A kind of manufacturing method of white light LED element containing particle size gradient fluorescent glue

A gradient fluorescence and manufacturing method technology, applied in the direction of electrical components, semiconductor devices, circuits, etc., can solve the problems of difficult color temperature distribution of LED components, low lumen efficiency, and small material consumption, so as to achieve high-quality lighting experience and manufacturing The effect of low cost and uniform color temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

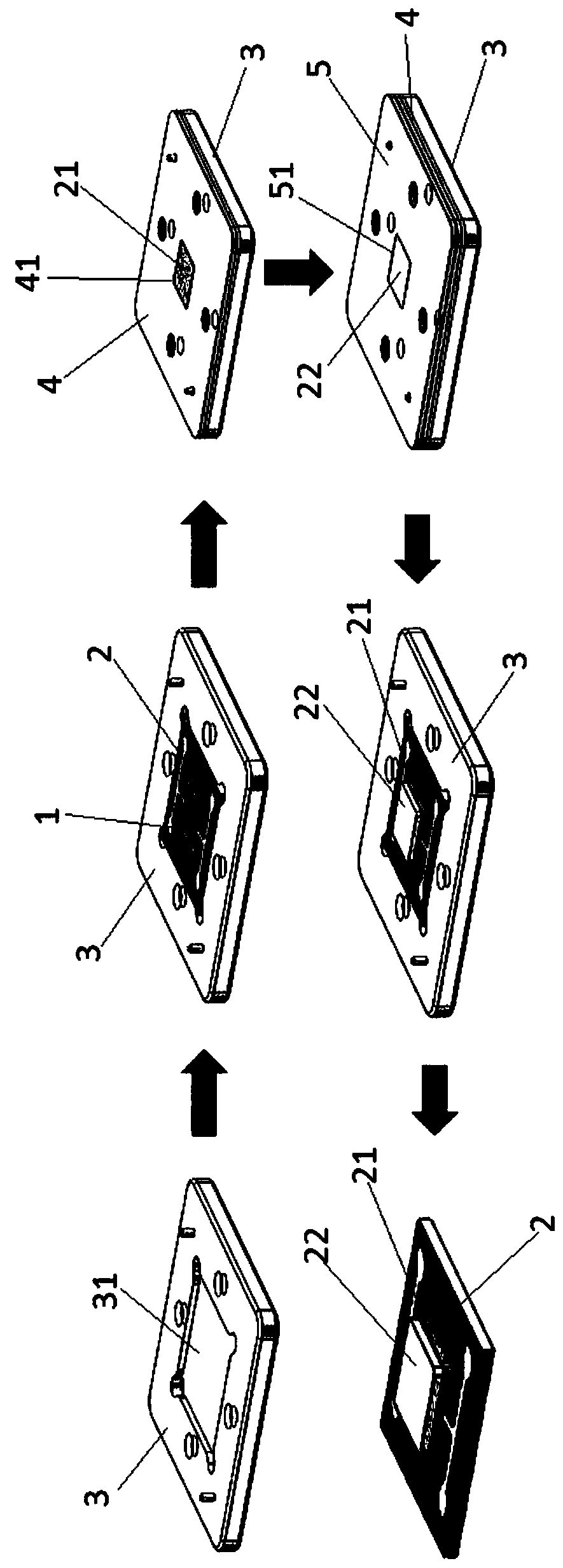

[0035] Such as Figure 1-3 As shown, this embodiment provides a method for manufacturing a white light LED element containing particle size gradient fluorescent glue, which specifically includes the following steps:

