Method and device for determining working modes of pipeline and storage medium and processor

A technology for working mode and determination method, applied in the direction of conveyor control device, conveyor objects, transportation and packaging, etc., can solve the problems of complexity, inefficiency, low flexibility of material buffer conveyor line, etc., and achieve low flexibility , the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

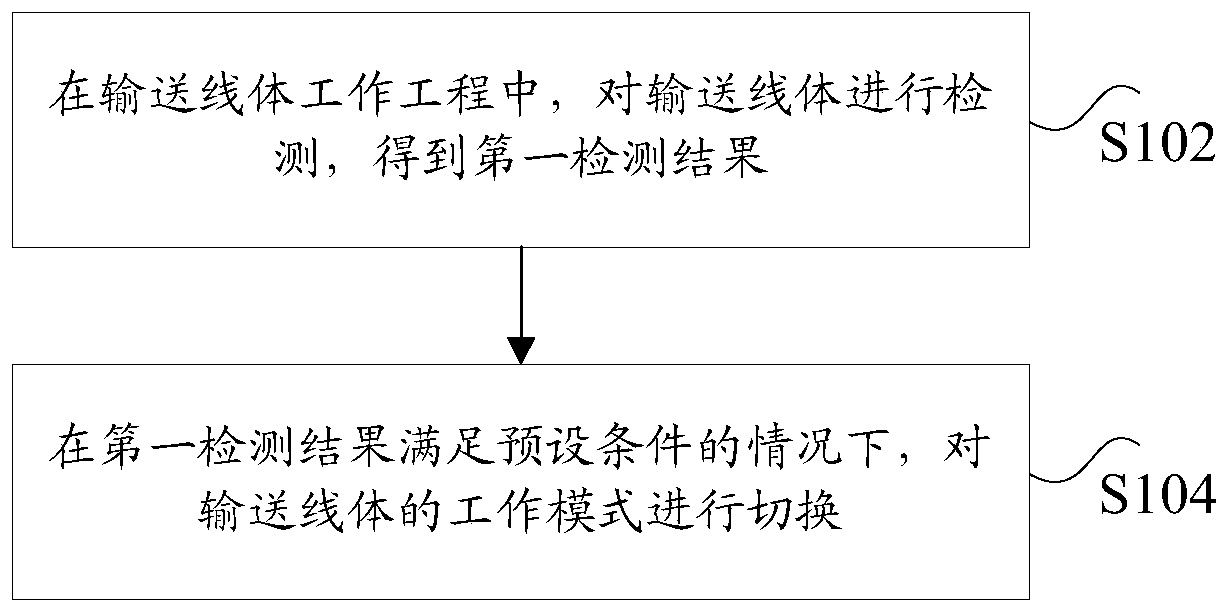

[0044] According to an embodiment of the present invention, a method embodiment of a method for determining the working mode of a conveying line is provided. It should be noted that the steps shown in the flow chart of the accompanying drawings can be implemented in a computer system such as a set of computer-executable instructions and, although a logical order is shown in the flowcharts, in some cases the steps shown or described may be performed in an order different from that shown or described herein.

[0045] figure 1 is a flow chart of a method for determining the working mode of a conveying line according to an embodiment of the present invention, such as figure 1 As shown, the method for determining the working mode of the conveyor line includes the following steps:

[0046] In step S102, in the work process of the conveying line, the conveying line is detected, and a first detection result is obtained.

