Circuit topology and control method of a high-power charging and discharging system

A charge-discharge, high-power technology, applied in the field of charge-discharge system circuit topology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

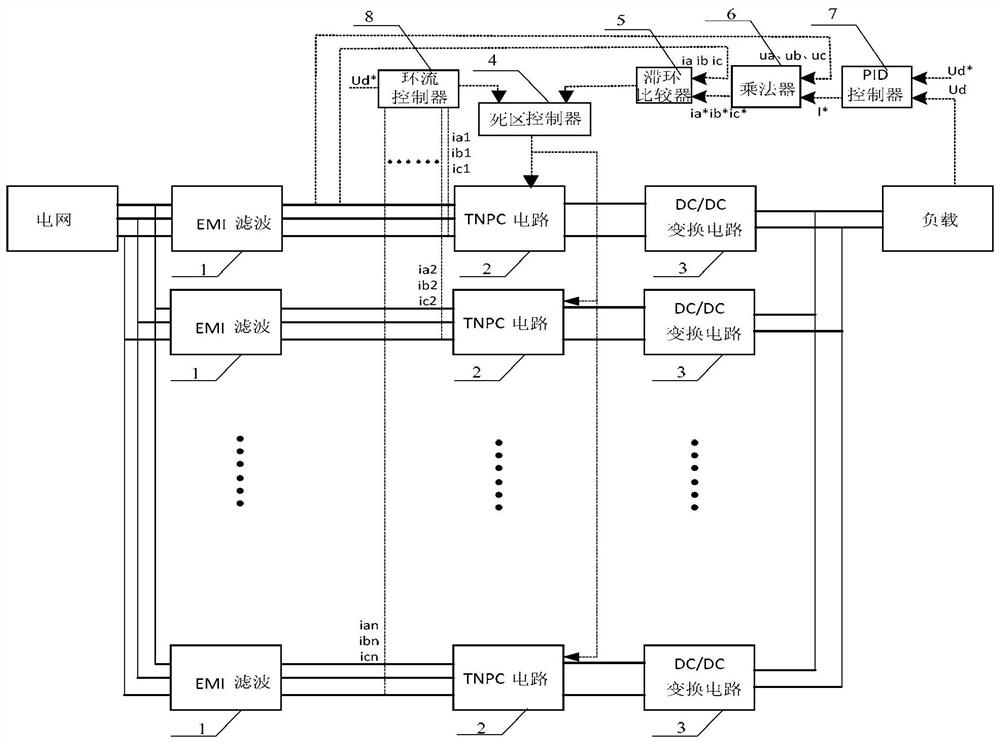

[0027] Specific implementation mode 1: the following combination figure 1 To explain this embodiment, the circuit topology of a high-power charging and discharging system described in this embodiment includes n EMI filter circuits 1, n TNPC circuits 2, n DC / DC conversion circuits 3, and dead zone controller 4 , Hysteresis comparator 5, multiplier 6, PID controller 7 and circulating current controller 8;

[0028] An EMI filter circuit 1 is connected in series with a TNPC circuit 2 and a DC / DC conversion circuit 3 to form a set of converter circuits, and n groups of converter circuits are connected in series between the power grid and the load in parallel;

[0029] The voltage signal input terminal of the circulating current controller 8 inputs the preset DC voltage Ud * ; 0-t time, the circulating current controller 8 simultaneously inputs the feedforward control signal to the control signal input end of the TNPC circuit 2 of each group of converter circuits;

[0030] After time t, st...

specific Embodiment approach 2

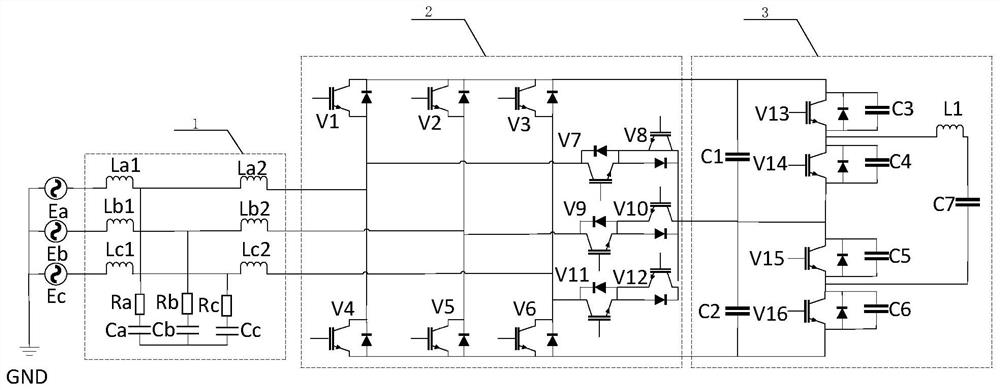

[0036] Specific implementation manner 2: the following combination figure 2 To illustrate this embodiment, this embodiment further explains the circuit topology of a high-power charging and discharging system described in the first embodiment, and also includes a dead zone controller 4 whose signal input terminal is connected to the circulating current The feedforward signal output terminal of the controller 8 and the signal output terminal of the hysteresis comparator 5.

specific Embodiment approach 3

[0037] Specific implementation manner three: the following combination figure 2 To explain this embodiment, this embodiment further explains the circuit topology of a high-power charging and discharging system described in Embodiment 1 or 2. The EMI filter circuit 1 includes a resistor Ra, a resistor Rb, a resistor Rc, a capacitor Ca, and a capacitor Cb. , Capacitor Cc, inductor La1, inductor La2, inductor Lb1, inductor Lb2, inductor Lc1, and inductor Lc2;

[0038] One end of the inductor La1 is connected to the a-phase power output terminal of the AC power supply, the other end of the inductor La1 is connected to one end of the resistor Ra and one end of the inductor La2 at the same time, and the other end of the resistor Ra is connected to one end of the capacitor Ca;

[0039] One end of the inductor Lb1 is connected to the b-phase power output end of the AC power source, the other end of the inductor Lb1 is connected to one end of the resistor Rb and one end of the inductor Lb2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com