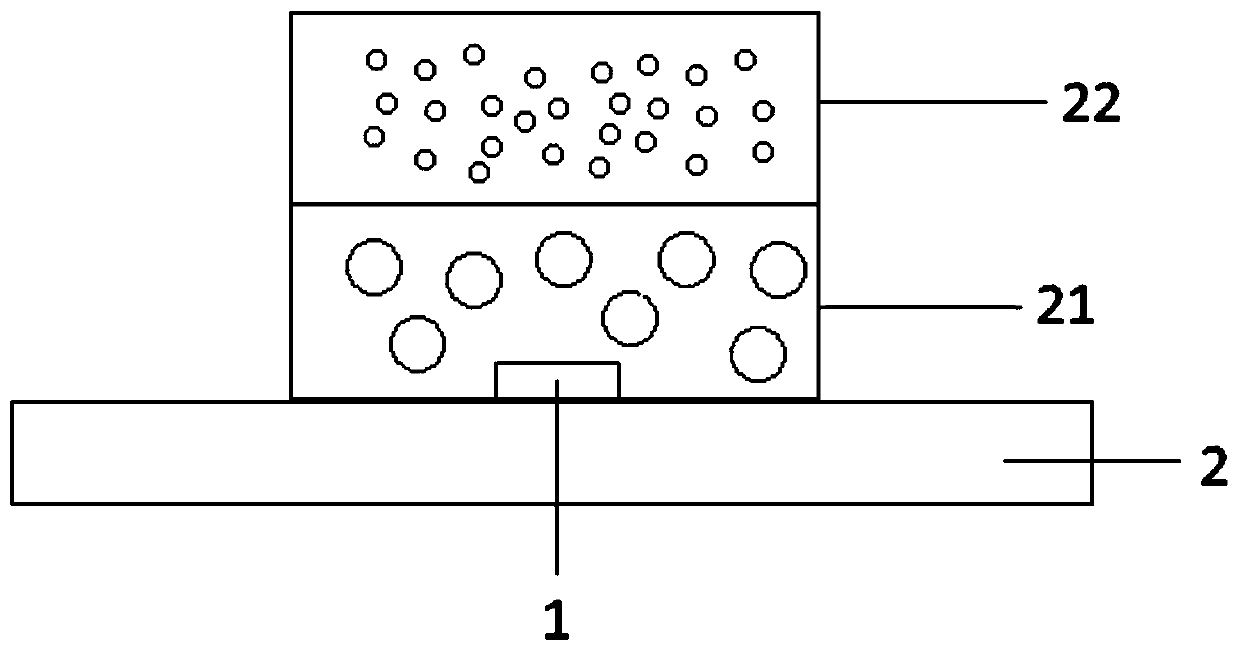

[0036] 0. Chip packaging: the blue LED chip 1 is packaged on the metal substrate 2 through a chip-on-board packaging process (CoB), which can realize multi-chip packaging, and has good heat dissipation and light output performance.

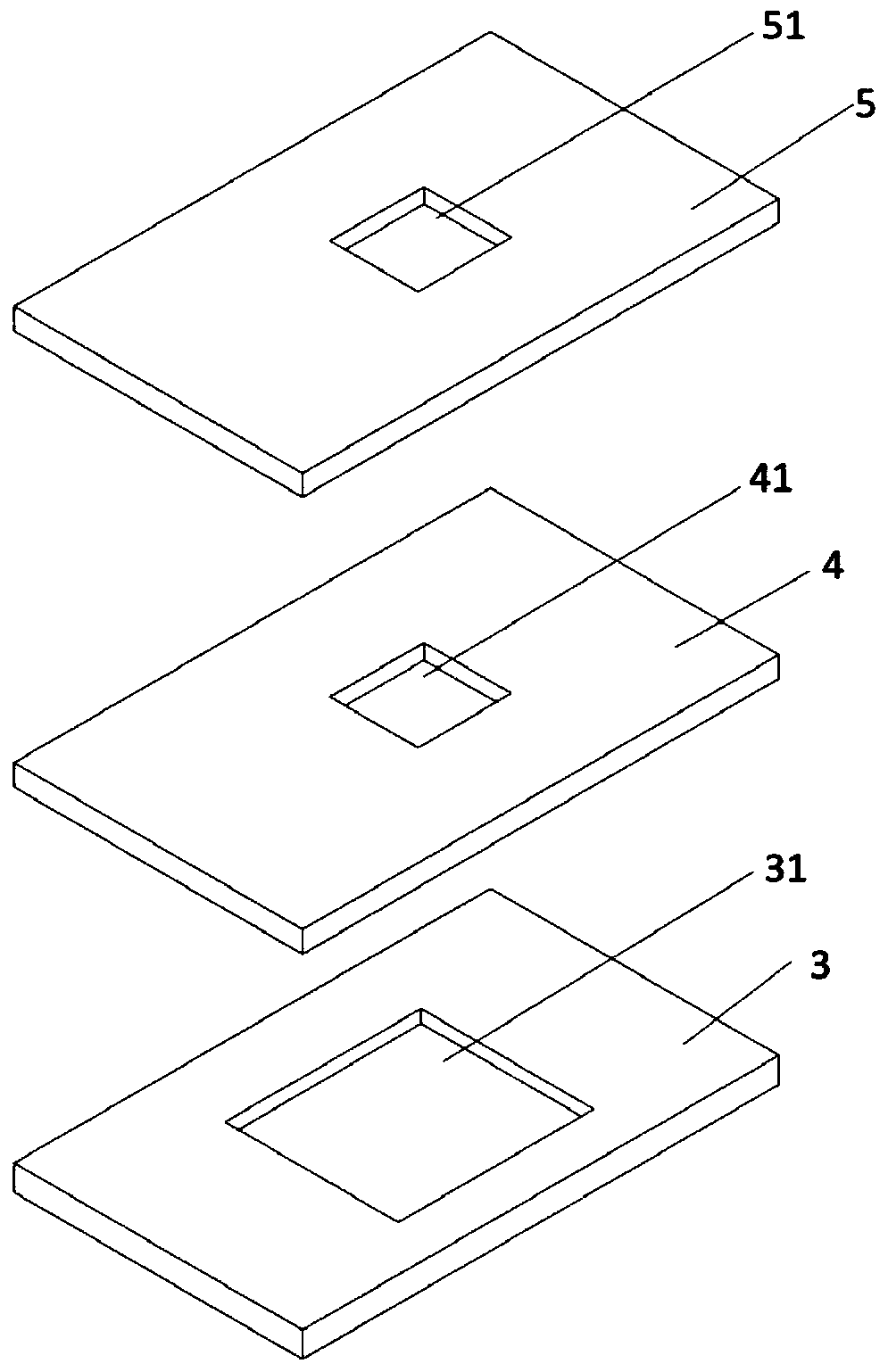

[0037] 1. Prepare the mould; prepare the mold substrate 3 for fixing the substrate, the first spacer 4 and the second spacer 5 for dispensing fluorescent glue, wherein, the middle part of the mold substrate 3 is provided with a groove 31 consistent with the size of the substrate, the second A first through hole 41 is formed in the middle of a gasket 4 , and a second through hole 51 is formed in the middle of the second gasket 5 . It should be noted that, in this process, the thickness of the first spacer 4 and the second spacer 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com