A guide rail installation and adjustment device and installation method for flat knitting machines

The technology of a flat knitting machine and an assembly and adjustment method, which is applied in the field of knitting machinery, can solve the problems of high difficulty, complex assembly and adjustment procedures, low efficiency, etc., and achieves the effects of good installation requirements, satisfying installation requirements, and simple assembly and adjustment methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

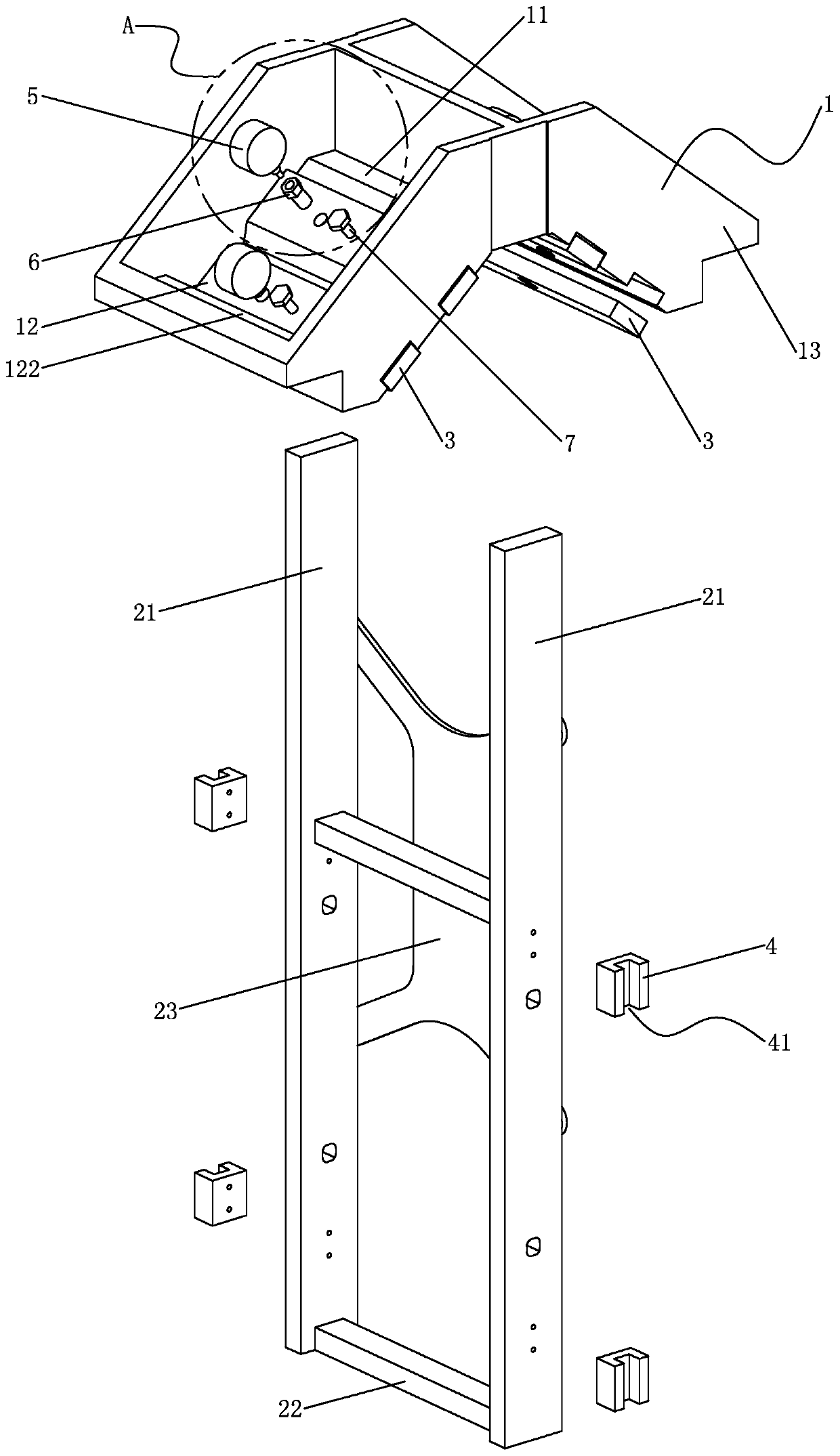

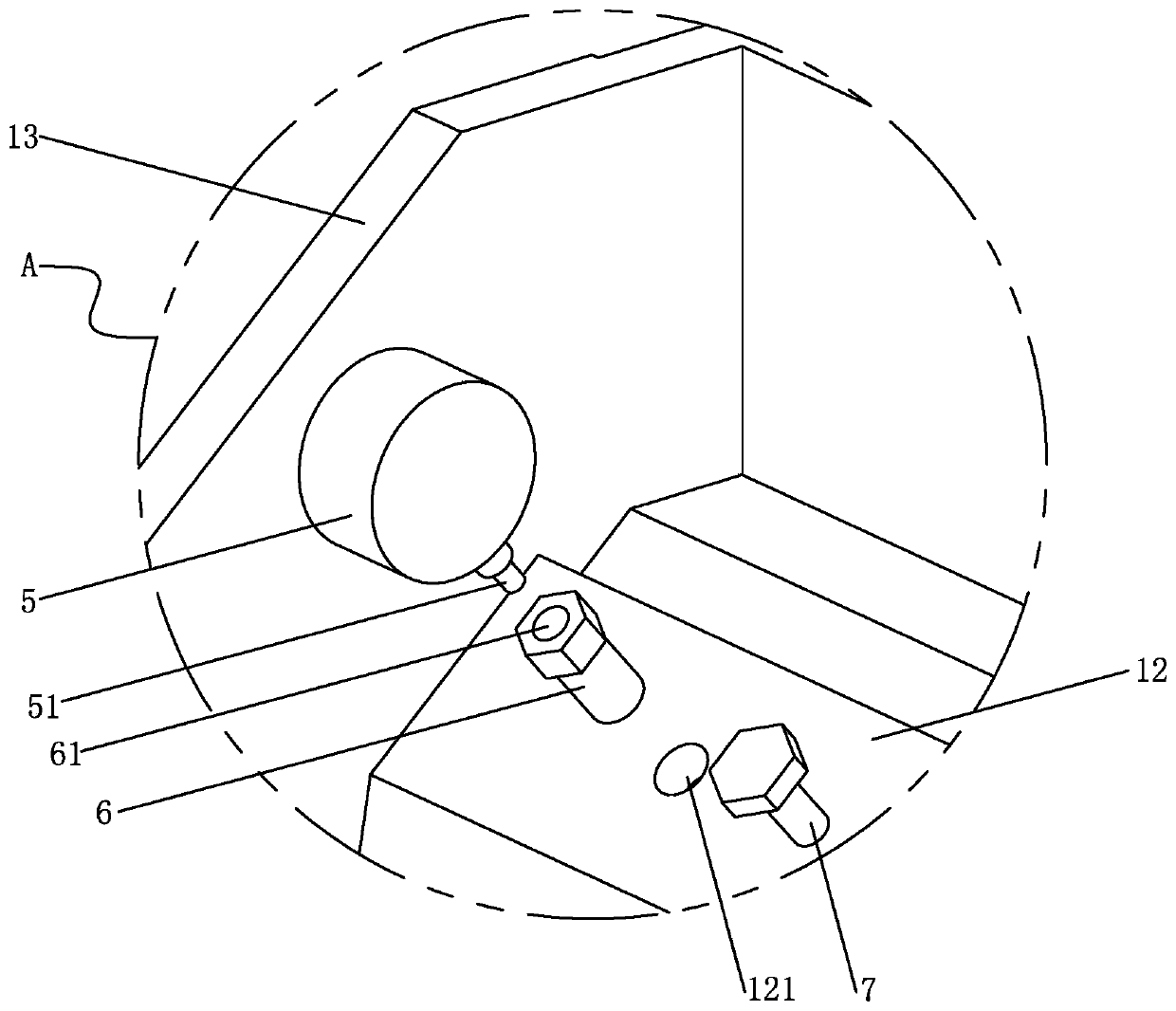

[0040] like figure 1 , figure 2 , image 3As shown, a guide rail installation and adjustment device 100 for a flat knitting machine provided by Embodiment 1 of the present invention includes a reference base 1 and a calibration frame 2. The reference base 1 includes a seat plate 11 and a base plate 12 connected to the seat plate 11. The base plate 12 is provided with two pieces and is respectively connected to the opposite sides of the seat plate 11. The two base plates 12 are arranged obliquely and symmetrically. 12 are equipped with detection pieces corresponding to the reference block 3, the calibration frame 2 is connected to the reference base 1 and is perpendicular to the seat plate 11, and the calibration frame 2 is provided with a positioning piece for determining the installation direction of the guide rail.

[0041] In this embodiment, the detection part adopts the dial gauge 5. In order to ensure the installation accuracy of the guide rail 410, two reference bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com