Comprehensive ramp stopping and sliding control system applicable to electric forklift

An electric forklift, comprehensive control technology, applied in the direction of electric vehicles, control drive, electric energy management, etc., can solve the problems of difficult engineering realization, large motor current, self-heavy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

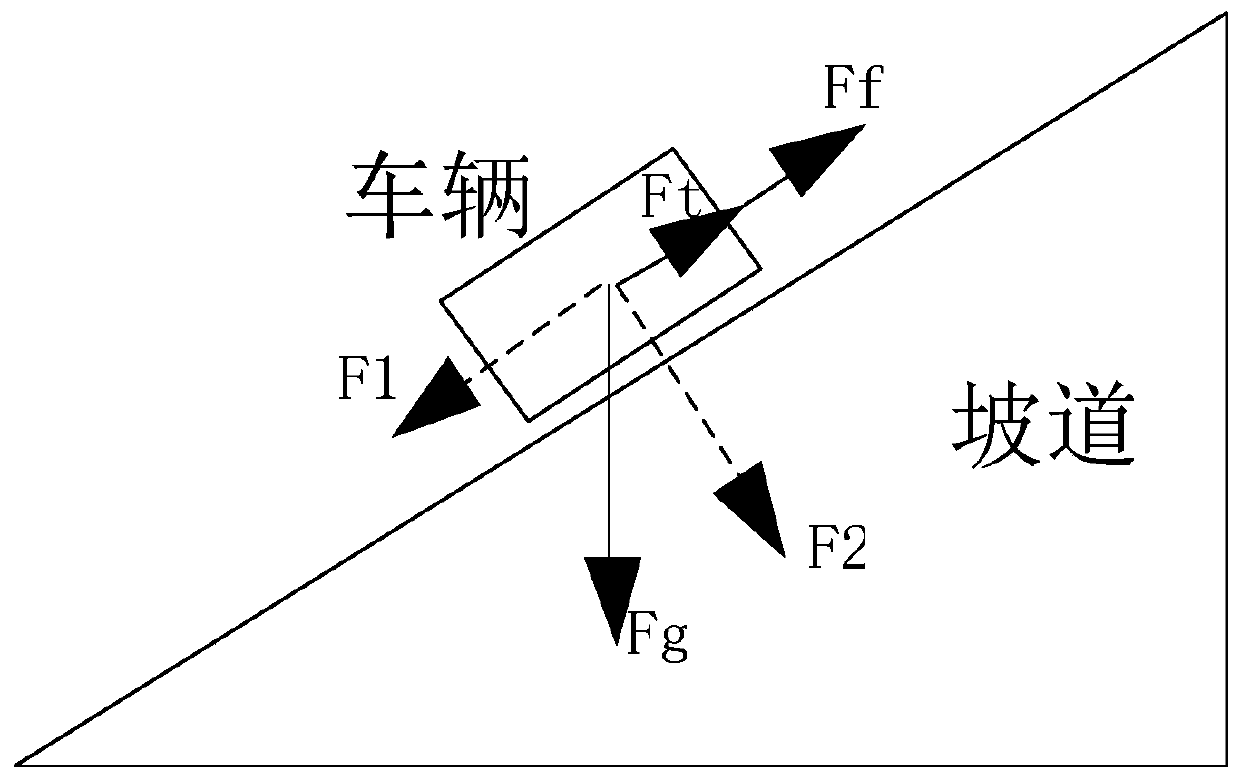

[0033] Such as image 3 As shown, the vehicle is affected by the gravity Fg on the ramp, and its force is decomposed into F1 parallel to the ramp and F2 perpendicular to the ramp, where F1 forces the vehicle to move downward, and the magnitude of F2 will affect the magnitude of the friction force Ff , where wind resistance and other effects are ignored. Due to the high gravity of the vehicle body, F1 in the system is often much larger than Ff. We know that the vehicle will slide down on the slope through the Newtonian mechanics principle. At this moment, we just need an Ft active force to overcome vehicle slide; In electric vehicle, can make the braking force of brake, also can be the electromagnetic force of motor; The electromagnetic force F=Te*R; where R is the radius of the force, e=K*Ψr*Is; where K is the parameters related to the motor body, the rotor magnetic field in the arbitrary coordinate system of Ψr, and the stator in the arbitrary coordinate system of Is The cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com