Vehicle leaf spring unit gap detecting system

A detection system and unit chip technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of not being able to guarantee the bonding state of the reed, affecting the assembly effect, and high labor intensity, and achieve simple structure, low labor intensity, and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the purpose of the present invention and the advantages of the technical solution more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

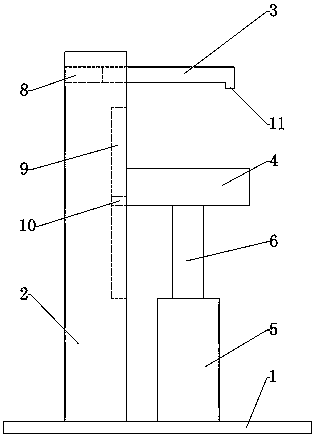

[0016] as attached figure 1 As shown, a vehicle leaf spring unit plate gap detection system is characterized in that it includes a base 1, a column 2 is vertically arranged on the base 1, and an upper fixing block 3 is provided on the top of the column 2. A movable block 4 is provided directly below the fixed block 3, and the bottom of the movable block 4 is connected with the piston rod 6 of the cylinder 5 on the installed base 1 and moves vertically to and fro under the push of the cylinder 5. The cylinder 5 is connected with the air supply device, and the leaf spring 7 is clamped between the fixed block 3 and the movable block 4.

[0017] A through hole 8 is provided on the top of the column 2 along the axial direction of the fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com