Magnesium-iron-calcium complexing compound flux for puddling and sintering ore

A technology for sintering ore and sintering agent, applied in the field of metallurgical flux, can solve the problems of difficulty in realizing thick material layer and low-temperature sintering, low lime milk bonding performance, poor gas permeability of the sintering material layer, etc., and achieves good fluidity of slag and iron. , Improve the sintering speed and output, the effect of less powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

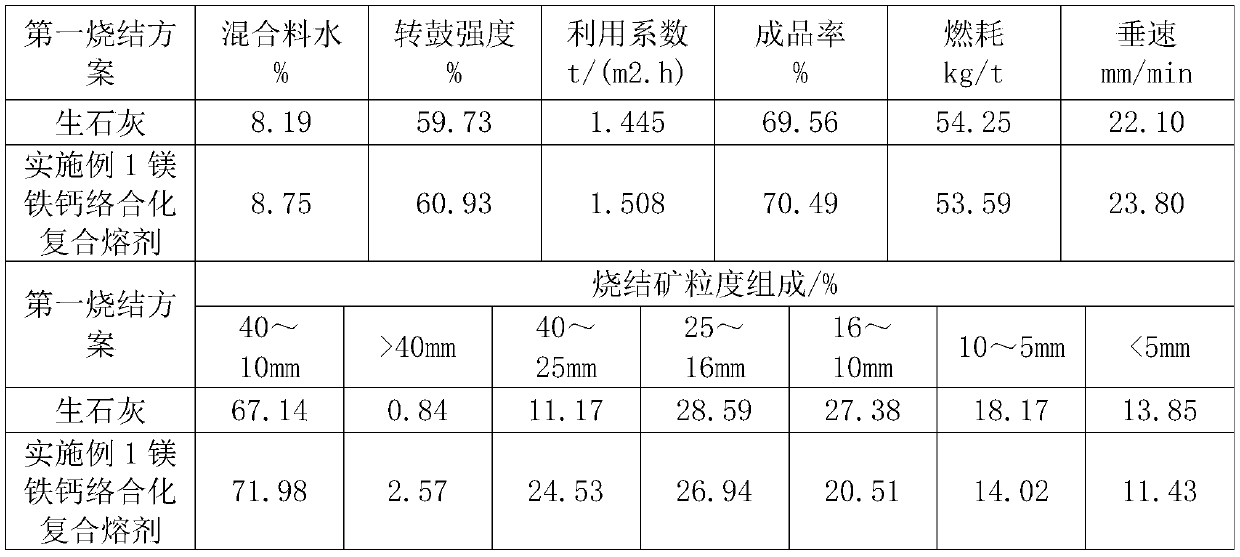

Examples

Embodiment 1

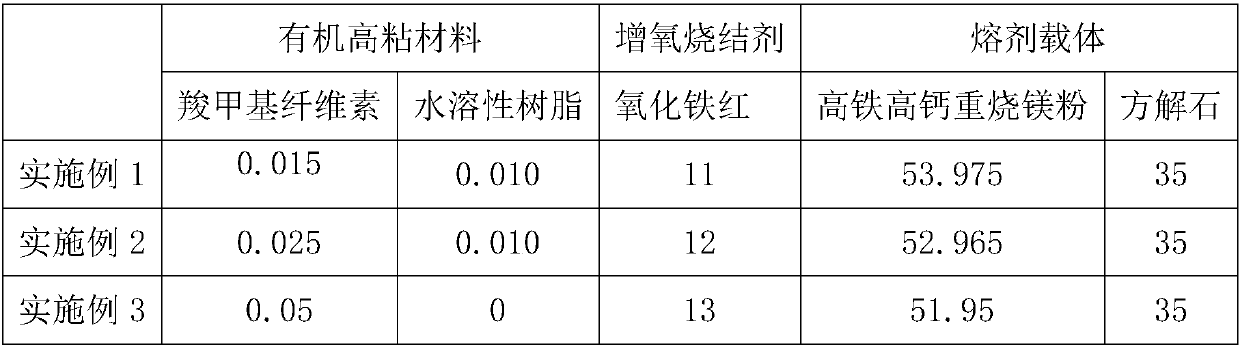

[0035] See Table 4 for the particle size composition of the sintered mixture in the first sintering scheme compared with Example 1;

[0036] Table 4: The first sintering plan sintering mixture particle size composition / %

[0037]

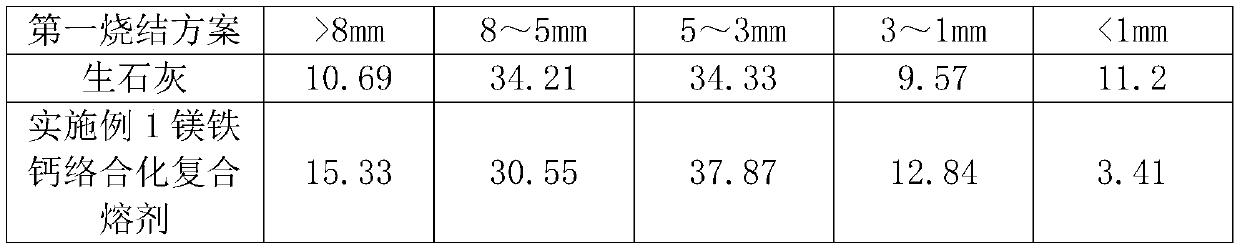

[0038] The performance indicators of the sintered ore of the first sintering plan are shown in Table 5;

[0039] Table 5: Performance indicators of sintered ore in the first sintering plan

[0040]

[0041] See Table 6 for the chemical composition indicators of the sinter in the first sintering plan;

[0042] Table 6: Chemical composition index of sinter in the first sintering plan

[0043]

Embodiment 2

[0044] The particle size composition of the sintered mixture in the second sintering scheme compared with Example 2 is shown in Table 7;

[0045] Table 7: The second sintering plan sintering mixture particle size composition / %

[0046]

[0047] The second sintering plan sinter performance index is shown in Table 8;

[0048] Table 8: Performance indicators of the second sintering plan sinter

[0049]

[0050]

[0051] See Table 9 for the chemical composition index of the sinter in the second sintering plan;

[0052] Table 9: The second sintering plan sinter chemical composition index

[0053]

Embodiment 3

[0054] See Table 10 for the particle size composition of the sintered mixture in the third sintering scheme compared with Example 3;

[0055] Table 10: The third sintering plan sintering mixture particle size composition / %

[0056]

[0057] The third sintering plan sinter performance index is shown in Table 11;

[0058] Table 11: Performance indicators of sintered ore in the third sintering plan

[0059]

[0060]

[0061] See Table 12 for the chemical composition index of the sinter in the third sintering plan;

[0062] Table 12: The third sintering plan sinter chemical composition index

[0063]

[0064] in conclusion:

[0065] 1. The average particle size of the sintered mixture with the addition of magnesium, iron and calcium complex compound flux becomes larger, and the part less than 1 mm is reduced. The sintered mixture particle size of less than 1mm accounts for ≤ 4%, which is conducive to the improvement of sintering gas permeability and the increase of vertical speed. .

[0066]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com