Joint and support pin assembly

A technology of supporting pins and assemblies, applied in interconnection systems, springs and suspensions made of plastic materials, etc., can solve the problems of limited service life, loss of pressure of the elastic body, easy detachment, etc., to achieve extended service life, convenient replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

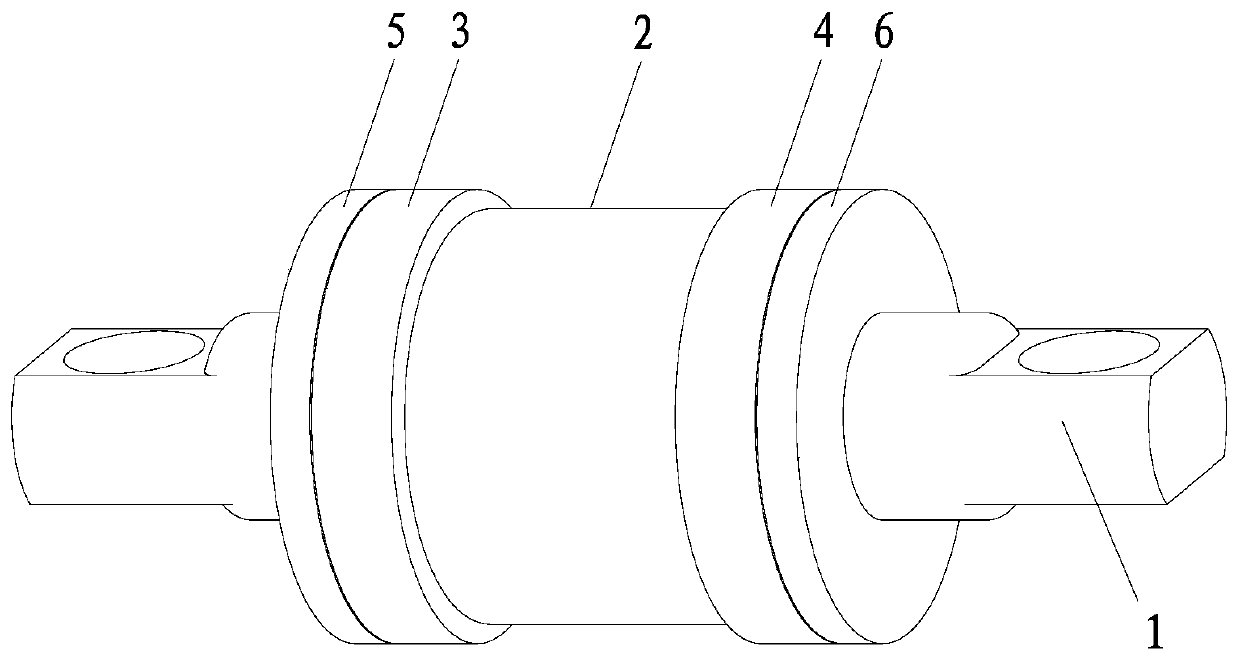

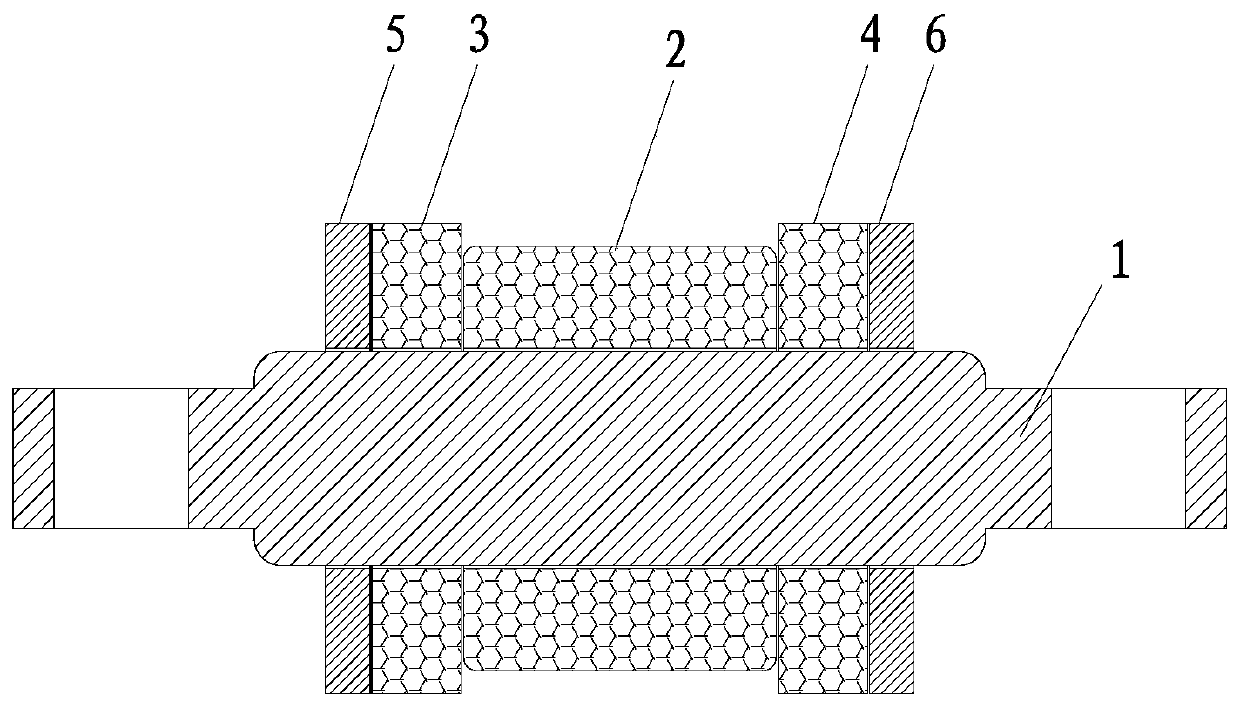

[0039] Joint and supporting pin assembly of the present invention, embodiment is as figure 1 and 2 As shown, it includes a support pin 1, an inner elastic body 2, a first outer elastic body 3, a second outer elastic body 4, a first rigid fixed baffle 5 and a second rigid fixed baffle 6; the inner elastic body 2 is tight It is wrapped on the cylindrical surface of the support pin 1 and is arranged corresponding to the axial middle section of the support pin 1; the first outer elastic body 3 and the second outer elastic body 4 are sleeved on the support pin On the bearing pin 1, and the axial inner end surfaces of the first outer elastic body 3 and the second outer elastic body 4 are respectively stacked on the axial end surfaces of the inner elastic body 2, the first outer elastic body The maximum radial dimension of the body 3 and the second outer elastic body 4 is larger than the maximum radial dimension of the inner elastic body 2; the first rigid fixed baffle 5 and the sec...

Embodiment 2

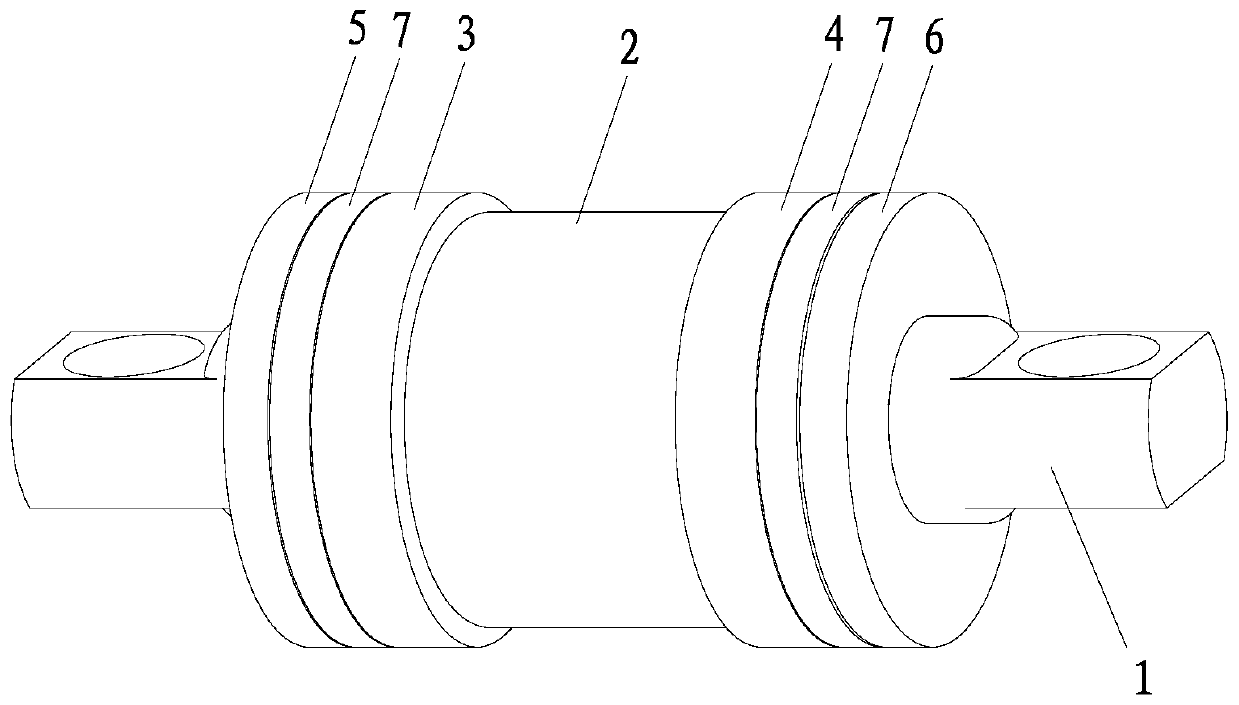

