Modular multifunctional gas turbine test bench

A gas turbine and modular technology, applied in the field of test benches, can solve the problems of repeated construction of equipment and systems, and achieve the effects of high utilization rate, avoiding repeated construction, saving space requirements and equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

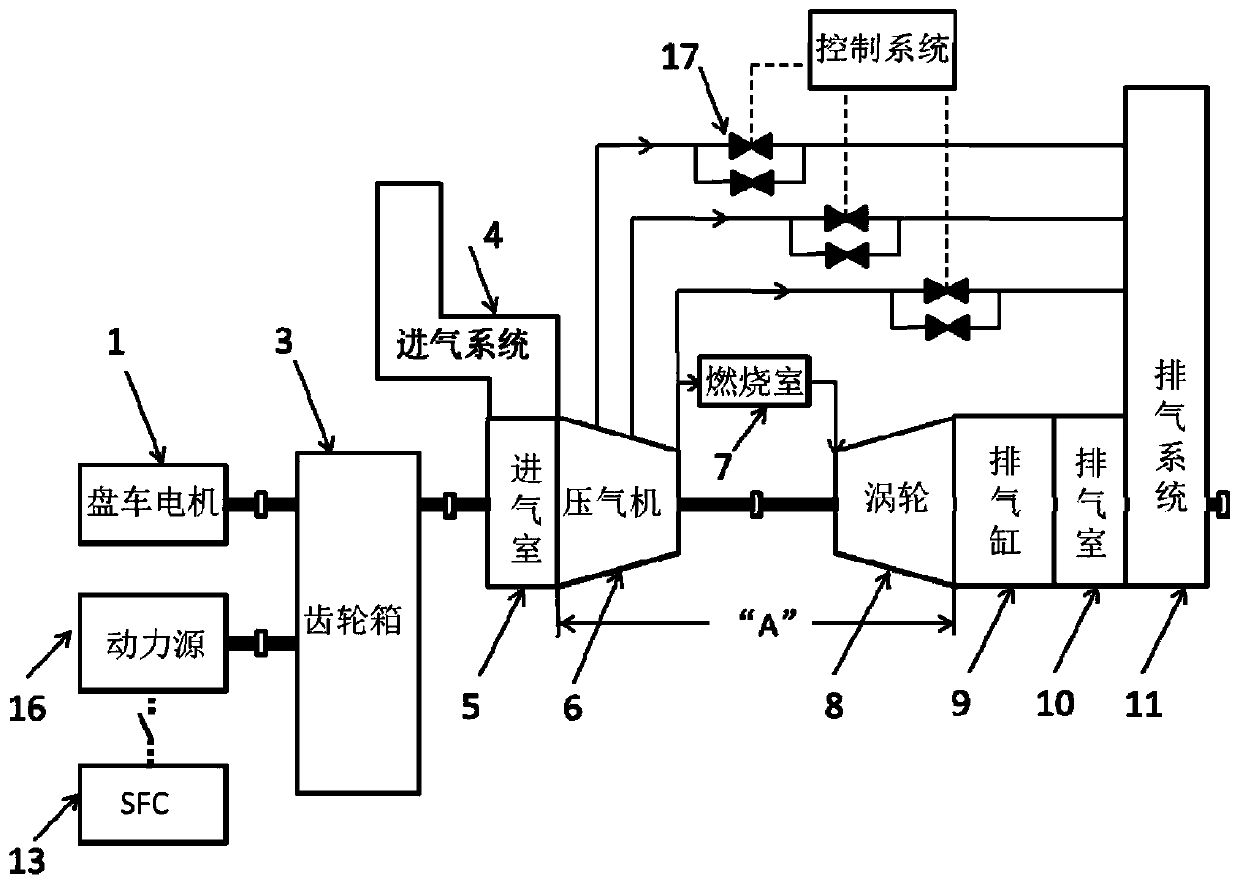

[0036] Such as Figure 1-7 As shown, a modular multi-function gas turbine test bench of this embodiment is provided with a compressor installation station and a turbine installation station, wherein the fixed shared equipment includes a gear box 3, a combustion chamber 7, and a compressor installation station. The intake system 4 and intake chamber 5 of the station, and the exhaust cylinder 9, exhaust chamber 10 and exhaust system 11 installed in the turbine installation station. Among them, the compressor installation station is used to install the test compressor 6, and the turbine installation station is used to install the turbine 8 to complete the corresponding test.

[0037] In this embodiment, the gearbox 3 includes at least one high-speed shaft and at least one low-speed shaft, wherein one end of the high-speed shaft is used for connecting the crank motor 1 , and the other end is used for connecting the test compressor 6 . The low-speed shaft on the gearbox 3 is used ...

