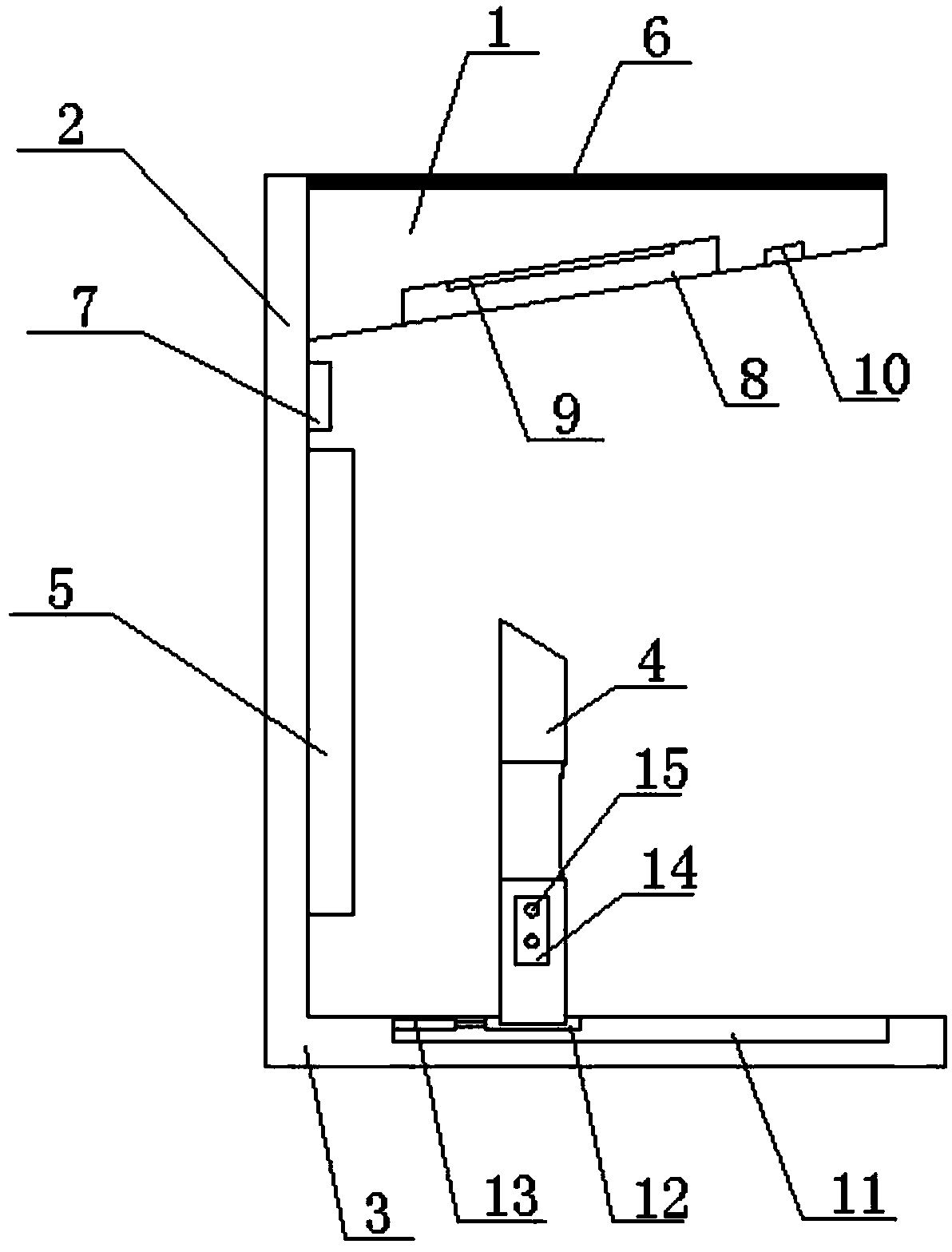

[0021] On the basis of Example 1, such as figure 2 The top of the covered roof 1 shown is inlaid with a solar charging board 6, and the solar charging board 6 is electrically connected to the solar battery 7 arranged on the inner side of the back plate 2. The inner surface of the covered roof 1 is provided with a mounting groove 8, the An LED lamp 9 is arranged in the installation groove 8 , and the LED lamp 9 is electrically connected with the solar battery 7 through a photosensitive switch 10 arranged on the cover top 1 . The solar charging board 6 is obliquely arranged on the top of the cover roof 1, which can fully receive light and improve the efficiency of solar charging. The LED lamp 9 provided can illuminate the charging station at night, and the solar battery is an LED Lamp 9 provides power supply, which is green, environmentally friendly and energy-saving. The photosensitive switch 10 provided with it can detect the intensity of light. When the light intensity is r...