[0053] Joint and supporting pin assembly of the present invention, embodiment two such as image 3 and 4 As shown, the difference between this embodiment and Embodiment 1 is that it also includes a rigid movable washer 7, which is sleeved on the support pin 1 and placed on the first outer elastic body 3 and the second elastic body respectively. Between a rigid fixed baffle 5 and between the second outer elastic body 4 and the second rigid fixed baffle 6 . When the first rigid fixed baffle 5 or / and the second rigid fixed baffle 6 are installed on the support pin 1 in a detachable manner, especially when the first rigid fixed baffle 5 or / and the second rigid fixed baffle When the plate 6 is installed on the support pin by threaded connection, the rigid movable gasket 7 can effectively prevent the first rigid fixed baffle 5 or / and the second rigid fixed baffle 6 from rotating and loosening during work, thereby ensuring that the entire joint and The working reliability of the su...

Embodiment 3

[0056] Joint and supporting pin assembly of the present invention, embodiment three such as Figure 5 and 6 As shown, the difference between this embodiment and Embodiment 1 is that it also includes a rigid movable baffle 8, which is movably fitted on the supporting pin 1 and sandwiched between the first outer elastic body respectively. 3 and the inner elastic body 2 and between the second outer elastic body 4 and the inner elastic body 2; and the maximum radial dimension of the rigid movable baffle 8 is greater than that of the inner elastic body 2 Maximum radial dimension. When the joint and supporting pin assembly of the present invention are assembled on the rod head of the reaction rod, the rigid movable baffles 8 respectively abut against the axial two ends of the rod head of the reaction rod.

[0057] When working, when the inner elastic body 2 is radially squeezed, the inner elastic body 2 is extruded outward along the axial direction due to the restriction of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com