Beverage bottle recycling device

A recovery device and beverage bottle technology, applied in the direction of plastic recycling, recycling technology, presses, etc., can solve the problems of difficult recycling of plastic bottles, relying on manual recycling, and low recycling rate of plastic products, achieving simple structure, Reasonable design and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

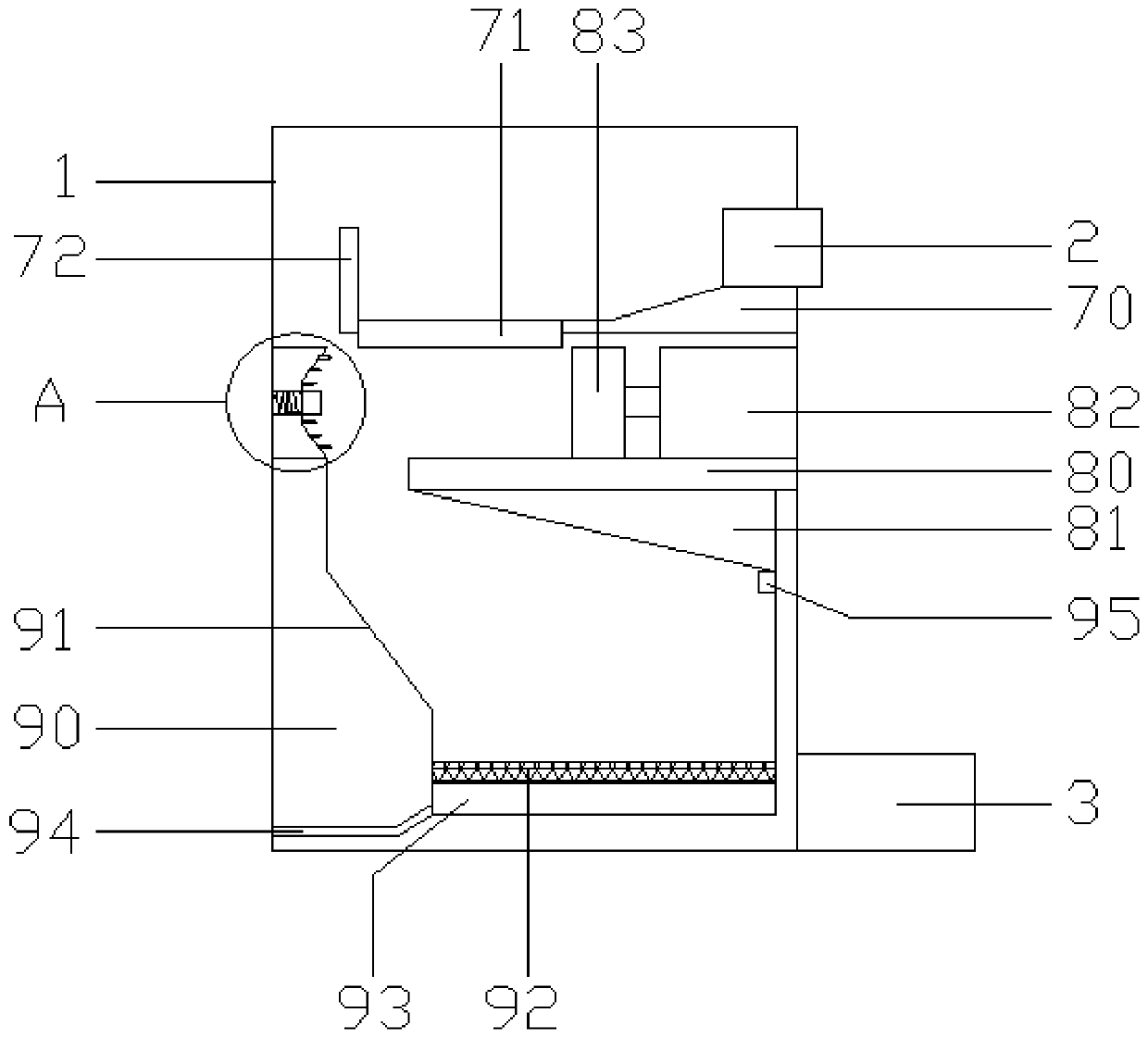

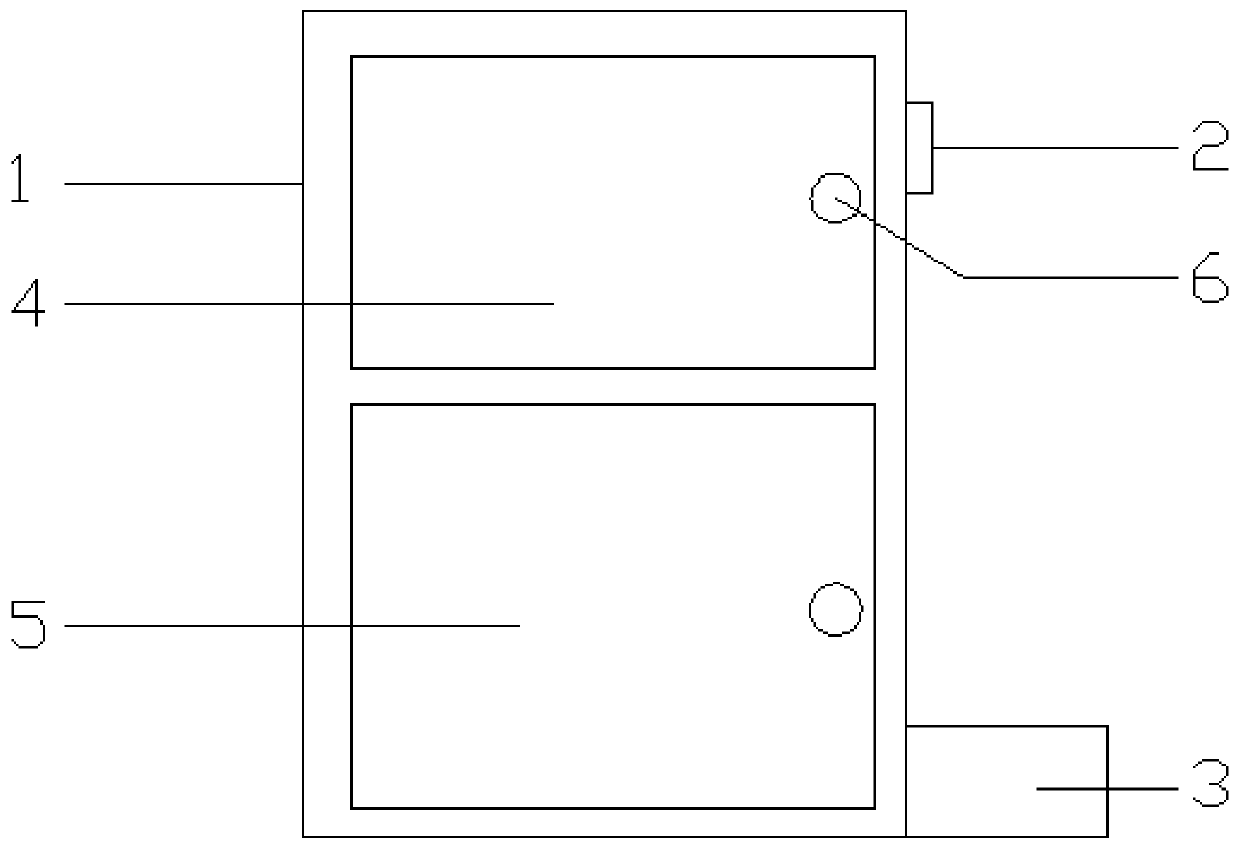

[0015] Referring to the accompanying drawings, a beverage bottle recovery device of the present invention includes a device main body 1, a bottle inlet 2, a backing plate 3, a maintenance door 4, a recovery bin door 5, a lock head 6, a feeding mechanism 7, a compression mechanism 8 and a storage mechanism 9. The right side of the main body 1 of the device is provided with a bottle inlet 2, a backing plate 3 is provided under the bottle inlet 2, and a maintenance door 4 is provided on the outer wall of the main body 1 of the device, and the maintenance door 4 A recovery bin door 5 is provided below, a lock head 6 is provided on the maintenance door 4 and the recovery bin door 5, and a feeding mechanism 7, a compression mechanism 8 and a storage mechanism 9 are sequentially arranged inside the device main body 1 from top to bottom.

