Leakless safety valve

A safety valve and no-leakage technology, applied in the field of safety valves, can solve the problems of large leakage, difficult non-nuclear systems, high cost, etc., and achieve the effects of long working life, good working performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

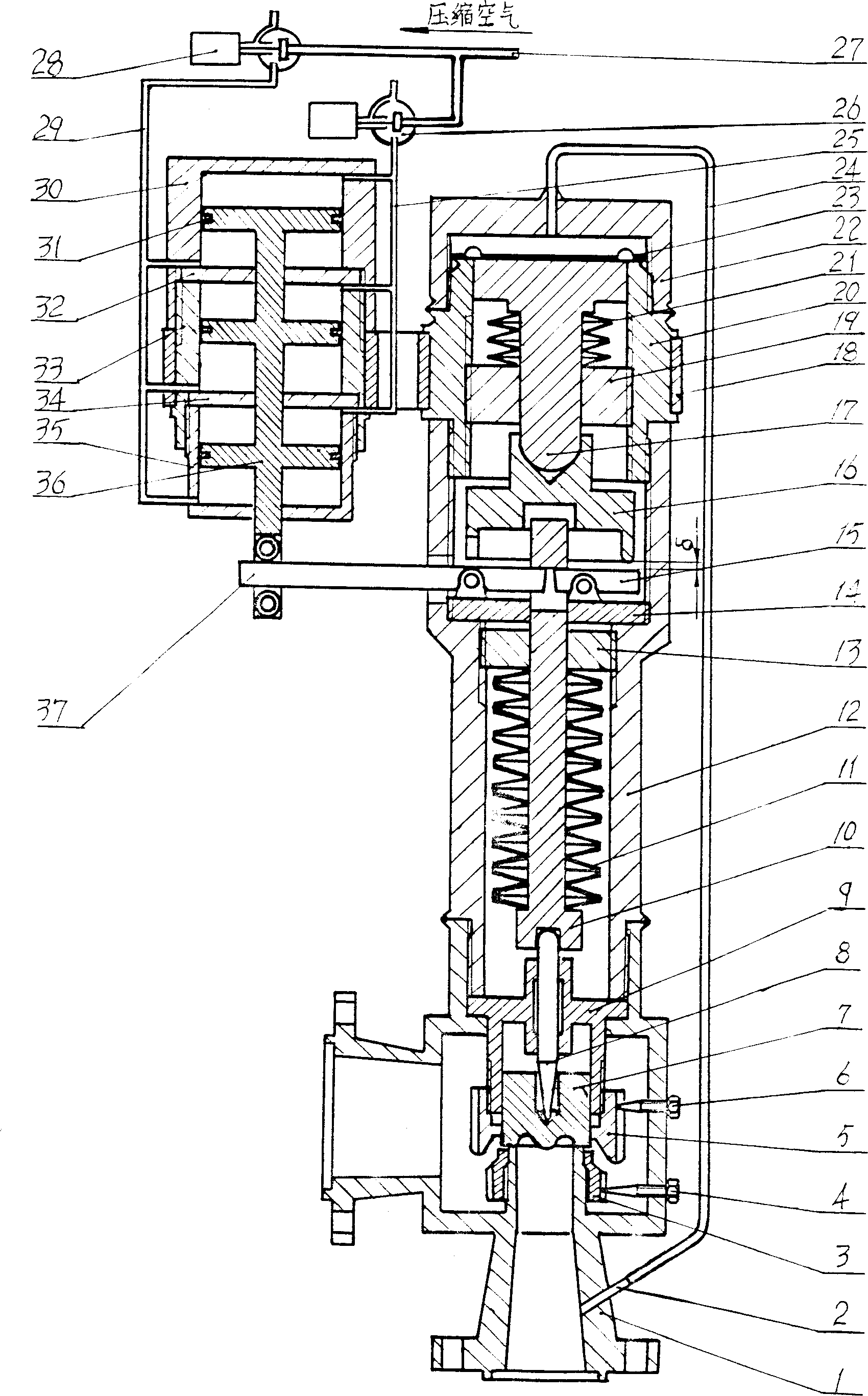

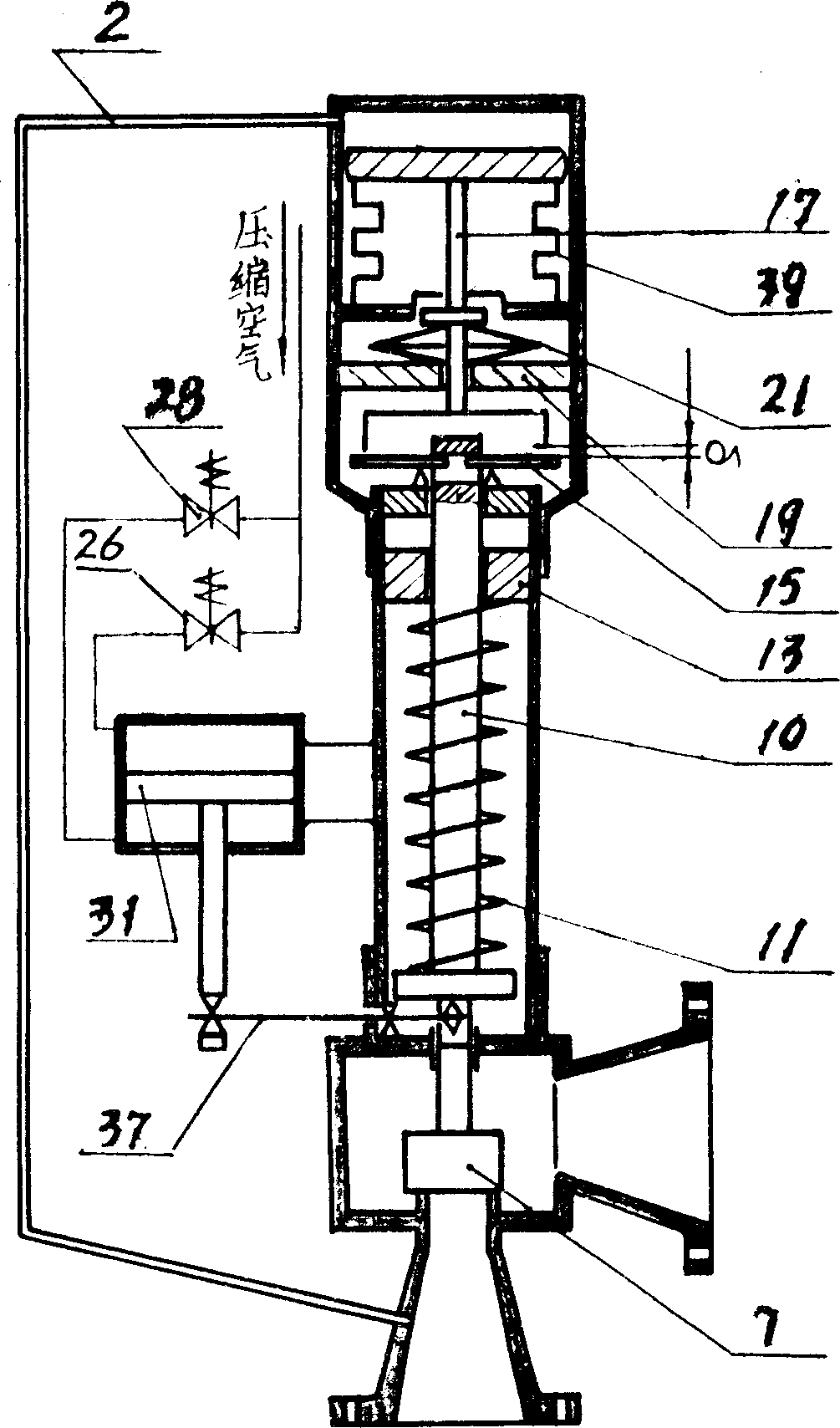

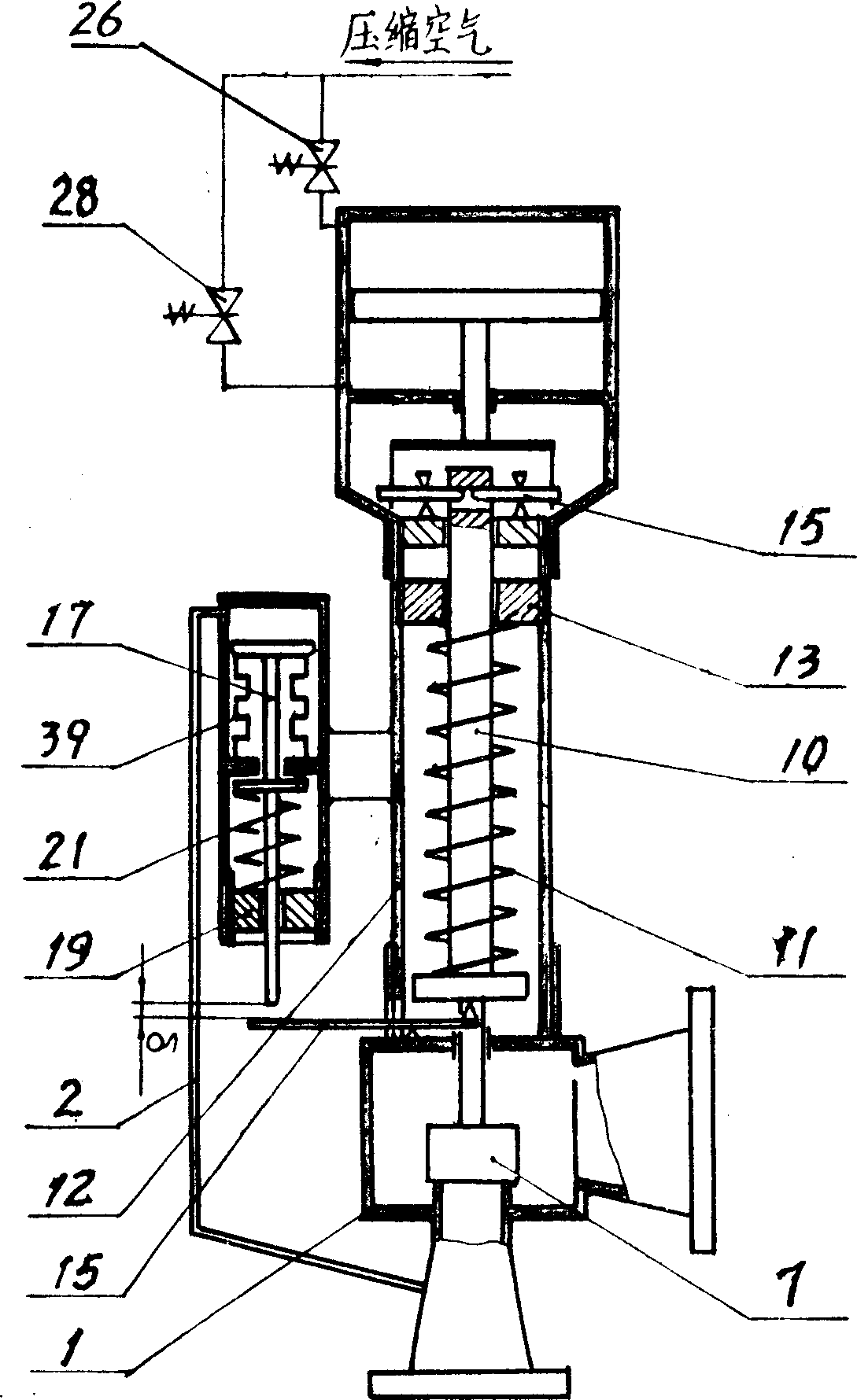

[0019] The new non-leakage safety valve consists of a safety function, a release function and a forced closing function. The safety function consists of the valve body with its internal spring loaded system and detonation system. The release function and the positive closing function are realized by a pneumatic piston device and a spring-loaded system.

[0020] Such as figure 1 As shown, the valve seat is integrated with the valve body (1), and the lower pressure plate (3) is screwed on the valve seat in a threaded manner, and the lower pressure plate (3) can be rotated to change its upper and lower positions and fix it. Screw (4) is used to prevent it from rotating, and valve disc (7) is placed in the guide cylinder (9). Screw the up-regulating pressure plate (5) on the outside of the guide cylinder (9) in a threaded connection, and rotate the up-regulating pressure plate (5) to change its upper and lower positions. The fixing screw (6) is used to prevent its rotation. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com