A polymer material with anti-icing function and its integrated molding method

A technology of polymer materials and molding methods, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of many steps, unstable performance and high cost, and achieves simple operation, good structural formability, and microstructure distribution. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

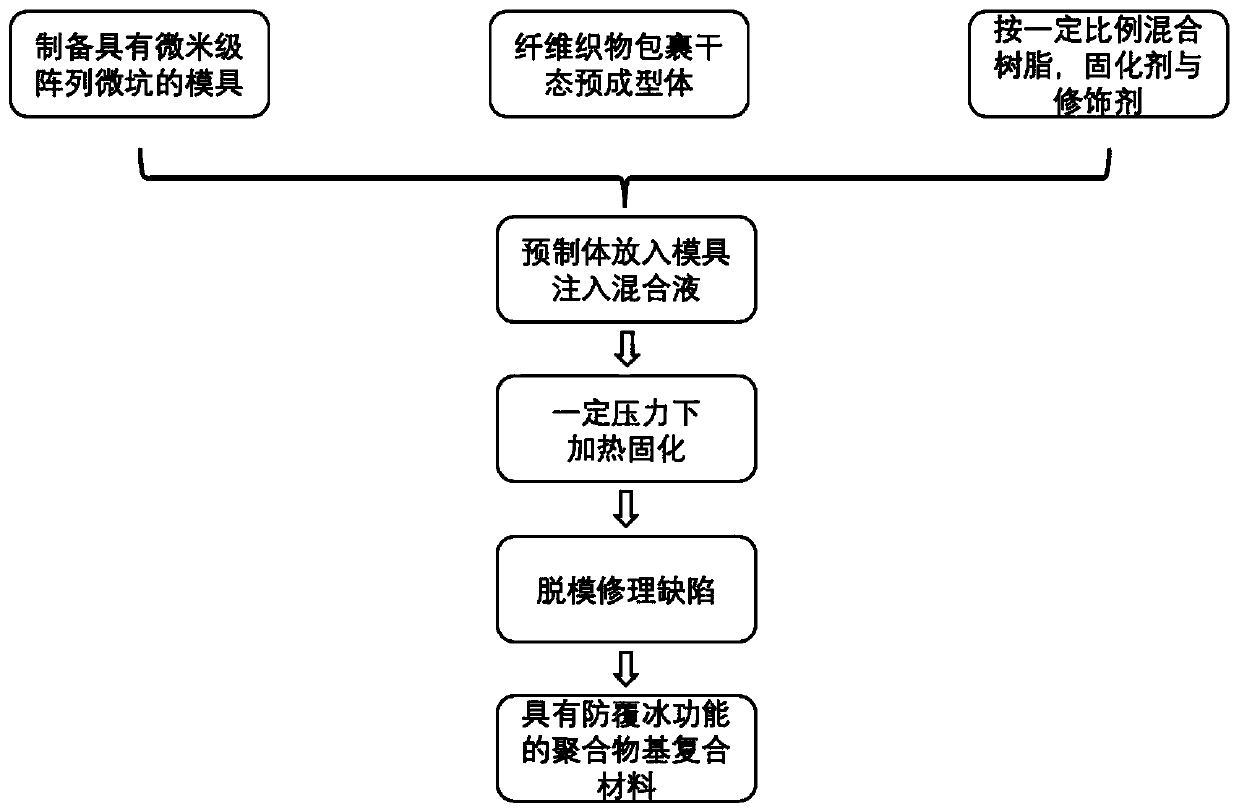

[0036] A polymer material integrated molding method with anti-icing function, comprising the following steps:

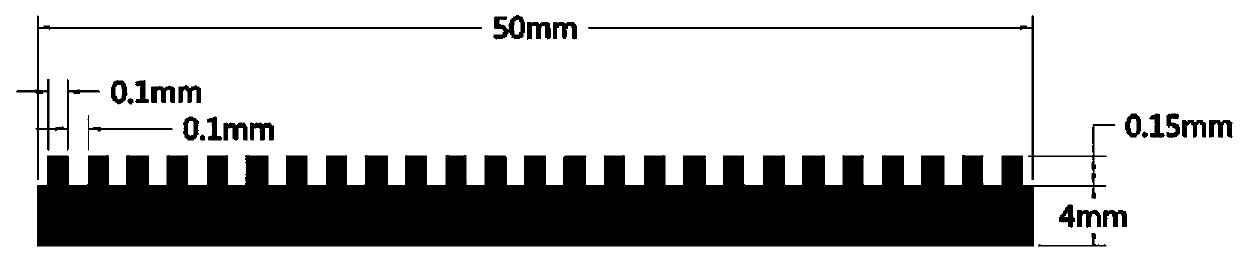

[0037] (1) A closed 7075 aluminum alloy mold with a square pit array microstructure on the inner wall is prepared by a precision numerical control lathe, cleaned for standby, and pre-coated with a release agent;

[0038] (2) Cut the fiber cloth to a suitable shape, and then wrap the PVC foam core material to obtain a dry fiber prefabricated body; the fiber cloth is made of SW220 high-strength glass fiber, and the core material is made of PVC foam, with a size of 50mmx50mmx4mm;

[0039] (3) Mix resin, curing agent and low surface energy modifier heptadecafluorodecyltriethoxysilane FAS-17 at a mass ratio of 3:1:0.01 to obtain a liquid polymer mixture;

[0040] (4) Place the dry fiber prefabricated body in the closed metal mold; inject the liquid polymer mixture into the dry fiber prefabricated body after closing the mold, until the liquid colloid without bubbles flows ...

Embodiment 2

[0045] A polymer material integrated molding method with anti-icing function, comprising the following steps:

[0046] (1) A closed 7075 aluminum alloy mold with an inverted pyramid pit array microstructure on the inner wall is prepared on a precision numerical control lathe, cleaned for standby, and pre-coated with a release agent;

[0047] (2) Cut the fiber cloth to a suitable shape, and then wrap the PVC foam core material to obtain a dry fiber prefabricated body; the fiber cloth is made of T700SC-12000-50C high-strength carbon fiber material, and the high-strength carbon fiber material is pre-coated with epoxy resin slurry ;The core material is PVC foam, the size is 50mmx 50mmx4mm;

[0048] (3) Mix resin, curing agent and low surface energy modifier heptadecafluorodecyltriethoxysilane FAS-17 at a mass ratio of 3:1:0.01 to obtain a liquid polymer mixture;

[0049] (4) Place the dry fiber prefabricated body in the closed metal mold; inject the liquid polymer mixture into th...

Embodiment 3

[0054] A polymer material integrated molding method with anti-icing function, comprising the following steps:

[0055] (1) A closed 7075 aluminum alloy mold with a square pit array microstructure on the inner wall is prepared by a precision numerical control lathe, cleaned for standby, and pre-coated with a release agent;

[0056] (2) Cut the fiber cloth to a suitable shape, and then wrap the PVC foam core material to obtain a dry fiber prefabricated body; the fiber cloth is made of aramid fiber, and the core material is made of PVC foam, with a size of 50mmx 50mmx4mm;

[0057] (3) Mix resin, curing agent and low surface energy modifier heptadecafluorodecyltriethoxysilane FAS-17 at a mass ratio of 3:1:0.01 to obtain a liquid polymer mixture;

[0058] (4) Place the dry fiber prefabricated body in the closed metal mold; inject the liquid polymer mixture into the dry fiber prefabricated body after closing the mold, until the liquid colloid without bubbles flows out of the glue ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com