Dimension measuring system for large-format plate materials and measuring method thereof

A measurement system and measurement method technology, applied to measurement devices, optical devices, instruments, etc., can solve problems such as difficulty in ensuring that the positional relationship between cameras will not change slightly, a single camera's insufficient field of view, and angle errors of captured images, etc. Achieve the effect of meeting the needs of measurement scenarios, promoting production automation, and having high versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

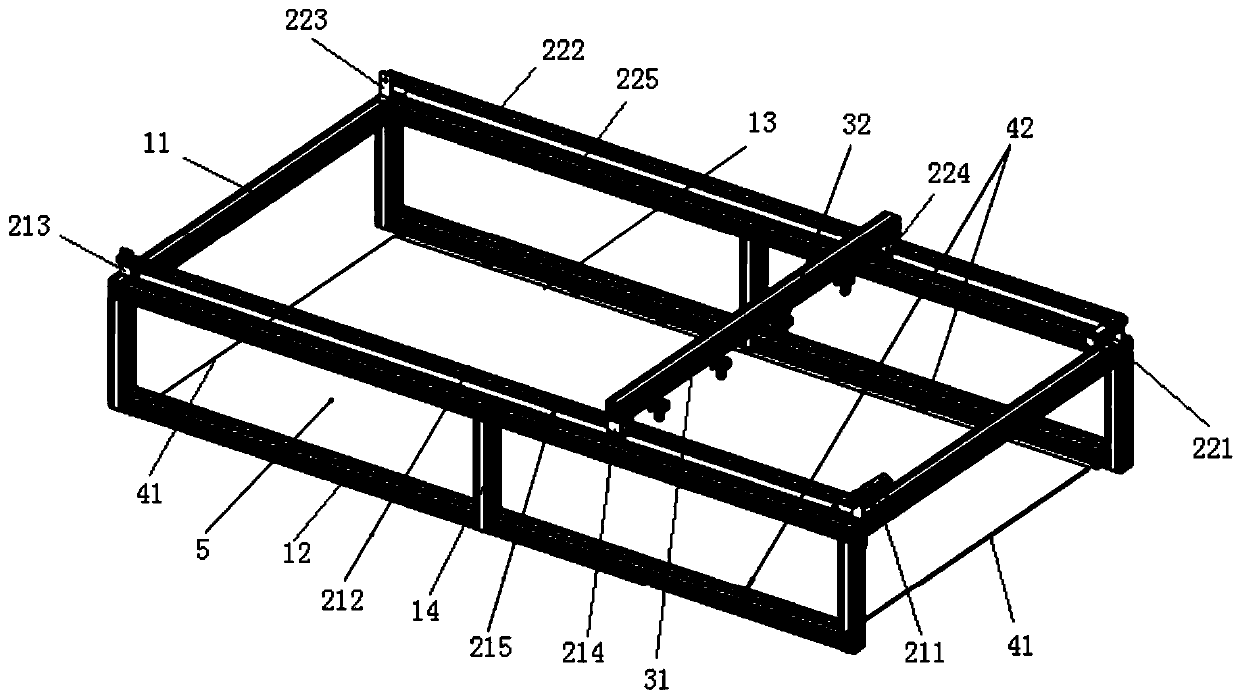

[0043] see figure 1 , the embodiment of the present invention includes:

