Method for shape-finding and constructing of air-rib-type ice shell building

A construction method and building technology, which are applied to building construction, construction, and on-site preparation of building components, etc., can solve the problems of slow inflation, high cost, and poor observation of airbags, shortening manufacturing time, and facilitating form finding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

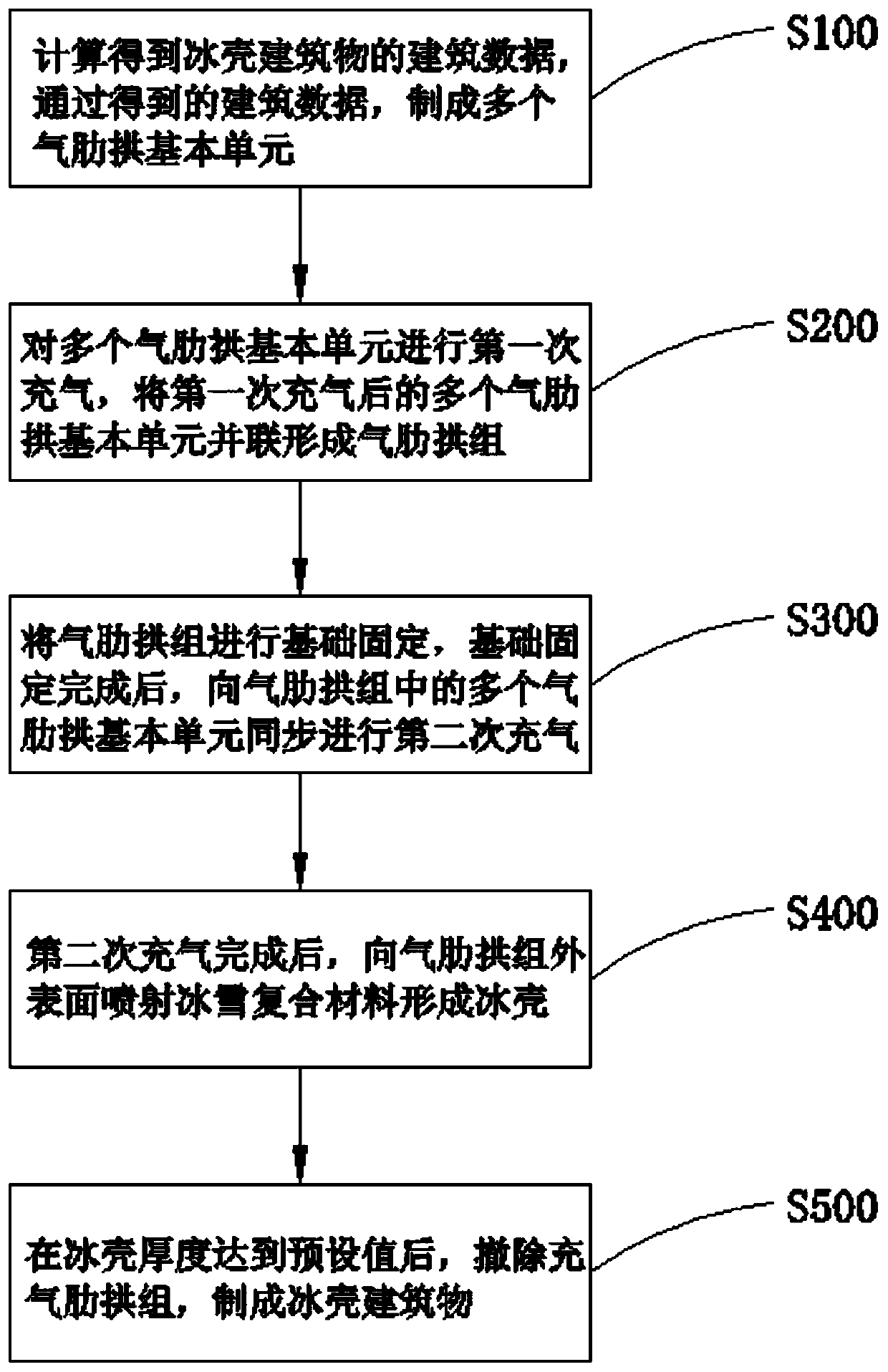

[0049] Such as figure 1 As shown, a form-finding and construction method of an air-ribbed ice shell building, comprising:

[0050] S101: Calculate and obtain the architectural data of the ice-shell building, and make a plurality of air-rib arch basic units through the obtained architectural data.