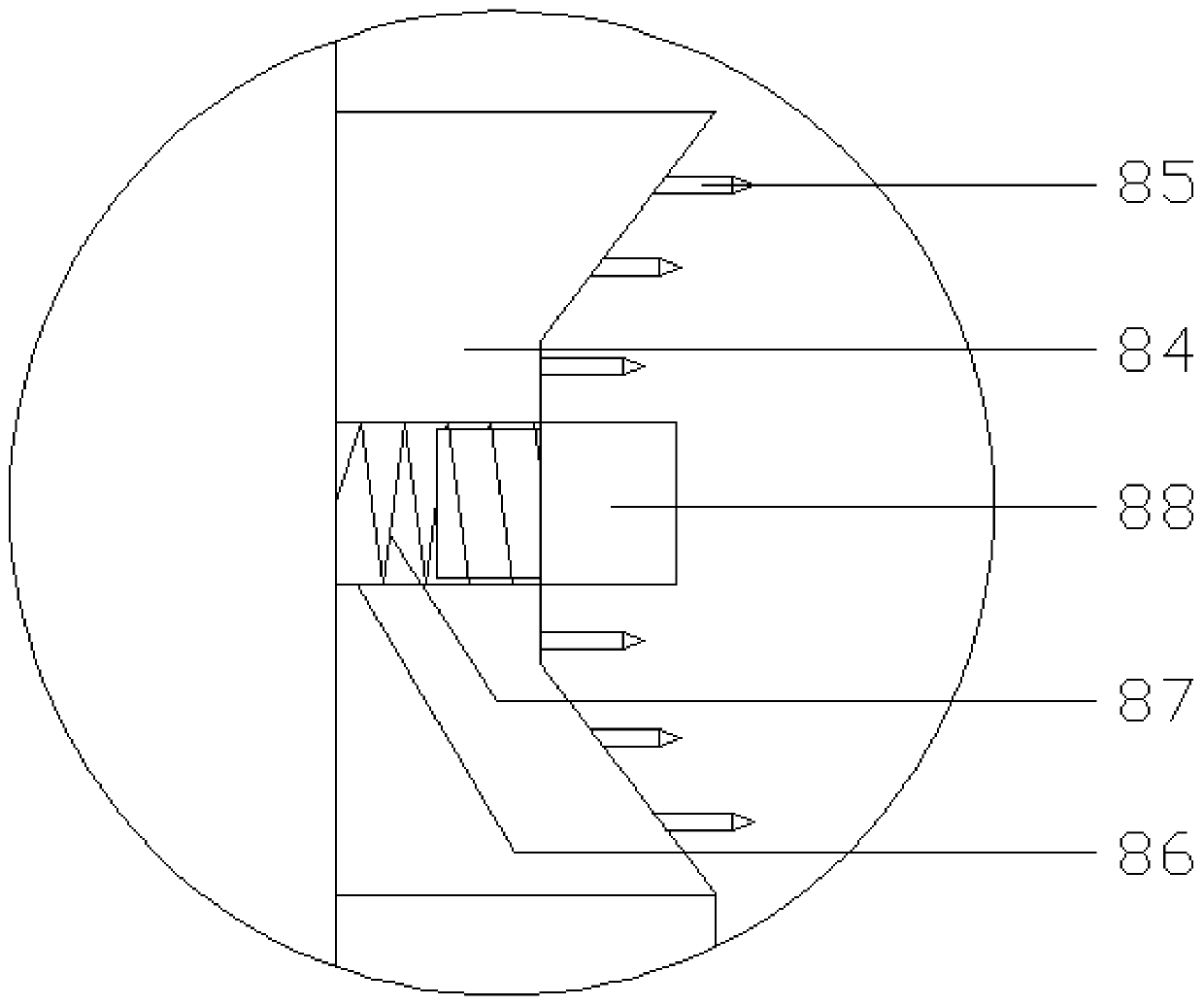

[0016] Wherein, the feeding mechanism 7 includes a feeding slope 70, a blanking slope 71 and a limit baffle 72, the feeding slope 70 is located dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com