Flexible high-strength connecting rib and assembly method thereof

A high-strength technology for connecting ribs, applied to building reinforcements, structural elements, building components, etc., can solve problems such as splicing difficulties and grouting difficulties, and achieve the goals of avoiding incomplete grouting, reliable connection, and strong pull-out resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below through specific embodiments.

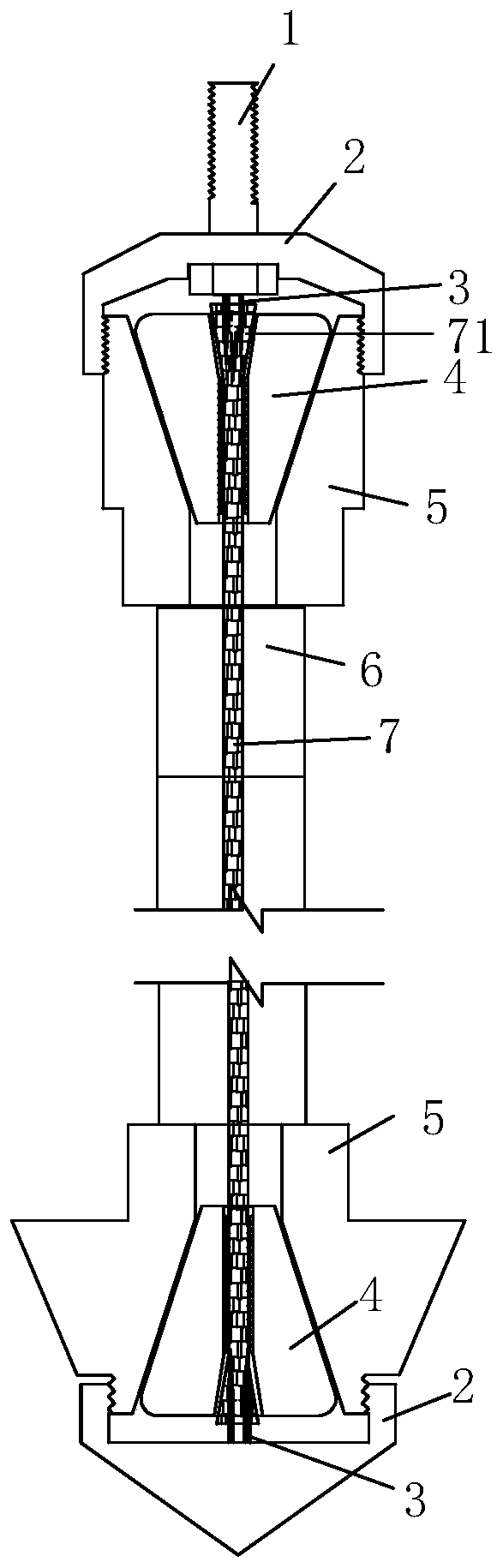

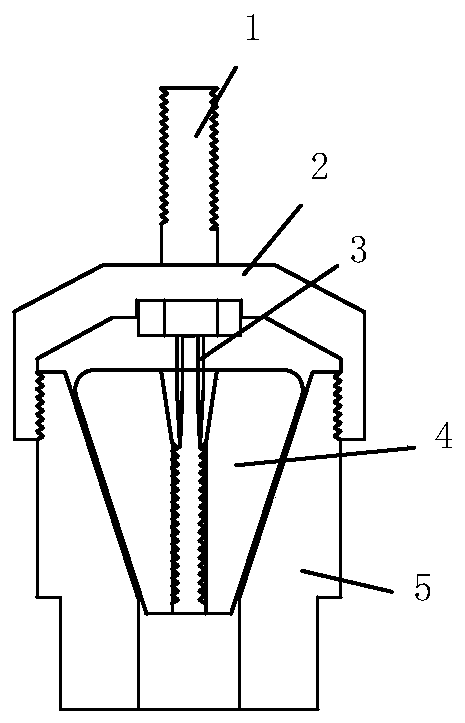

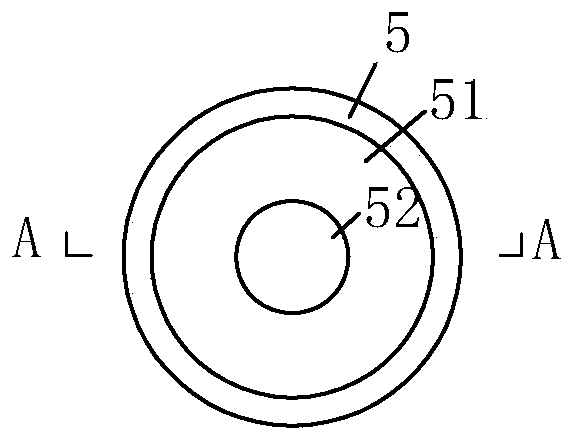

[0058] refer to Figure 1 to Figure 19 , a flexible high-strength connecting bar, including two anchor ends, a sleeve 6 and a steel cable 7 and so on. The anchoring end includes an anchor cap 2 , a constraint sleeve 5 and at least one wedge 4 . see Figure 3 to Figure 5 , the constraining sleeve 5 is provided with a variable diameter hole, the variable diameter hole includes a circular hole 52 and a tapered hole 51, the tapered hole 51 is similar to an inverted trumpet hole, one end of which is the same and communicated with the circular hole 52 inner diameter, and the other end of the inner diameter It is larger than the inner diameter of the circular hole 52, that is, the side wall of the tapered hole 51 forms an inclined plane. The outer circumference of the constraint sleeve 5 is provided with threads.

[0059] see Figure 6 to Figure 8 , the at least one wedge 4 is located in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com