Assembly type steel structure framework supporting system and installation method

A steel structure frame and support system technology, applied in building construction, construction, etc., can solve the problems of unstable support system structure, high risk of work, unfavorable long-term use, etc., to improve installation efficiency and use convenience, The effect of increasing the placement area and facilitating disassembly and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

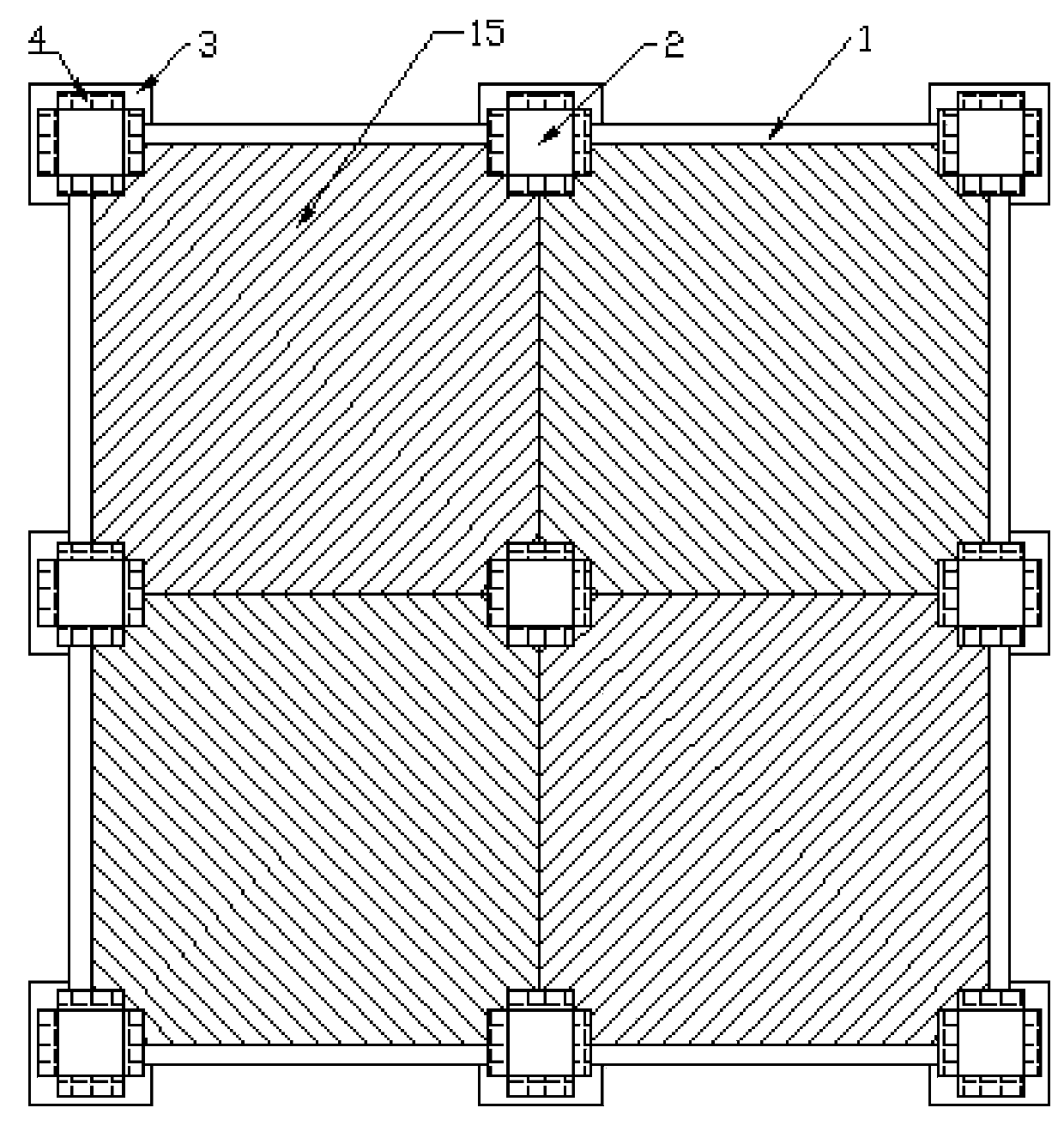

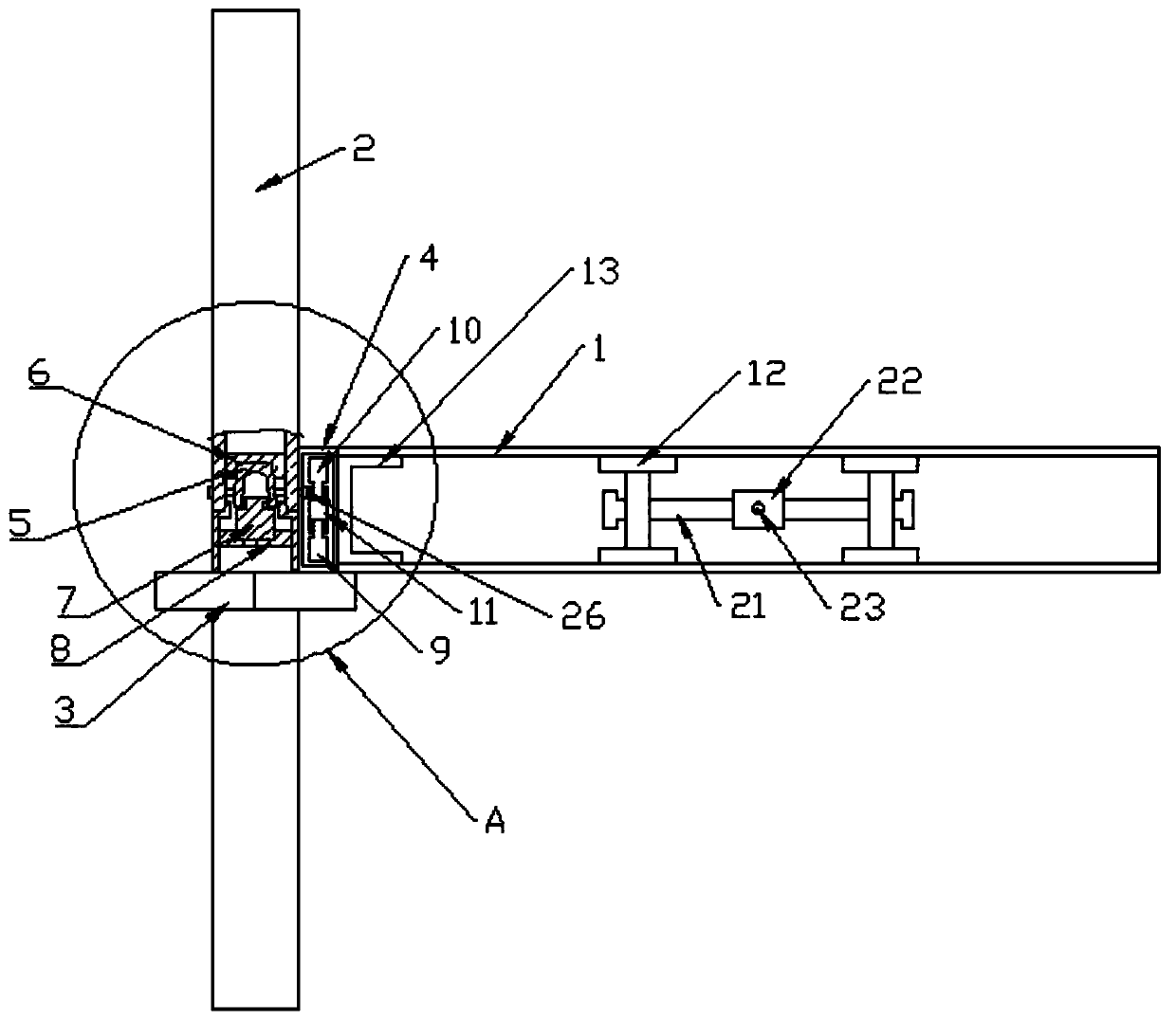

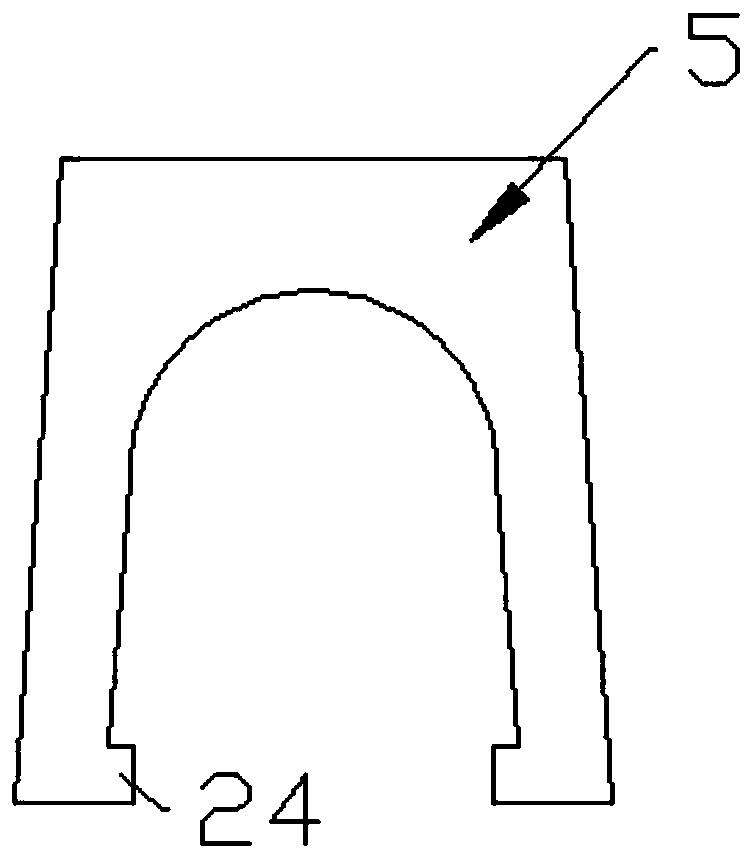

[0034] Such as Figure 1-Figure 9 As shown, the prefabricated steel frame support system provided in this embodiment includes a column 2 and an assembly beam 1, and one end of the column 2 is provided with an outer cover rod 6, and the outer cover rod 6 is clamped with a locking outer cover 5, and the locking outer cover 5 Both sides are provided with locking bolts 26, the other end of the column 2 is provided with a locking buckle connecting rod 8, and the locking buckle connecting rod 8 is clamped with a deadlocking buckle 7, and the outer side of the column 2 is provided with an auxiliary fastening block 4, and the auxiliary fastening block 4 The beam reinforcem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com