Double-pole multi-degree-of-freedom drilling rig

A technology with a degree of freedom and a drilling rig, which is applied in drilling equipment, directional drilling, earthwork drilling, etc., can solve problems such as complex cooperation between chains and pulleys, affecting normal work, and not suitable for fine-tuning left and right, so as to improve drilling efficiency and adjust Precise positioning and obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

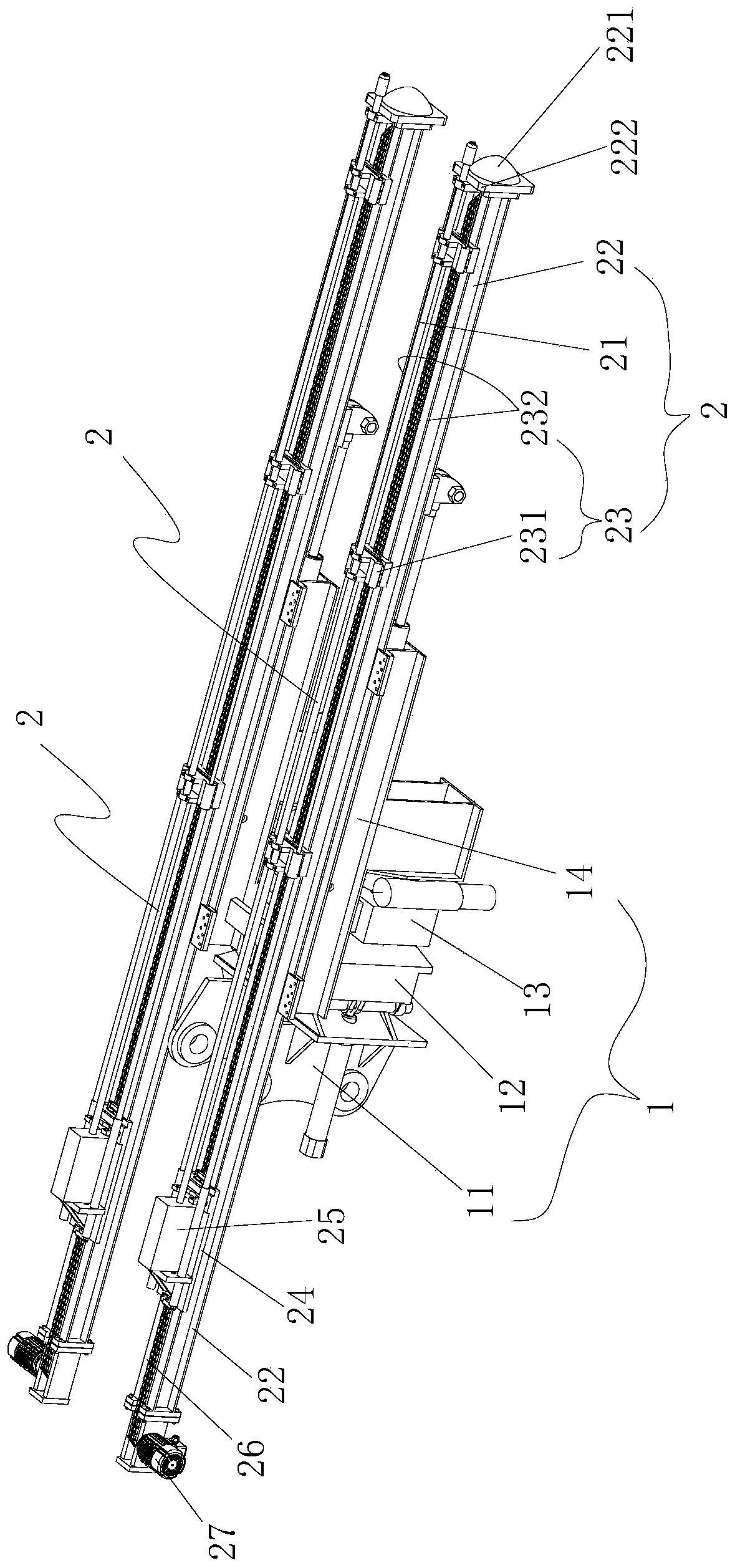

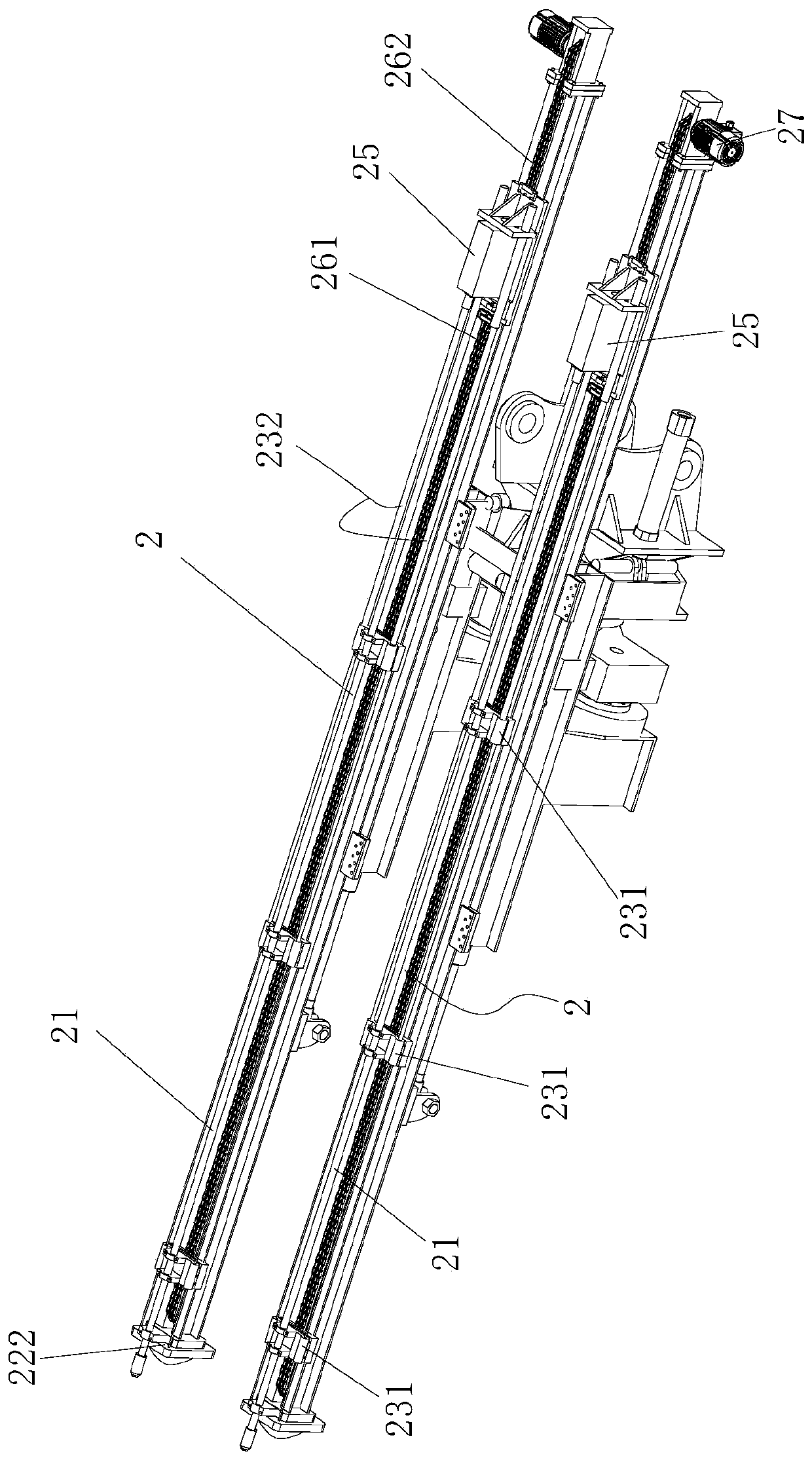

