A Ni-based metal catalyst and method for preparing special diamond for IC chip polishing pad dressing by utilizing the catalyst

A base metal and diamond technology, which is applied in the field of artificial crystal synthesis, can solve problems affecting processing accuracy and service life, low trimming cleanliness, and affecting polishing effects, etc., to achieve rapid development, improve processing quality, and easy temperature control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation method of Ni-based metal catalyst of the present invention:

[0048] a, expressed in weight percent, the alloy composition of the Ni-based metal catalyst consists of Co 5%, Fe 10%, Al 0.1%, La 0.5%, Cu 0.5%, B 4 C 0.005%, the balance is nickel;

[0049] b. Put the material prepared in step a into an intermediate frequency furnace, and smelt it under the protection of argon. The smelting temperature is 1550° C., and the smelting time is 20 minutes. After smelting, an alloy liquid is obtained;

[0050] c, using 5.0MPa high-pressure gas to atomize the alloy liquid obtained by smelting in step b into powder to obtain catalyst powder;

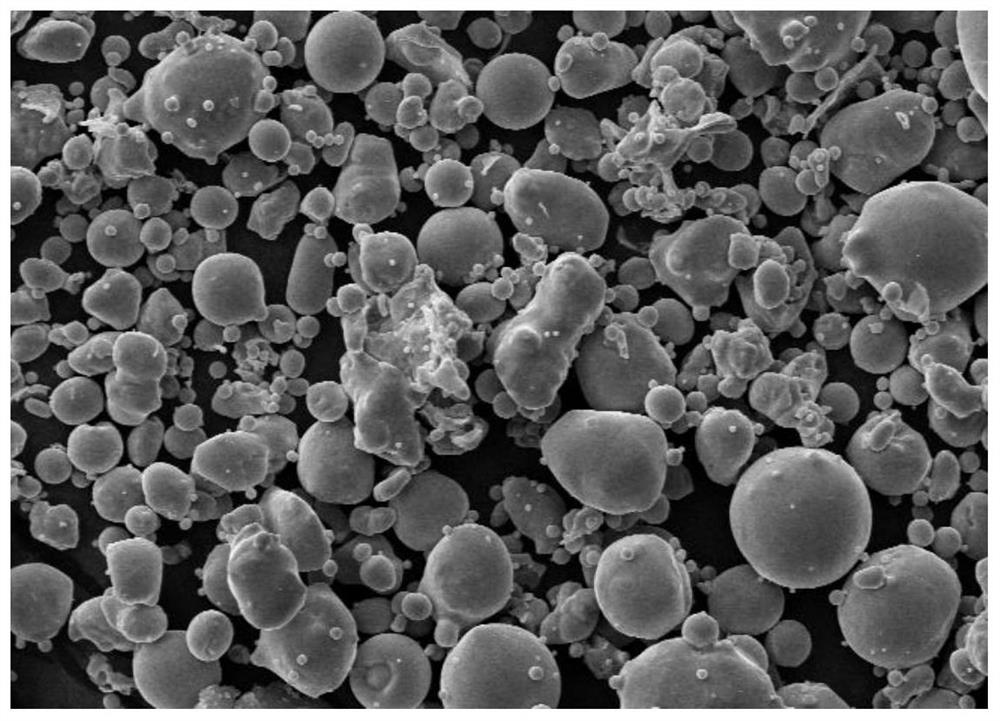

[0051] d. Sieve the catalyst powder obtained in step c, select a powdered alloy with a particle size of 5-15 μm, and obtain a Ni-based metal catalyst for synthesizing special diamond. The electron microscope picture of gained Ni-based metal catalyst is shown in the attached figure 1 .

