Piping for tank assemblies and tank assemblies for vehicles

A component and pipeline technology, which is applied in the field of plastic pipelines and vehicle tank components, can solve the problems of impossible to achieve reliable attachment of return pipelines, connection damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

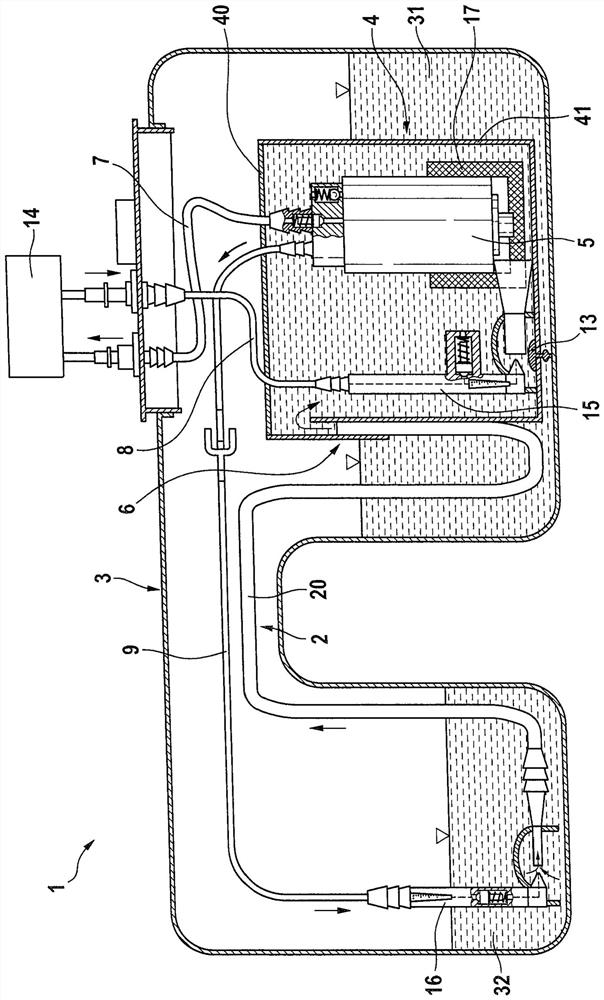

[0028] Refer below Figures 1 to 9 The box assembly 1 according to a preferred embodiment of the present invention is explained in detail.

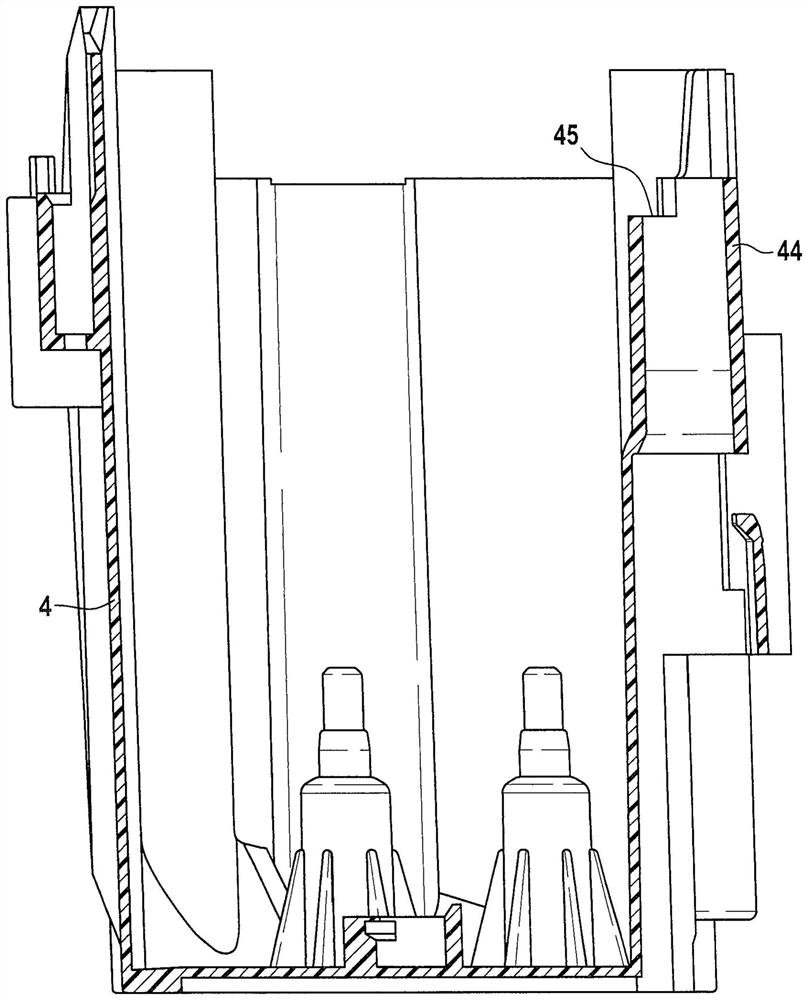

[0029] The tank assembly 1 comprises a tank 3 in the form of a saddle tank having a first tank chamber 31 and a second tank chamber 32 which are interconnected. In the first tank chamber 31 is arranged a storage tank 4 in which a pump 5 is installed. The storage tank 4 comprises a tank-shaped base body 41 which is closed by means of a lid 40 .

[0030] The storage tank 4 is filled with fuel from the first tank chamber 31 via the filling valve 13 . A first line in the form of a delivery line 7 leads from the pump 5 in order to deliver fuel to the internal combustion engine 14 . Fuel not consumed in the internal combustion engine is led back into the storage tank 4 via the return line 8 . In this case, the return line 8 leads to a first suction jet pump 15 which conducts the fuel to the pump 5 via a filter 17 .

[0031] Arranged in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com