Submarine cable connection operation device and operation method thereof

A submarine cable and operating device technology, applied in the direction of cable laying ships, etc., can solve the problems of submarine cable failure, easy damage, frequent damage accidents, etc., achieve safe and reliable recovery, reduce power loss, and reduce frictional resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

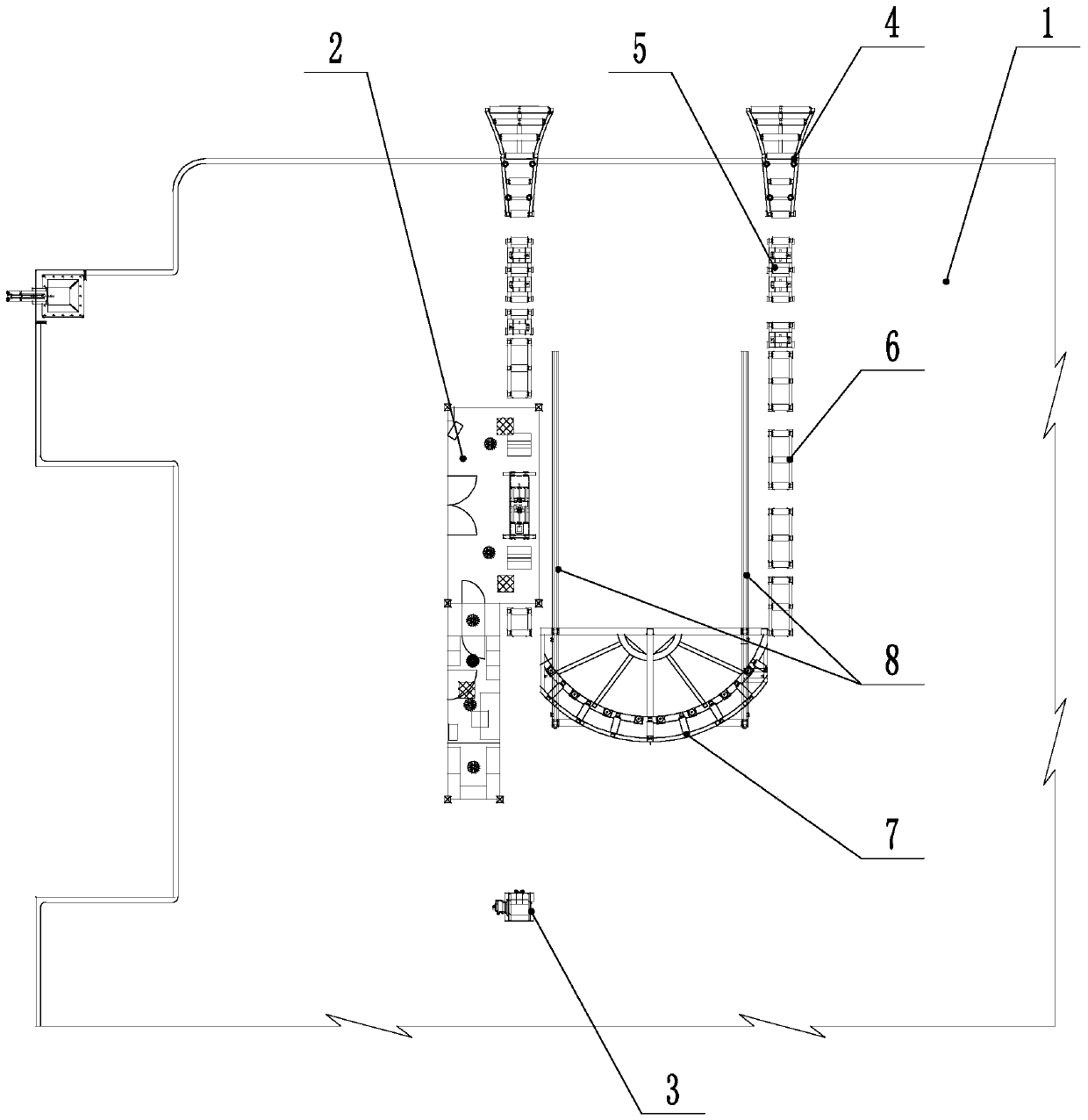

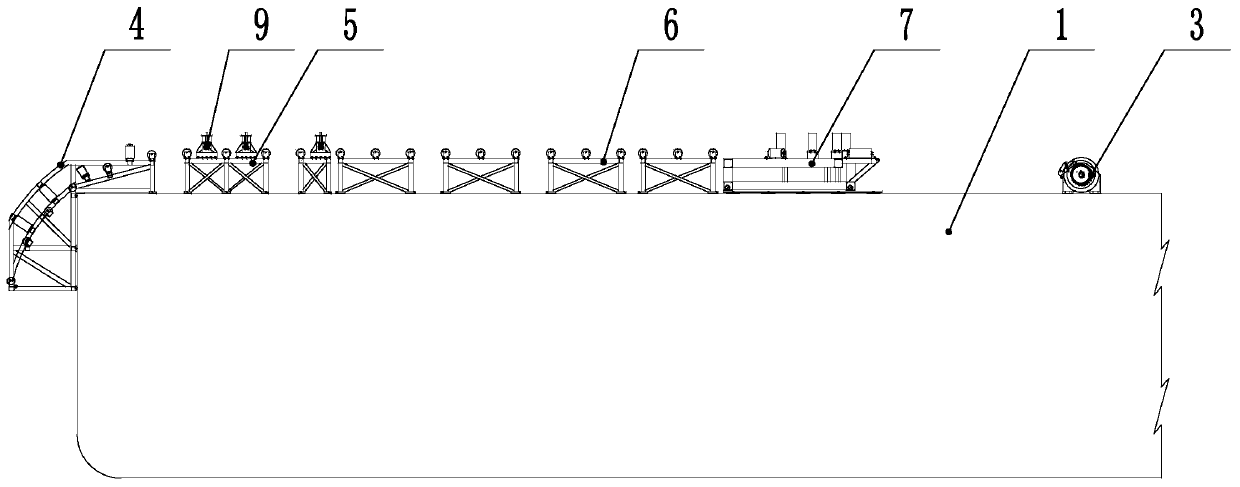

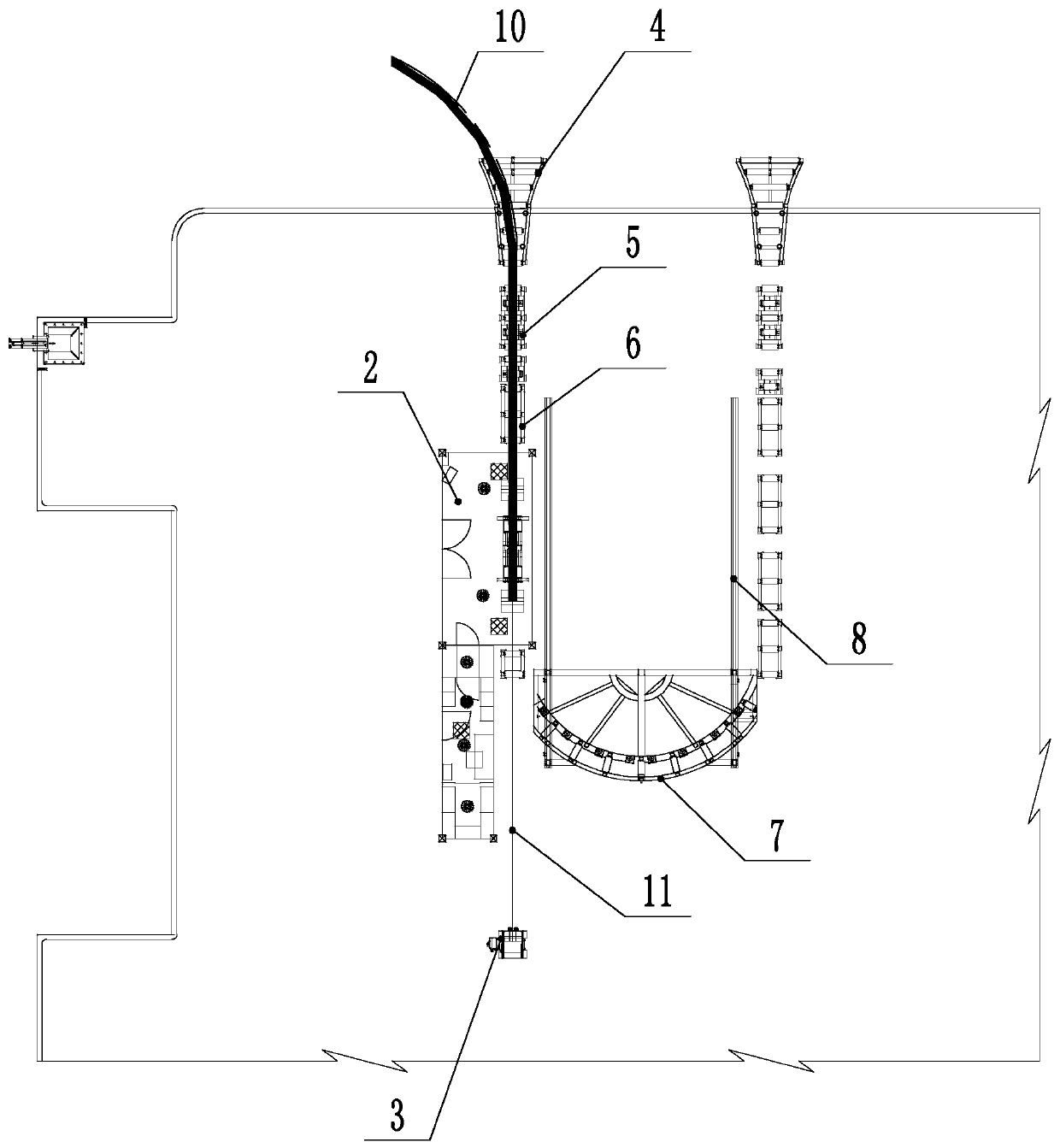

[0033] like Figure 1-2 As shown, a submarine cable connection operation device includes a cable 10 guiding device fixedly connected to the hull 1, a connecting room 2 and a cable traction winch 3, and the cable 10 guiding device includes two sets of water outlet guide rollers 4 and locking guide rollers. Group 5, horizontal guide roller group 6, U-shaped guide roller group 7 and guide rail 8, the protruding outboard part of water outlet guide roller group 4 is arc-shaped in both horizontal and vertical directions, and two sets of water outlet guide roller group 4 are installed on the same side of the ship's side ; The locking guide roller set 5 is provided with a safety locking device 9 for fixing the cable 10, and the U-shaped guide roller set 7 is a large U-shaped structure; after the cable 10 is connected, the U-shaped guide roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com