System for shell fabric printing and dyeing

A technology of fabrics and dyes, applied in the field of printing and dyeing systems, can solve the problems of reduced printing and dyeing efficiency, waste of resources, and damage to fabrics, and achieve the effects of reducing resource waste, realizing waste recycling, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

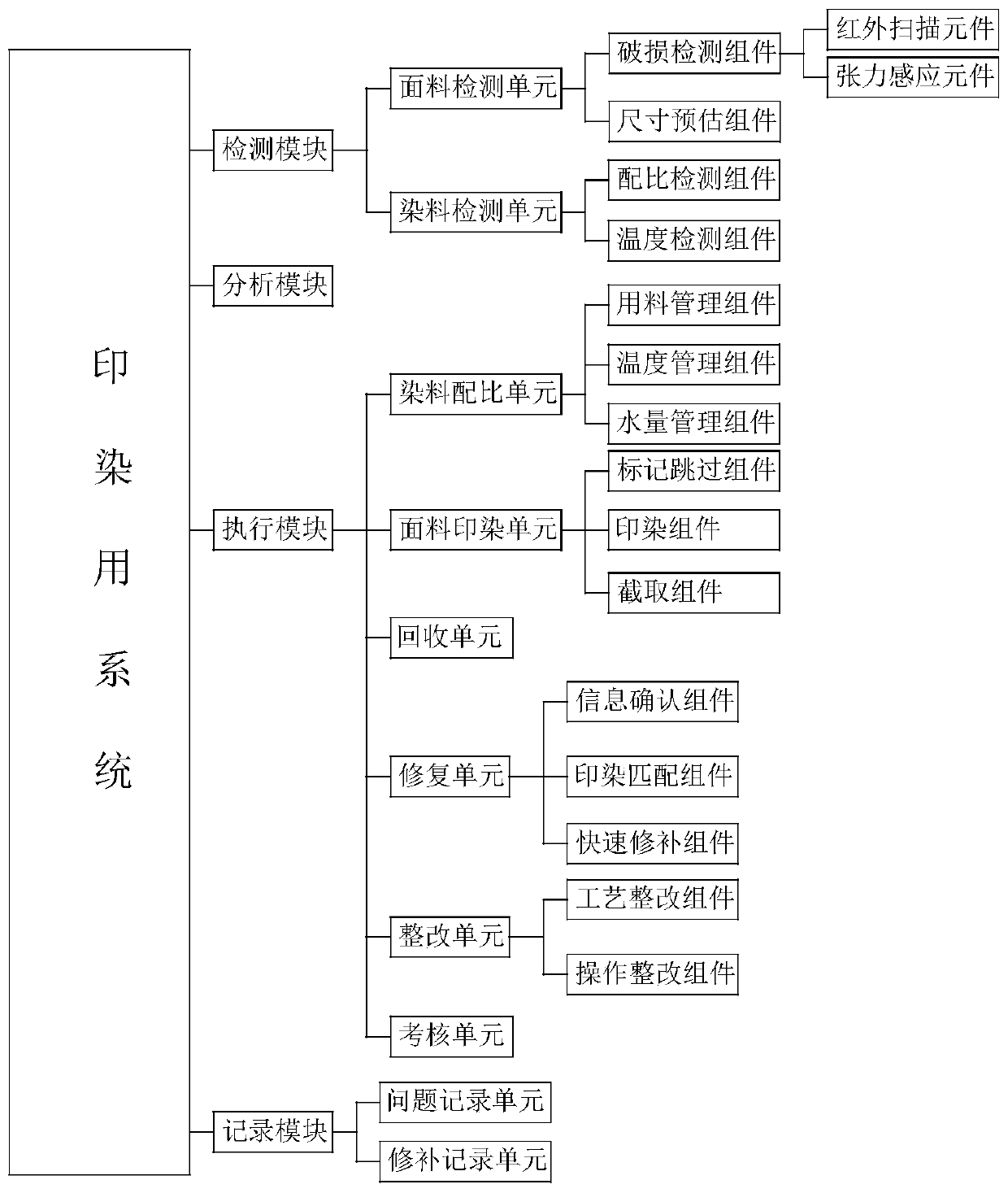

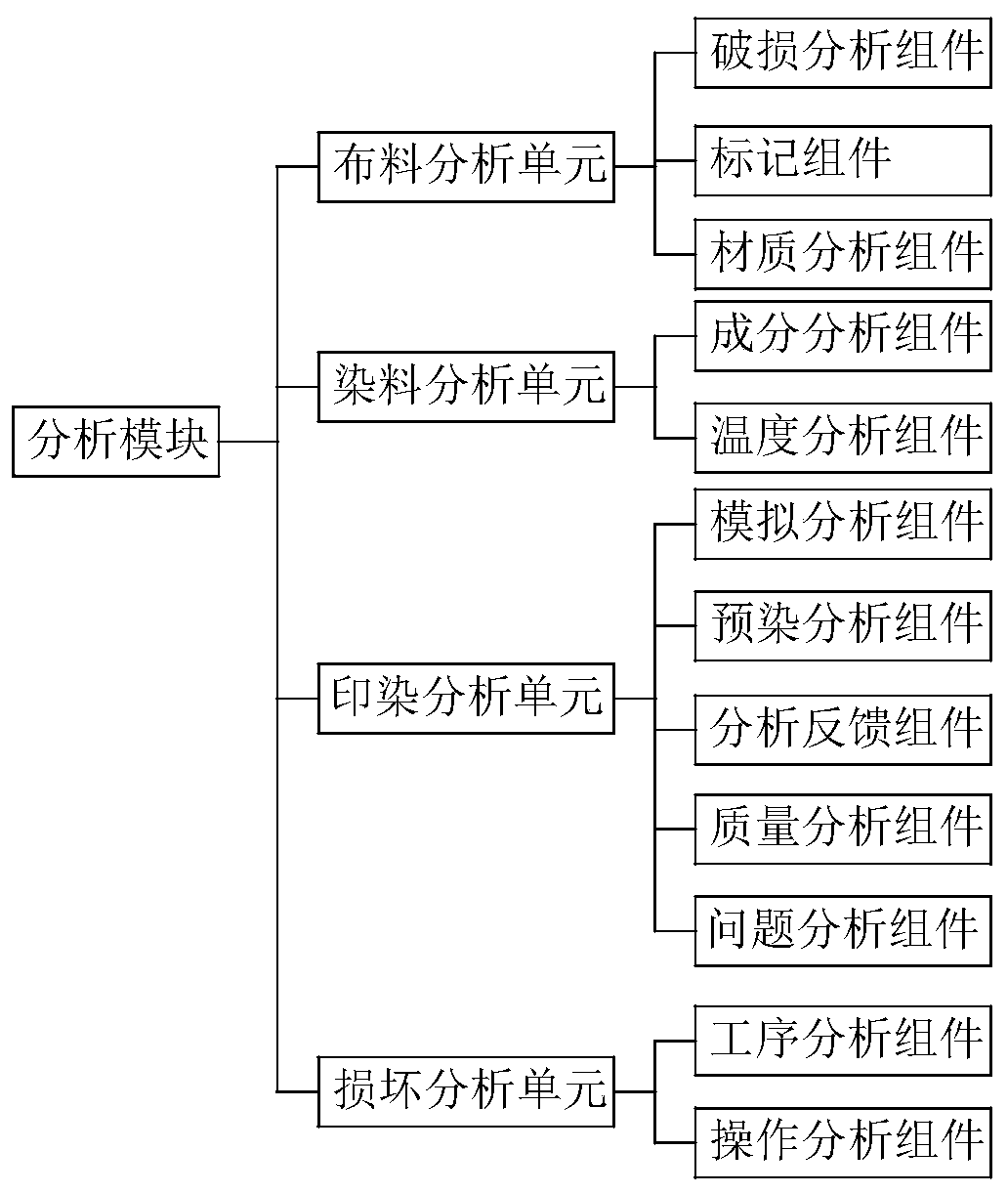

[0016] use Figure 1 to Figure 2 A fabric printing and dyeing system according to an embodiment of the present invention is described as follows.

[0017] Such as figure 1 and figure 2 As shown, a fabric printing and dyeing system includes a detection module, an analysis module, an execution module and a recording module; the detection module is used to detect various data in the printing and dyeing process, and the detection module includes a fabric detection unit; the fabric detection unit For detecting the data of the fabric, the fabric detection unit includes a damage detection component; the damage detection component is used to detect the damage of the fabric during the printing and dyeing process, and the damage detection component includes an infrared scanning element and a tension sensing element; the infrared scanning The element is used to scan the damage on the fabric, send the position information of the damage to the tension sensing element, and send the scann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com