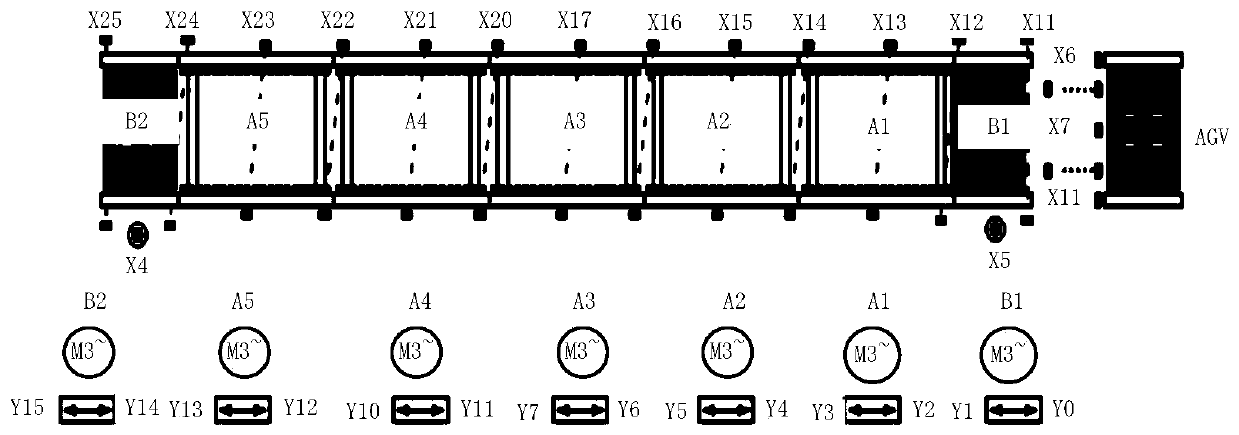

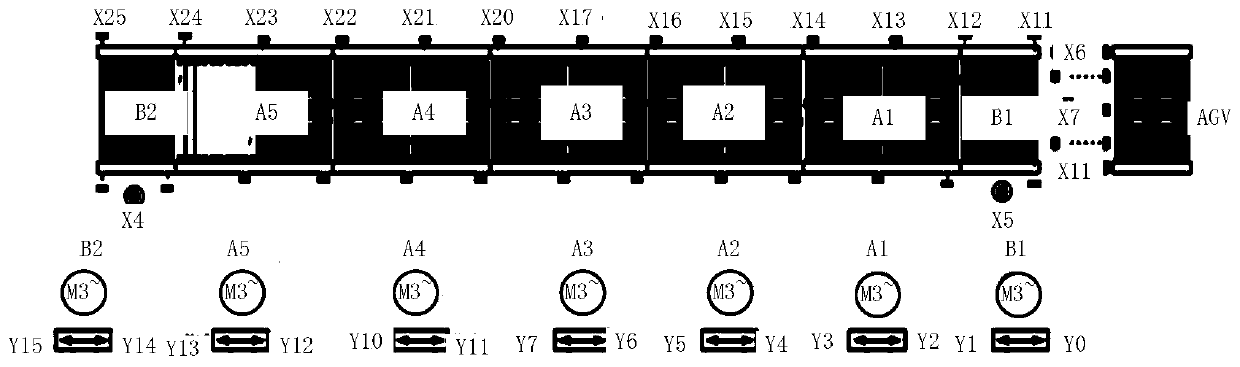

[0047] Specifically, the above-mentioned conveying line body ...

Embodiment 2

[0077] According to another aspect of the embodiment of the present invention, a device for determining the working mode of the transmission line is also provided,

[0078] Image 6 is a schematic diagram of a device for determining the working mode of a conveying line according to an embodiment of the present invention, such as Image 6 As shown, the device for determining the working mode of the conveyor line includes:

[0079] The detecting unit 61 is configured to detect the conveying line body during the working process of the conveying line body, and obtain a first detection result.

[0080] The switching unit 63 is configured to switch the working mode of the transmission line body when the first detection result meets the preset condition, wherein the working mode includes: buffer mode and priority mode, and the buffer mode is used to indicate that the transmission line body The materials on the conveyor line are cached, and the priority mode is used to indicate the ...

Embodiment 3

[0095] According to another aspect of the embodiments of the present invention, a storage medium is also provided, and the storage medium includes a stored program, wherein the program executes the method for determining the working mode of the transmission line in any one of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com