Embodiment 2

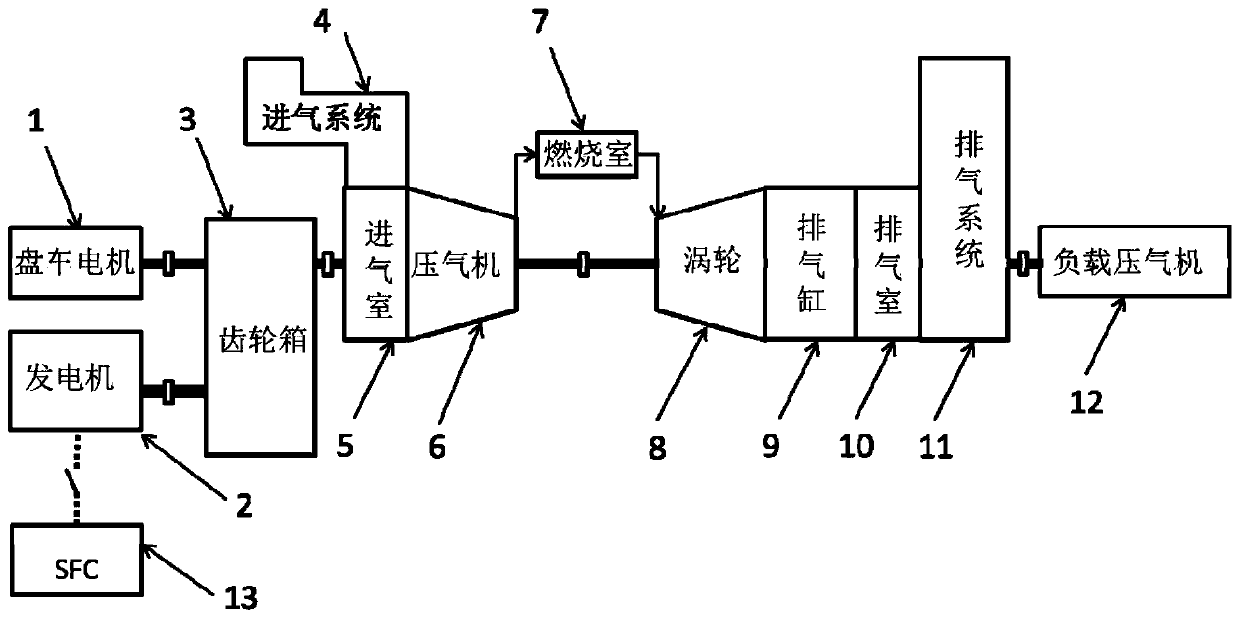

[0042] Such as figure 1 As shown, in this embodiment, the modularized multifunctional gas turbine test bench is used for the compressor test. In this test state, a test compressor 6 is installed at the compressor installation station, and an aerodynamic turbine 8 is installed at the turbine installation station. Among them, the test compressor is connected coaxially with the aerodynamic turbine, the test compressor is connected with the intake chamber, and the air intake system is provided by the air intake system; the aerodynamic turbine is connected with the exhaust cylinder, and the exhaust gas is discharged through the exhaust chamber and the exhaust system.

[0043] In this example, if Figure 9 As shown, the flange interface 25 of the combustion chamber is connected to the stuffy plate flange 28, and the function of the combustion chamber is only to introduce the compressed gas from the test compressor into the aerodynamic turbine, and has no combustion function.

[00...

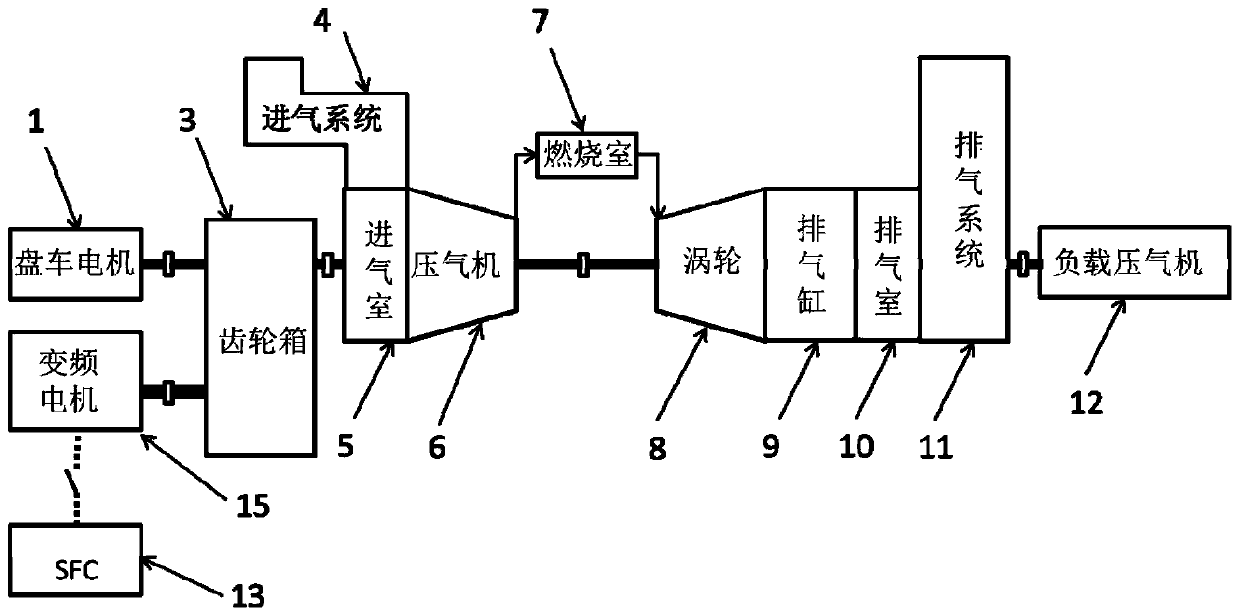

Embodiment 3

[0055] In this embodiment, the modularized multifunctional gas turbine test bench is used for the no-load test of the whole machine, which can be adjusted appropriately on the basis of the compressor test in the second embodiment. Specifically, as Figure 10 As shown, replace the blank flange connected to the flange interface of the combustion chamber with the fuel nozzle and the flame tube

[0056] A preferred embodiment, in the no-load test state of the complete gas turbine, the compressor installation station is equipped with a test compressor, and the turbine installation station is equipped with an aerodynamic turbine, and the test compressor and the aerodynamic turbine are installed at the same time. The flange interface of the combustion chamber is connected with a combustion assembly composed of a fuel nozzle 29 and a flame tube 30 . Wherein the fuel nozzle 29 and the flame tube 30 are connected with a fuel pipeline and a fuel system, and other equipment and component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com