Socket pipe, pipe with socket pipe, and pipe connection structure using socket pipe

A pipe connection and socket technology, which is applied in the field of socket pipes, can solve the problems of inability to be popularized in a wide range, unfavorable manufacturability and economy, difficulty in using mechanical connections, etc., and achieve good sealing, prevent separation, and stabilize the joint state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] 以下,参照附图,将详细说明本发明的优选实施方式。作为参考,为了说明本发明的实施方式而参考的附图中,构成要素的大小或线的厚度等为了方便理解而可能会被有些夸张地表现。此外,用于说明本发明的实施方式的用语主要是考虑在本发明中的功能而定义的,因此,可以根据使用者、运用者的意图、惯例等而有所不同。因此,针对用语,应基于本说明书的整个内容进行解释。

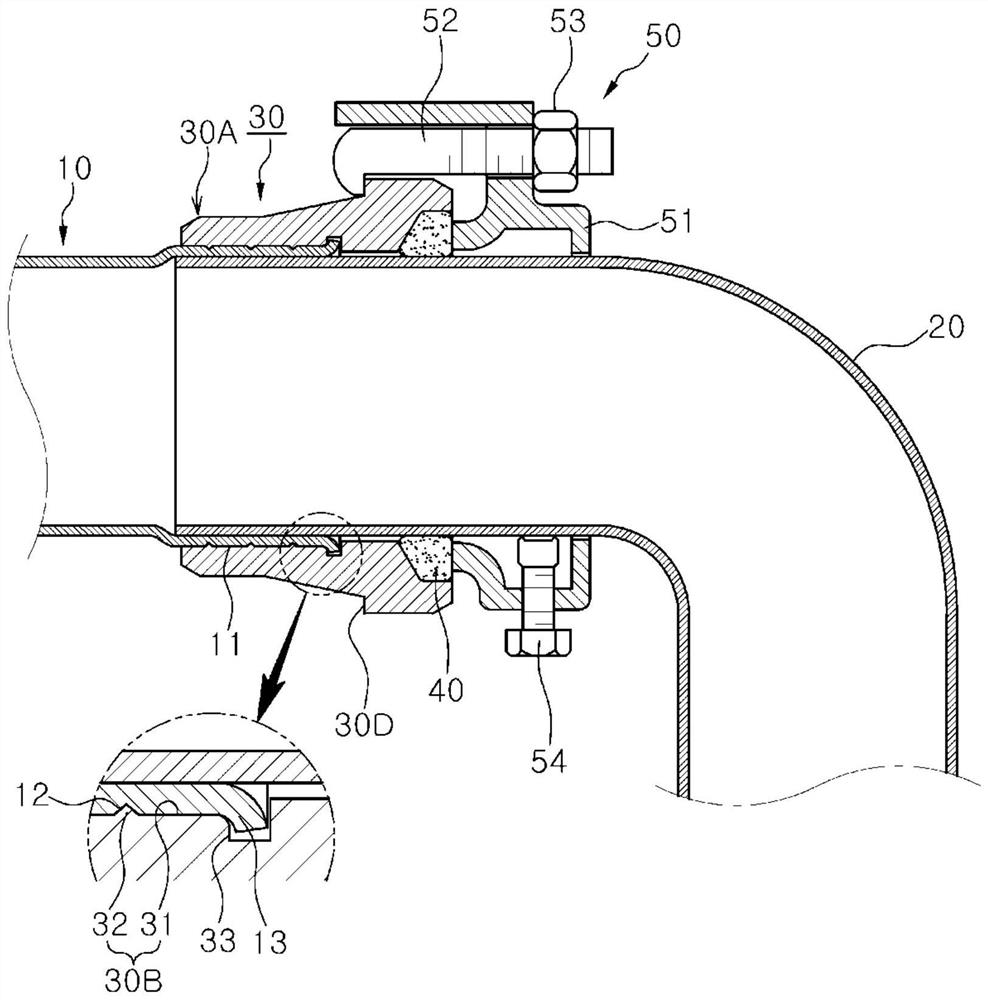

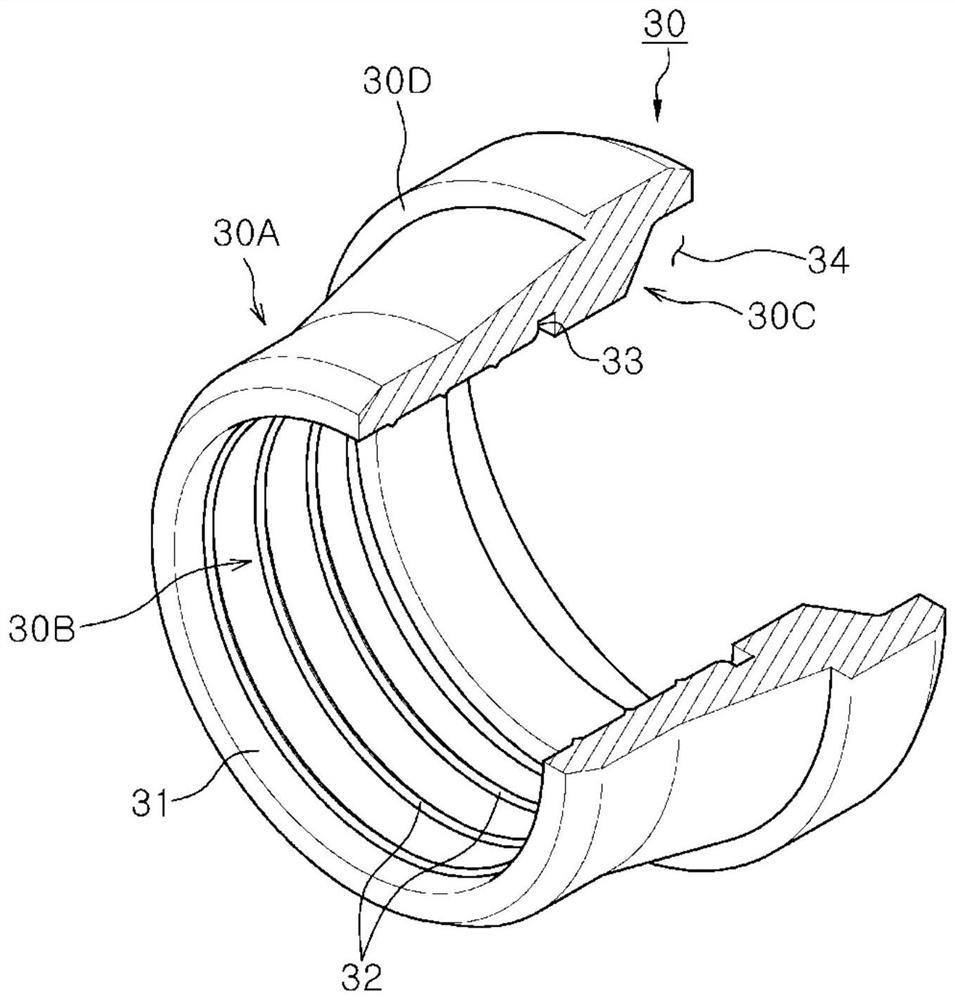

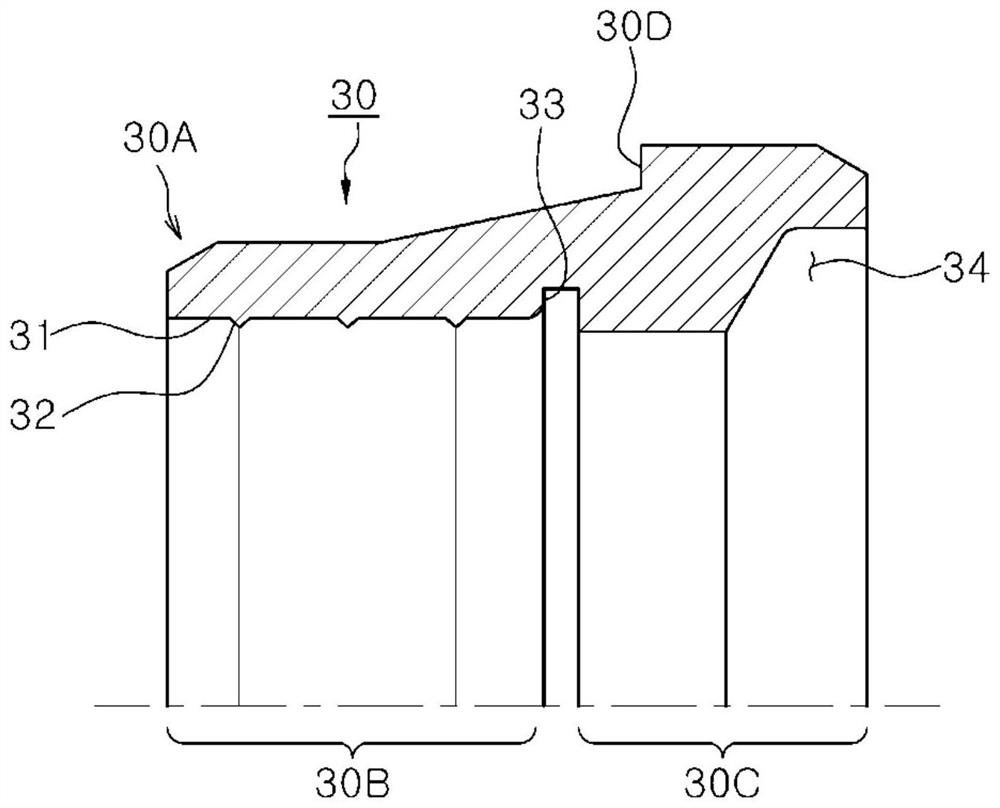

[0062] figure 1 为示出利用本发明第一实施例中的插口管(参照附图标记30)的管连接结构的示意图, figure 2 and image 3 show figure 1 中的插口管的结构。

[0063] refer to figure 1 ,附图标记10和20为要相互连接的一侧的第一管和另一侧的第二管,根据本发明第一实施例的管连接结构,所述第一管10和第二管20以机械连接方式相互连接。并且,为此,本发明第一实施例中的管连接结构包括:插口管30,其提供用于相互连接管的插口;管密封部件40,用于保持管相互连接时的密封状态;结合装置50,用于维持管之间的相互连接。

[0064] 根据材质,第一管10和第二管20可以是由包括钢(steel)、铁(iron)、不锈钢(stainless steel)或铝(aluminium,Al)等的金属材质形成的管,也可以是由合成树脂等非金属材质形成的管。第一管10与第二管20可以是相同材质的管,也可以是不同材质的管。

[0065] 再者,根据形态,第一管10及第二管20可以是直管,也可以是弯管或T 型管等异型管。并且,其横截面可以是圆形,也可以是四边形等多边形。第一管10与第二管20的形状可以是相同的,也可以是不同的。

[0066] Such as Figure 1 to Figure 3 所示,插口管30包括管连接部30B及管接续部30C。附图标记30A为具有管结构的插口管本体部,附图标记30D为卡止结合装置50的缔结装置52、53的卡止部,插口管30还包括上述插口管本体部30A及卡止部30D。所述插口管30可以是金属或非金属,以利用模具成型的方式制造,因此,插口管本体部30A、管连接部30B、管接续部30C及卡止部30D以一体形成。

[0067] 插口管本体部30A形成为具有管结构,因此具有内周。管连接部30B设...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com