[0051] Specifically, before the ice shell building is manufactured, the air-rib arch basic unit needs to be made in advance, which is mainly based on the design intention of the ice shell building, and the simulation calculation is carried out through finite element analysis software (such as ABAQUS, ANSYS, MSC), so that The architectural data of the ice shell building is calculated, and the architectural data mainly include the overall shape and size of the ice shell building, the number of air-rib arch basic units, the size of a single air-rib arch basic unit, and the interior of a single air-rib arch basic unit Air pressure withstands dangerous values, etc.

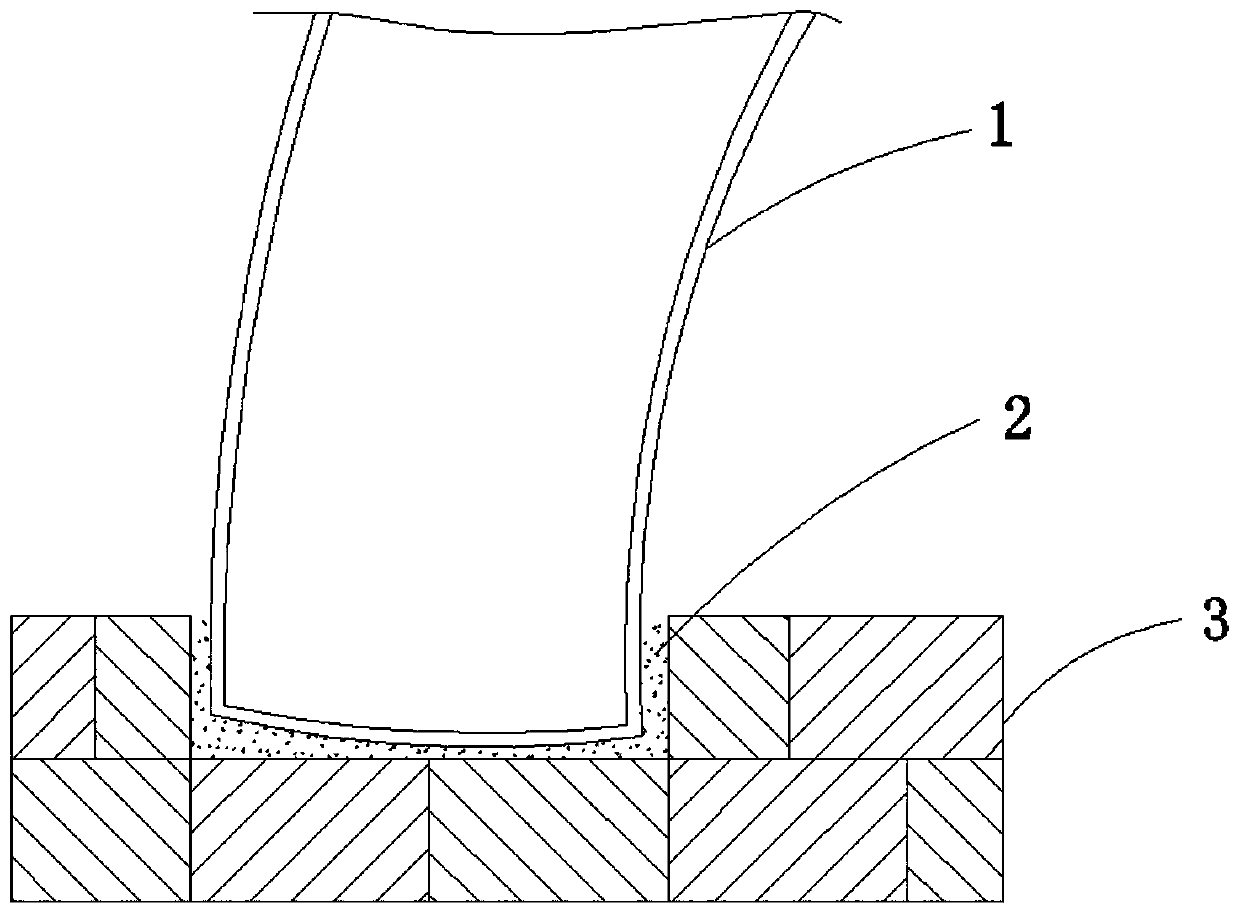

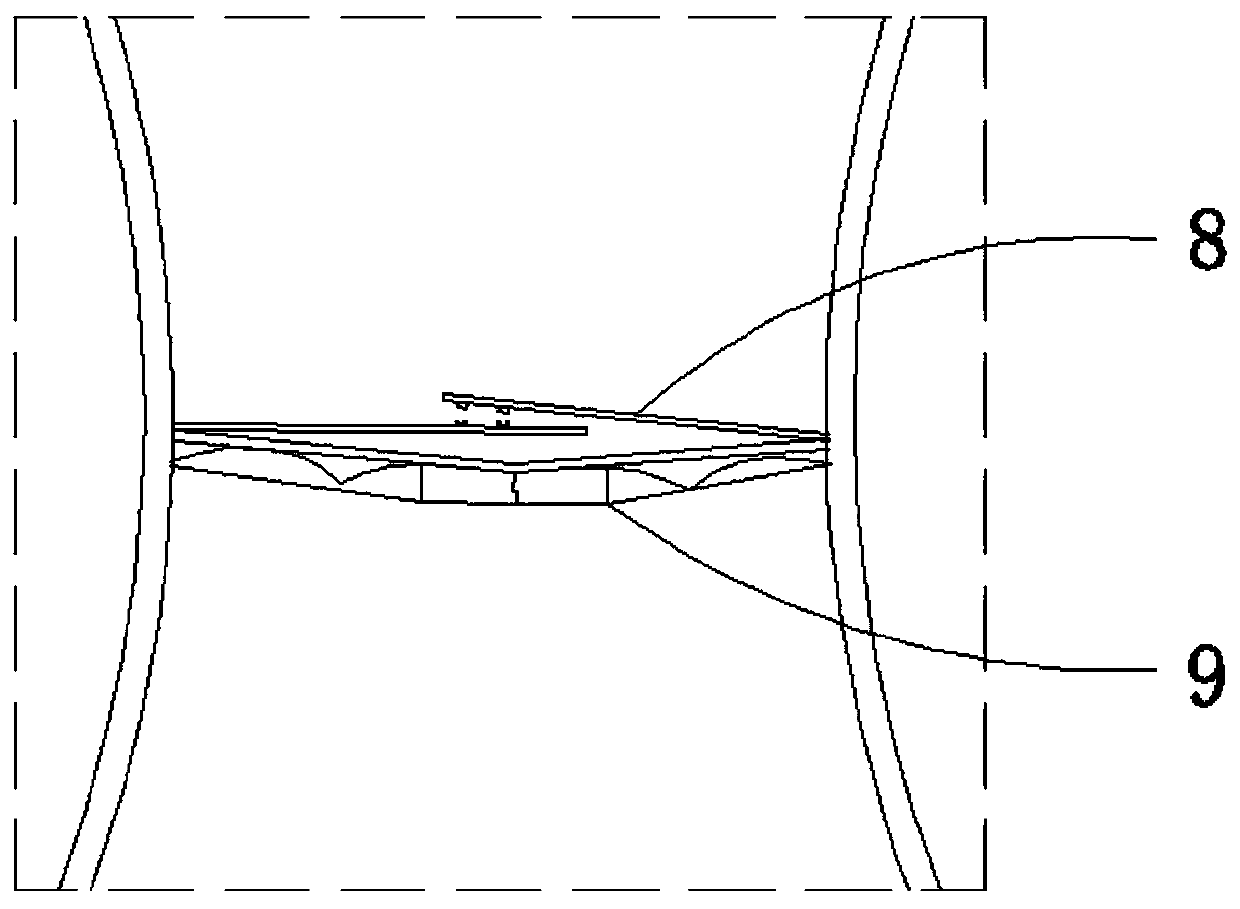

[0052] After calcu...

Embodiment 2

[0078] Compared with the above embodiment, in this embodiment, after the thickness of the ice shell reaches the preset value, it is judged whether the number of the ice shell needs to be increased; if the number of the ice shell does not need to be increased, the air rib arch group is removed to make the ice shell Buildings; if the number of ice shells needs to be increased, remove the air-rib arch group and complete the first construction; then use the air-rib arch group for the first construction as a unit mold, based on the ice shell obtained in the first construction, Use at least one method of juxtaposition, rotation, and symmetry for form-finding and construction until it is no longer necessary to add ice shells, remove air rib arch groups, and finally make ice shell buildings. The use of air-rib arch groups for wheel construction can effectively save the materials used to make the basic units of air-rib arches.

[0079] In this embodiment, the added ice shell is carried...

Embodiment 3

[0081] Compared with the above-mentioned embodiment, in this embodiment, after the removal of the air-rib arch group is completed, the internal space of the ice shell is constructed, which mainly includes internal ice engineering construction, ice sculpture carving, lamp arrangement, equipment connection, etc., so that the final Realize the production of ice shell buildings.

[0082] In this embodiment, when the number of ice shells needs to be increased, in the subsequent ice shell manufacturing process, construction can be carried out on the inner space of the ice shells that have already been made, so as to save the manufacturing time of the ice shell buildings as a whole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com