A preparation method of large-thickness fiber fabric prepreg for non-metallic composite materials

A technology of fiber fabrics and composite materials, which is applied in the processing of textile materials, fiber processing, textiles and papermaking, etc. It can solve the problems of not being widely used, not realizing mass production, and difficulty in resin pre-impregnation, etc., and achieves good infiltration effect , Solve the difficulty of impregnation and the effect of uniform resin infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

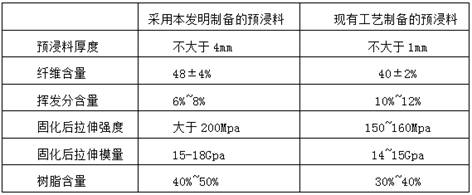

Image

Examples

Embodiment 1

[0025] Wetting agent preparation:

[0026] According to the weight ratio of boron phenolic resin: absolute ethanol 1:0.5~1, weigh boron phenolic resin and absolute ethanol, then put the absolute ethanol into the mixing tank and preheat it, and heat up at a rate of 1~2°C / min To 55 ℃, keep warm for 30min. After the absolute ethanol is preheated, add the boron phenolic resin particles into the mixing tank, start stirring at 55°C, the stirring speed is 25r / min, and the stirring time is not less than 2h, until there is no visible suspended matter in the mixed glue; Wetting agent; wetting agent should be stored below room temperature.

[0027] Clean the surface of the dipping equipment to ensure that the equipment is operating normally and the temperature is controllable and accurate within ±1°C; and lay a layer of release paper on the surface of the equipment; cut the glass fiber fabric or quartz fiber fabric of the required size, and put Spread the fiber fabric on the release pa...

Embodiment 2

[0031] According to the weight ratio of boron phenolic resin: absolute ethanol 1:0.5~1, weigh boron phenolic resin and absolute ethanol, then put the absolute ethanol into the mixing tank and preheat it, and heat up at a rate of 1~2°C / min To 60 ℃, keep warm for 30min. After the absolute ethanol is preheated, add the boron phenolic resin particles into the mixing tank, start stirring at 60°C, the stirring speed is 30r / min, and the stirring time is not less than 2h, until there is no visible suspended matter in the mixed glue; Wetting agent; wetting agent should be stored below room temperature.

[0032] Clean the surface of the dipping equipment to ensure that the equipment is operating normally and the temperature is controllable and accurate within ±1°C; and lay a layer of release paper on the surface of the equipment; cut the glass fiber fabric or quartz fiber fabric of the required size, and put Spread the fiber fabric on the release paper on the table top of the dipping e...

Embodiment 3

[0036] According to the weight ratio of boron phenolic resin: absolute ethanol 1:0.5~1, weigh boron phenolic resin and absolute ethanol, then put the absolute ethanol into the mixing tank and preheat it, and heat up at a rate of 1~2°C / min To 65 ℃, keep warm for 30min. After the absolute ethanol is preheated, add the boron phenolic resin particles into the mixing tank, start stirring at 65°C, the stirring speed is 35r / min, and the stirring time is not less than 2h, until there is no visible suspended matter in the mixed glue; Wetting agent; wetting agent should be stored below room temperature.

[0037] Clean the surface of the dipping equipment to ensure that the equipment is operating normally and the temperature is controllable and accurate within ±1°C; and lay a layer of release paper on the surface of the equipment; cut the glass fiber fabric or quartz fiber fabric of the required size, and put Spread the fiber fabric on the release paper on the table top of the dipping e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com