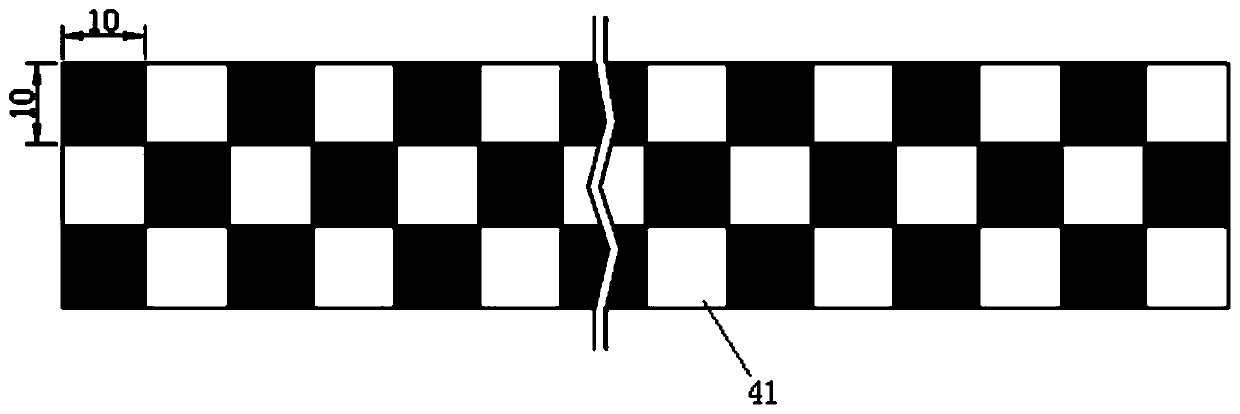

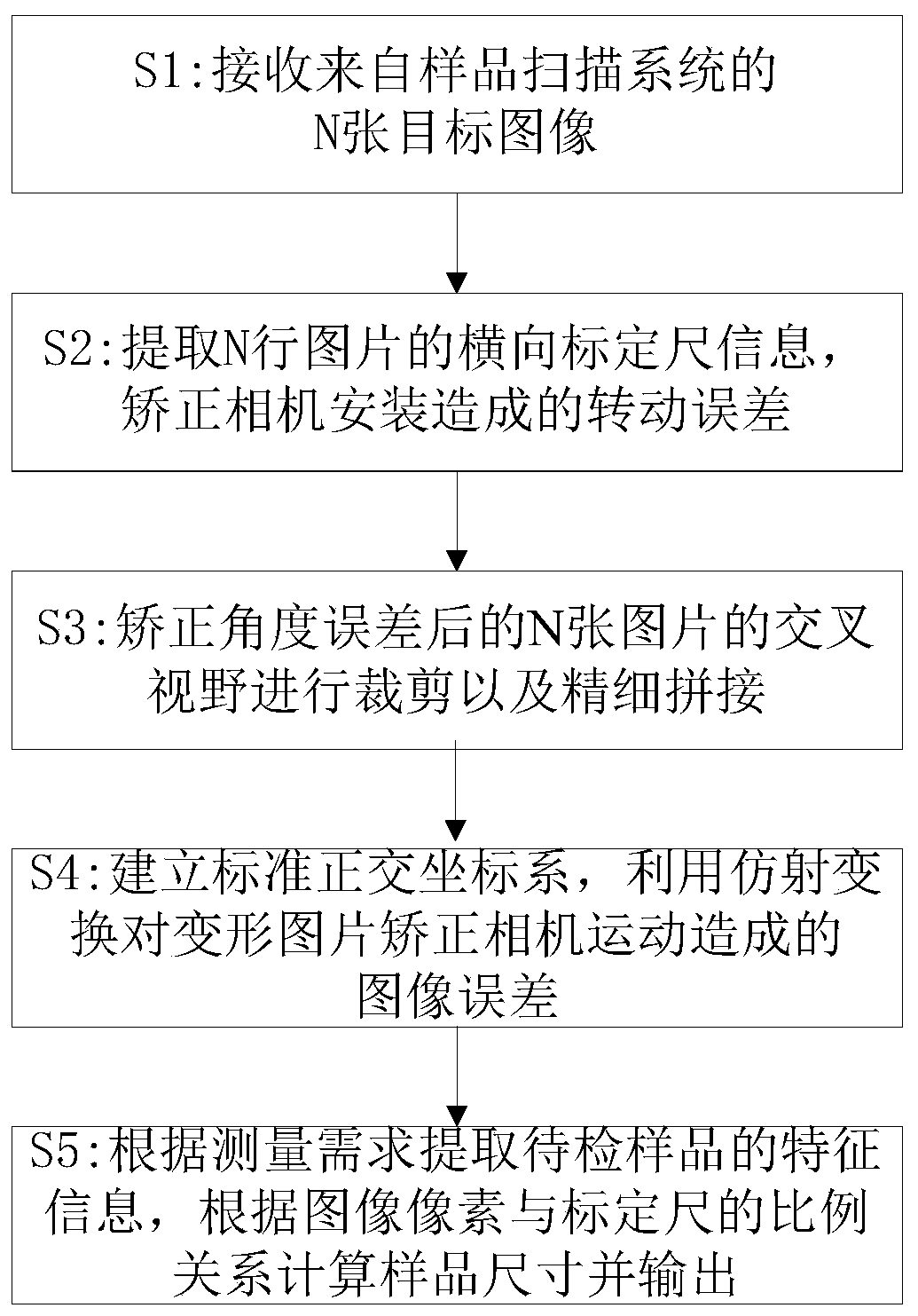

[0044]A size measurement system for large panel materials mainly includes a three-dimensional support, a traction and moving device, a sample scanning system, a calibration system, and a main control system. The three-dimensional support is used as the operating frame of the large-format size measurement system; the traction and moving device is installed on the three-dimensional support as a driving device for the large-format size measurement system; the sample scanning system is used as a large-format size measurement system. The scanning and shooting system of the syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com