Vacuum oil filling method adopting vacuum oil filling device for petroleum drilling

An oil injection device and oil drilling technology, applied in directional drilling, fluid pressure actuation device, fluid pressure actuation system components, etc., can solve the problem that oil bubbles cannot be effectively discharged, and meet the requirements of automatic control and ensure pressure Balance and solve the effect of capsule deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

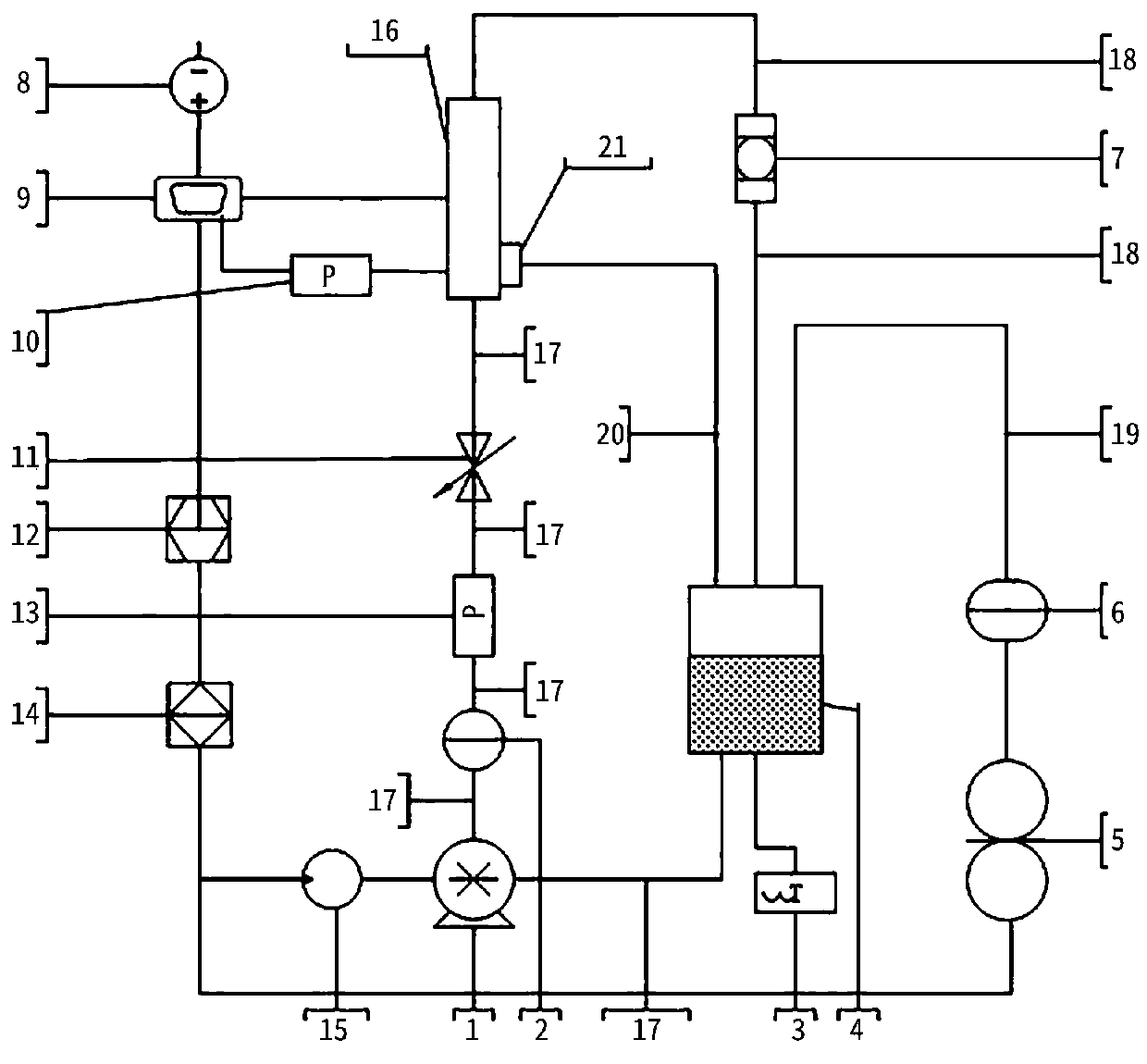

[0025] A vacuum oiling device involved in the present invention is mainly composed of a circulation system composed of an oil injection pump, an oil injection pipeline, an oil injection pressure gauge, a particle meter, a stop valve, an oil return pipeline, a filter and an oil tank, a vacuum pump, a vacuum gauge, a vacuum degree The vacuum system composed of display unit and vacuum pipeline, the balance system composed of pressure balance pipeline, vacuum joint and balance joint, the control system composed of computer, programmable logic controller and drive circuit power supply, the temperature and force display unit, the installation of circulation system, It is composed of the rack structure of vacuum system, control system and display unit.

[0026] Such as figure 1 A vacuum oiling device is shown, including: oiling motor (15), oiling pump (1), oiling pipeline (17), oiling pressure gauge (13), particle meter (2), stop valve (11), hydraulic module (16), oil return pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com