Embodiment 2

[0053] Utilize the Ni-based metal catalyst gained in embodiment 1 to prepare the method for special diamond for IC chip polishing pad finishing, detailed steps are as follows:

[0054] (1) Preparation of synthetic column:

[0055] Take the Ni-based metal catalyst with a particle size of 5-15 μm obtained in Example 1 and the natural graphite (impurity content-3 High vacuum reduction under the condition of Pa for 12 hours, after the reduction is completed, the temperature is naturally cooled to room temperature, and then vacuum packaged for later use;

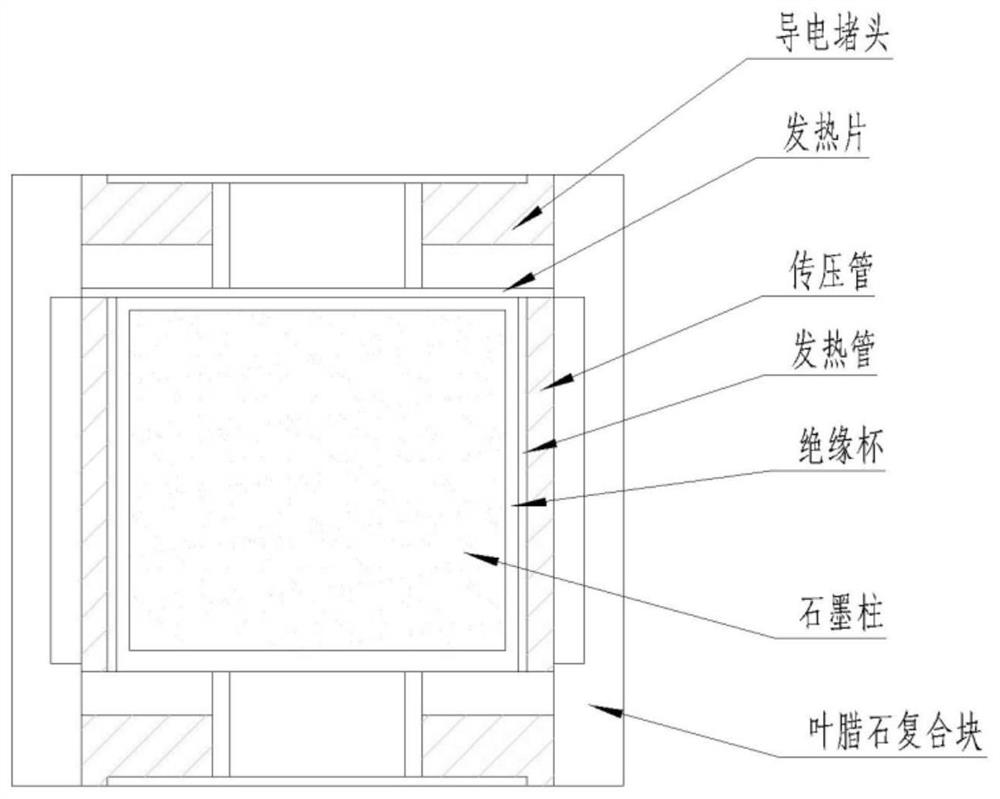

[0056] (2) Assembly of synthetic blocks:

[0057] The periphery of the synthetic column obtained in step (1) is provided with zirconia insulating cups, heating carbon tubes, sodium chloride pressure transmission tubes and composite pyrophyllite blocks sequentially from the inside to the outside according to the structure of conventional synthetic blocks, and the upper and lower ends are symmetrically arranged with heating sheets ...

Embodiment 3

[0065] The preparation method of Ni-based metal catalyst of the present invention:

[0066] a. Expressed in weight percent, the alloy formulation of the Ni-based metal catalyst consists of Co 10%, Fe 15%, Al 0.5%, La 1.0%, Cu 1.0%, B 4 C 0.01%, the balance is nickel.

[0067] b. Put the material prepared in step a into the intermediate frequency furnace, and melt it under the protection of argon. The melting temperature is 1580 ° C, and the melting time is 18 minutes. After melting, the alloy liquid is obtained;

[0068] c, using 6.0MPa high-pressure gas to atomize the alloy liquid obtained by smelting in step b into powder to obtain catalyst powder;

[0069] d. Sieve the catalyst powder obtained in step c, select a powdered alloy with a particle size of 5-20 μm, and obtain a Ni-based metal catalyst for synthesizing special diamond.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com