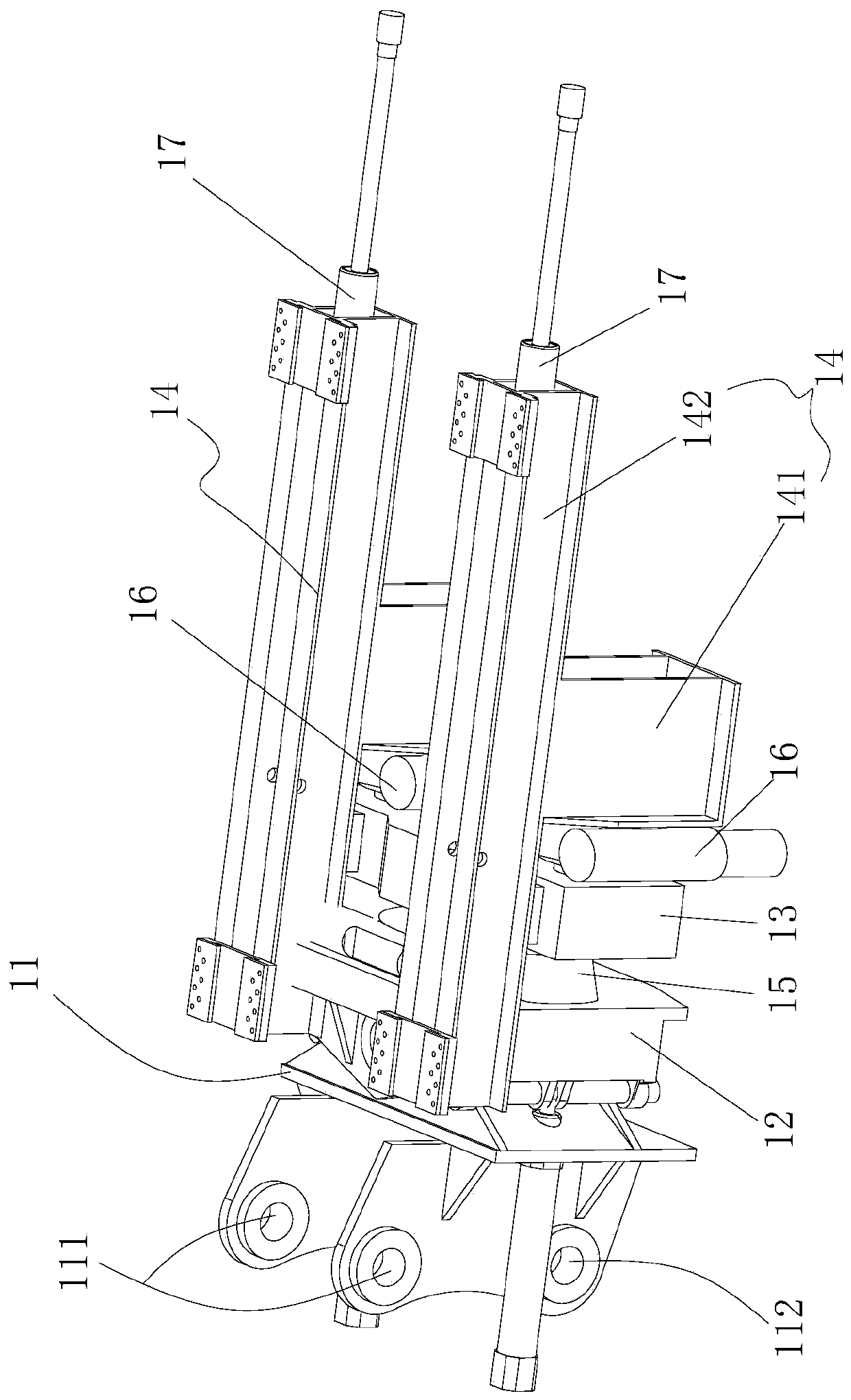

[0028] Example: see Figure 1 to Figure 3 , a double-rod excavation drilling rig with multiple degrees of freedom, including a base assembly 1 and a drill assembly, the base assembly 1 is provided with a drill assembly, and the base assembly 1 has more than two degrees of freedom adjustment; the drill assembly is It consists of two groups of drills 2, which are installed side by side on the seat assembly to form a double-rod structure. Each group of drills includes drill rods 21, sliding tables 22 and anti-deflection components 23. The sliding tables 22 are longitudinally extending support structures. The rod 21 is arranged on the slide table 22 and can slide back and forth in the longitudinal extension direction to realize the drilling operation. The anti-bias assembly 23 includes an anti-bias support 231 and a telescopic rod 232. The anti-bias support 231 is slidably arranged on the slide table 22 to prevent The partial support 231 is provided with a drill pipe hole to allow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com