Embodiment 3

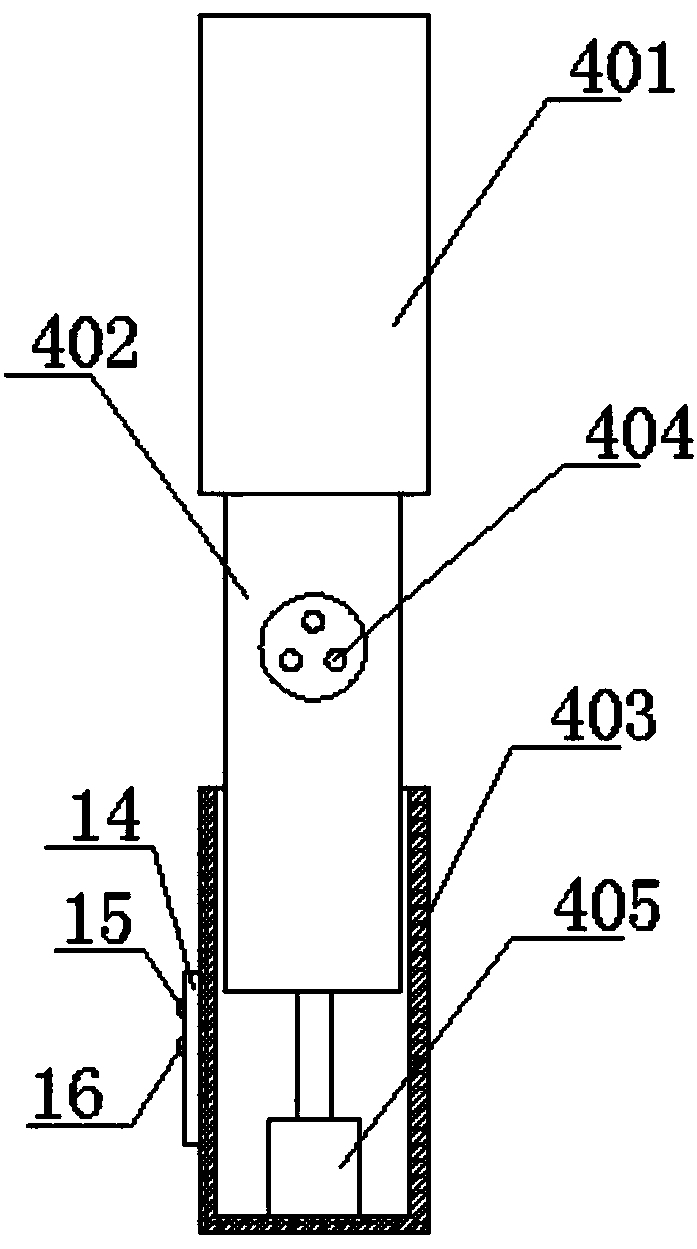

[0023] On the basis of Example 1 and Example 2, as figure 2 The base plate 2 is provided with a plurality of guide rails 11 parallel to each other, and the guide rails 11 are perpendicular to the back plate 2. The guide rails 11 are movably connected with a slide block 12 that moves on the guide rail 11. The slide block The end of 12 is fixedly connected with the telescopic end of the horizontal electric cylinder 13 fixed on one end of the guide rail 11, the charging pile 4 is fixed on the slider 12, and the horizontal electric cylinder 13 and the solar battery 7 are charged through the The horizontal electric cylinder control switch 15 on the pile 4 is electrically connected. The solar battery provides power for the horizontal electric cylinder. When there is a certain distance between the parking position and the charging pile, the horizontal electric cylinder is controlled to expand and contract through the horizontal electric cylinder control button, and then the distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com