Sinker device for flat knitting machine head, flat knitting machine head and flat knitting machine

A technology of flat knitting knitting machine and machine head, which is applied in the directions of knitting, weft knitting, textile and paper making, etc., can solve the problems of incomplete knitting, damaged knitted fabric, insufficient working width of sinkers, etc., so as to improve the knitting effect, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

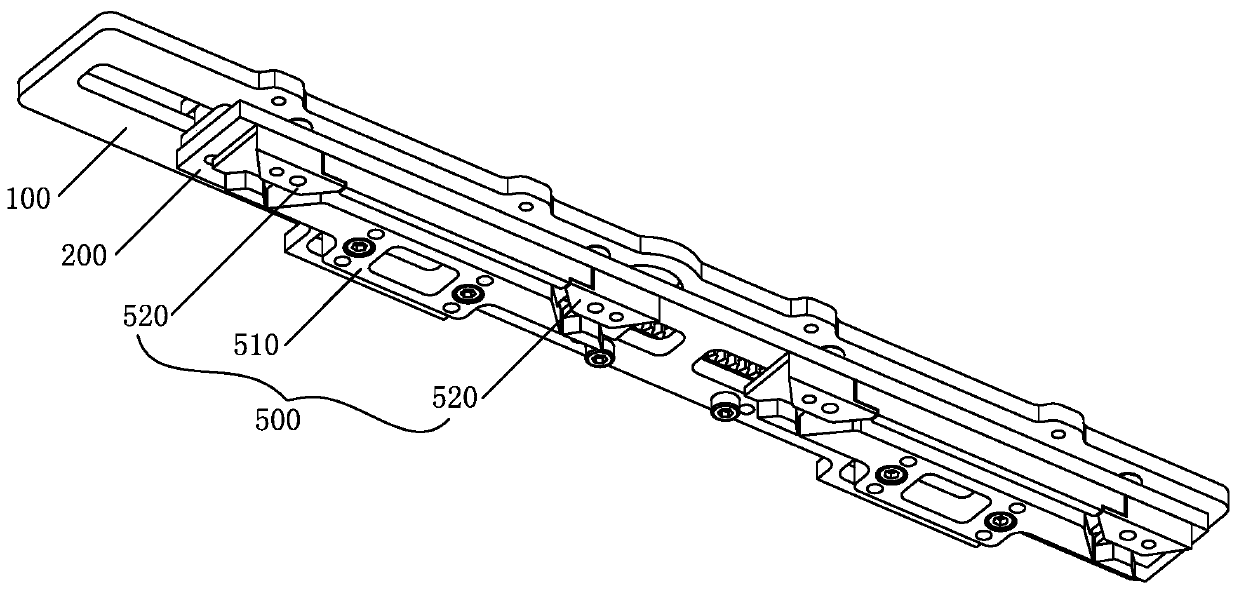

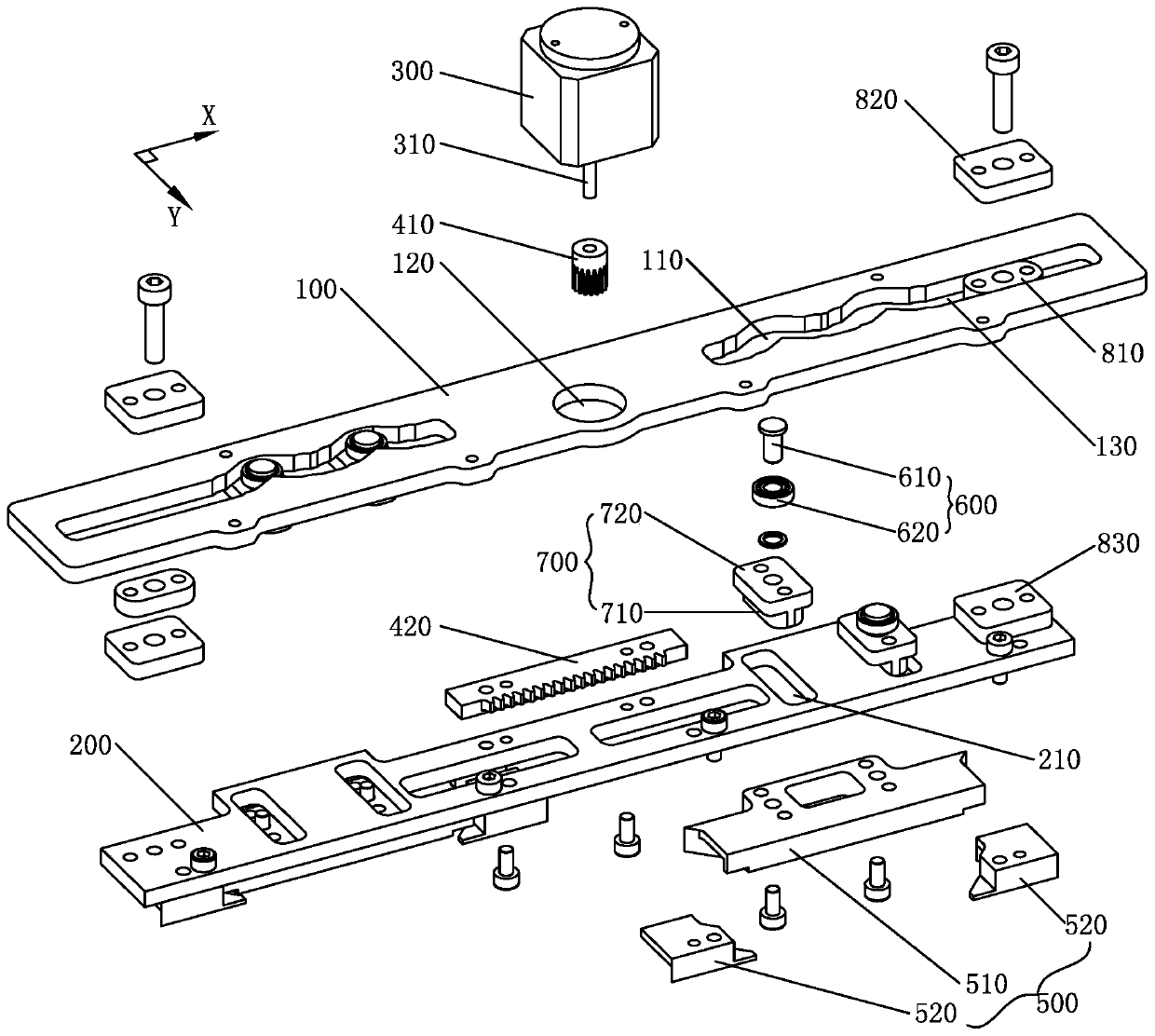

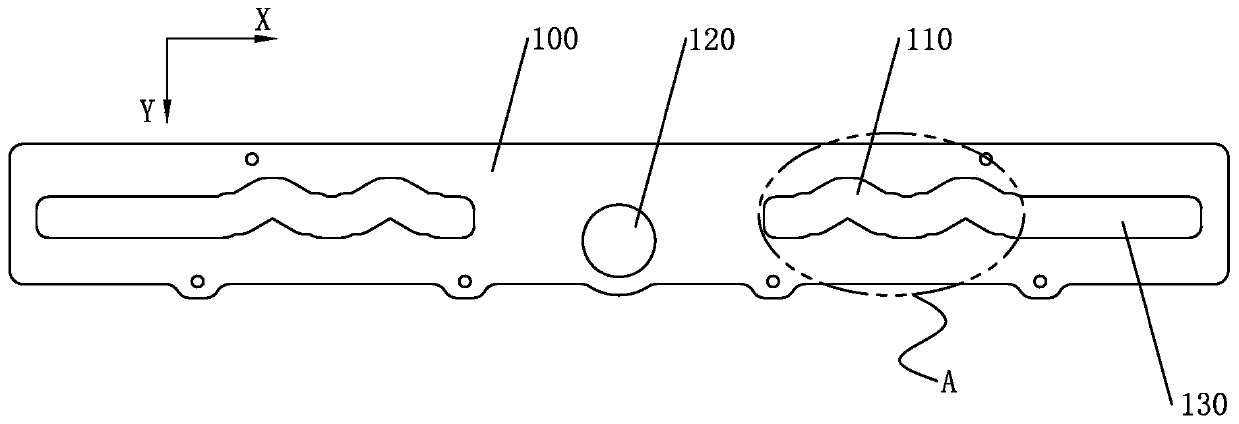

[0032] Such as figure 1 , figure 2 , image 3As shown, the Sink device of the flat knitting machine head provided by Embodiment 1 of the present invention includes a bottom plate 100, a slide bar 200, a motor 300, a transmission structure and at least one set of Sink triangle groups 500, and the slide bar 200 is arranged on the bottom plate 100 and can move back and forth laterally relative to the bottom plate 100. The Singer triangle group 500 is arranged on the bottom surface of the slide bar 200, and each group of Singer triangle group 500 includes a pusher triangle 510 and a return triangle 520, and the return triangle 520 is provided with two One and two restoring triangles 520 are symmetrically arranged at both lateral ends of the pushing triangle 510, and the transmission structure is arranged between the motor 300 and the slide bar 200. When the motor 300 works, the drive structure drives the slide bar 200 to move back and forth in the lateral direction to realize th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com