Fabricated RC frame structure for arranging buckling-restrained braces (BRB) based on interlayer stiffness demands

A technology of anti-buckling bracing and frame structure, applied in the direction of earthquake resistance, building components, building structure, etc., to achieve the effect of reducing transmission, preventing occurrence and development, and preventing micro-cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

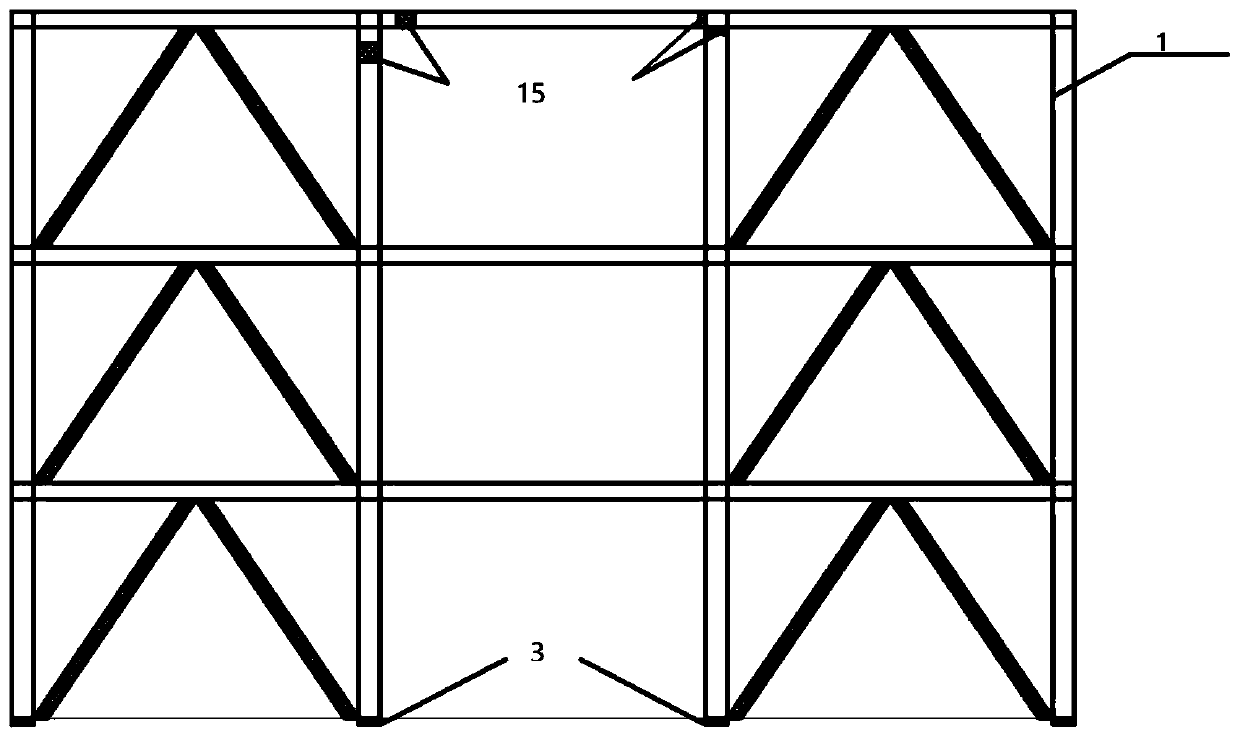

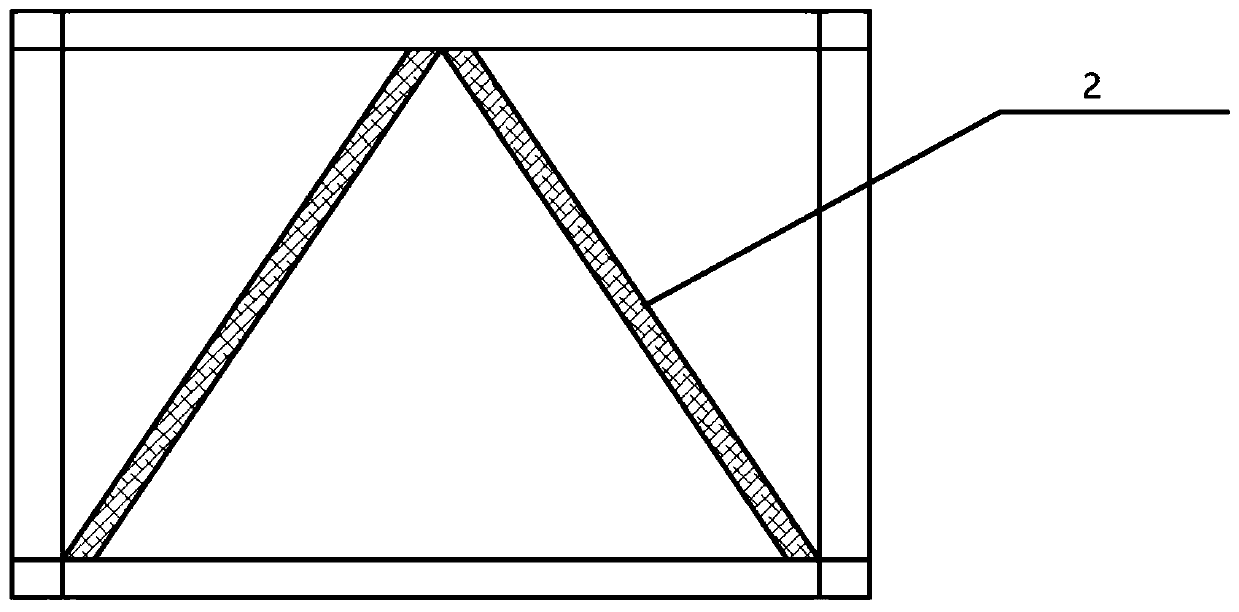

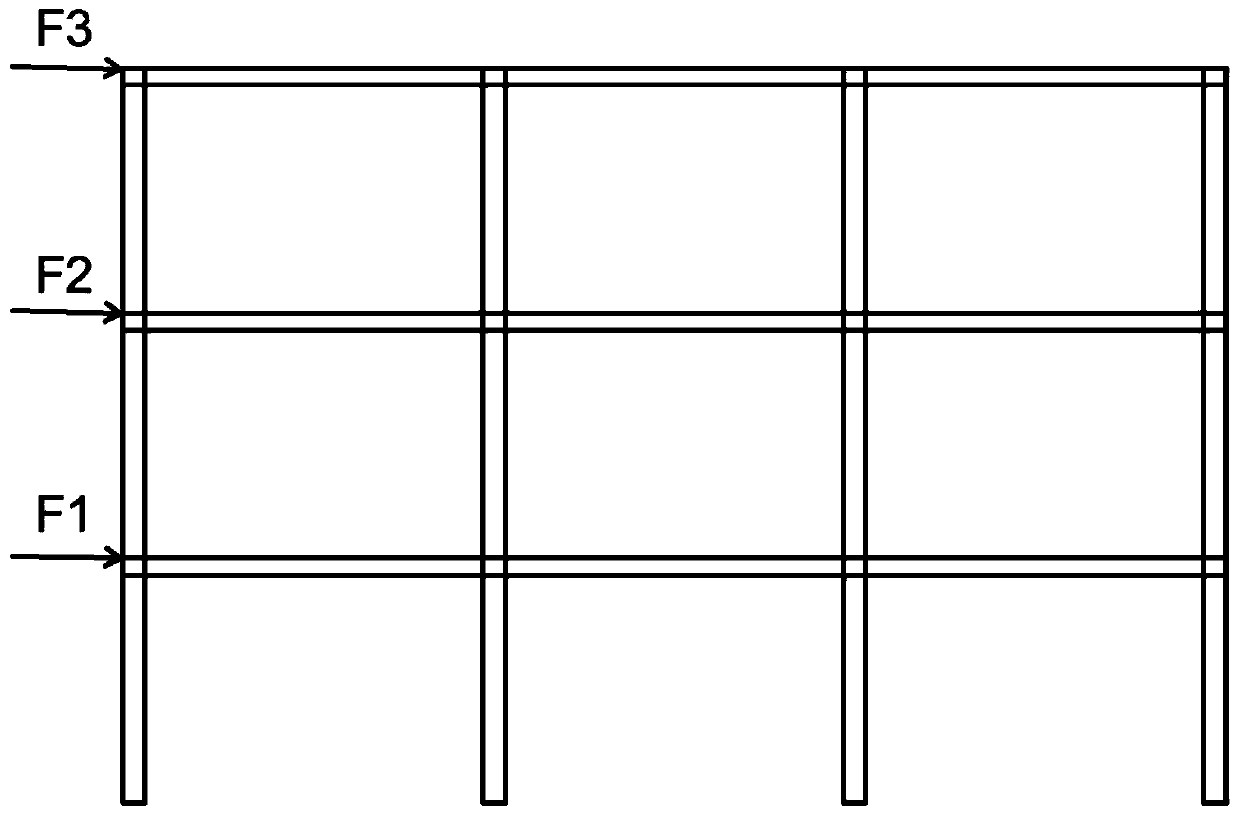

[0053] A prefabricated RC frame structure that needs to be equipped with anti-buckling supports based on interstory stiffness, such as figure 1 As shown, it includes the main structure 1 of the fabricated RC frame, the variable-section buckling-resistant support structure 2, and SMA shock isolators; among them, the variable-section buckling-resistant support structure is a BRB structure, and the cross-sectional size of the BRB core unit is based on the set target The inter-story stiffness depends; the SMA shock isolator includes SMA smart concrete 15 in the beam and column and the SMA rod-assembled self-resetting damper 3 used in the column foot.

[0054] The system integrates the concepts of anti-seismic, shock-absorbing, and shock-isolation, and the addition of anti-buckling braces with variable cross-sections improves the rigidity and overall stability of the structure, enabling uniform damage between layers, avoiding concentrated damage at the bottom layer, and overcoming t...

Embodiment 2

[0076] In the expected plastic hinge area of beams and columns, ECC materials can also be used instead of SMA smart concrete. Using the characteristics of ECC materials for multi-slit steady-state cracking, it can better solve various defects caused by brittleness and weak tensile properties of traditional concrete, and achieve toughness. strengthen.

[0077] All the other are identical with embodiment 1.

Embodiment 3

[0079] The anti-buckling support structure and the main structure are connected by hinges.

[0080] All the other are identical with embodiment 1.

[0081] The present invention lays out the anti-buckling supports according to the requirement of determining the interstory stiffness, and can set the target interstory stiffness according to the actual needs, so that the RC frame has a consistent displacement between the floors, so that the structural system will not be damaged due to the bottom layer under the action of the earthquake. Large and resulting overall collapse. Use SMA intelligent concrete pouring in the expected plastic hinge area and beam-column ends and other vulnerable areas, and use ordinary concrete pouring in other areas, which can exert the self-resetting and self-repairing performance of SMA materials, inhibit the further development of cracks in the damaged area, and realize the self-healing of cracks . SMA dampers are used at the base of the column to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com