Membrane stripping mechanism capable of achieving product attaching and membrane stripping in sequence

A film peeling and sticking technology, applied in the direction of layered products, lamination auxiliary operations, lamination, etc., can solve the problems of weak strength, removal, and damage to the film material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

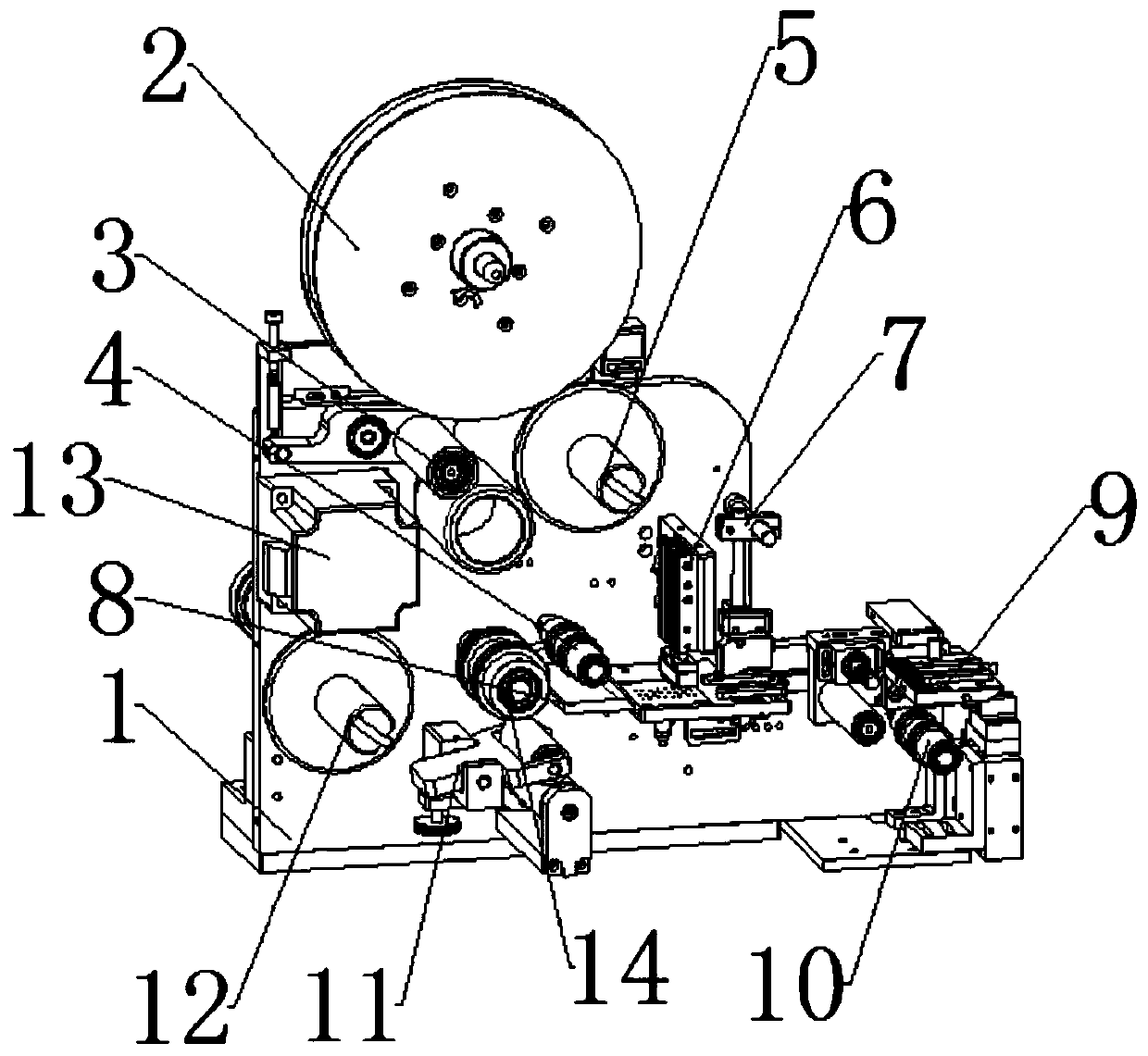

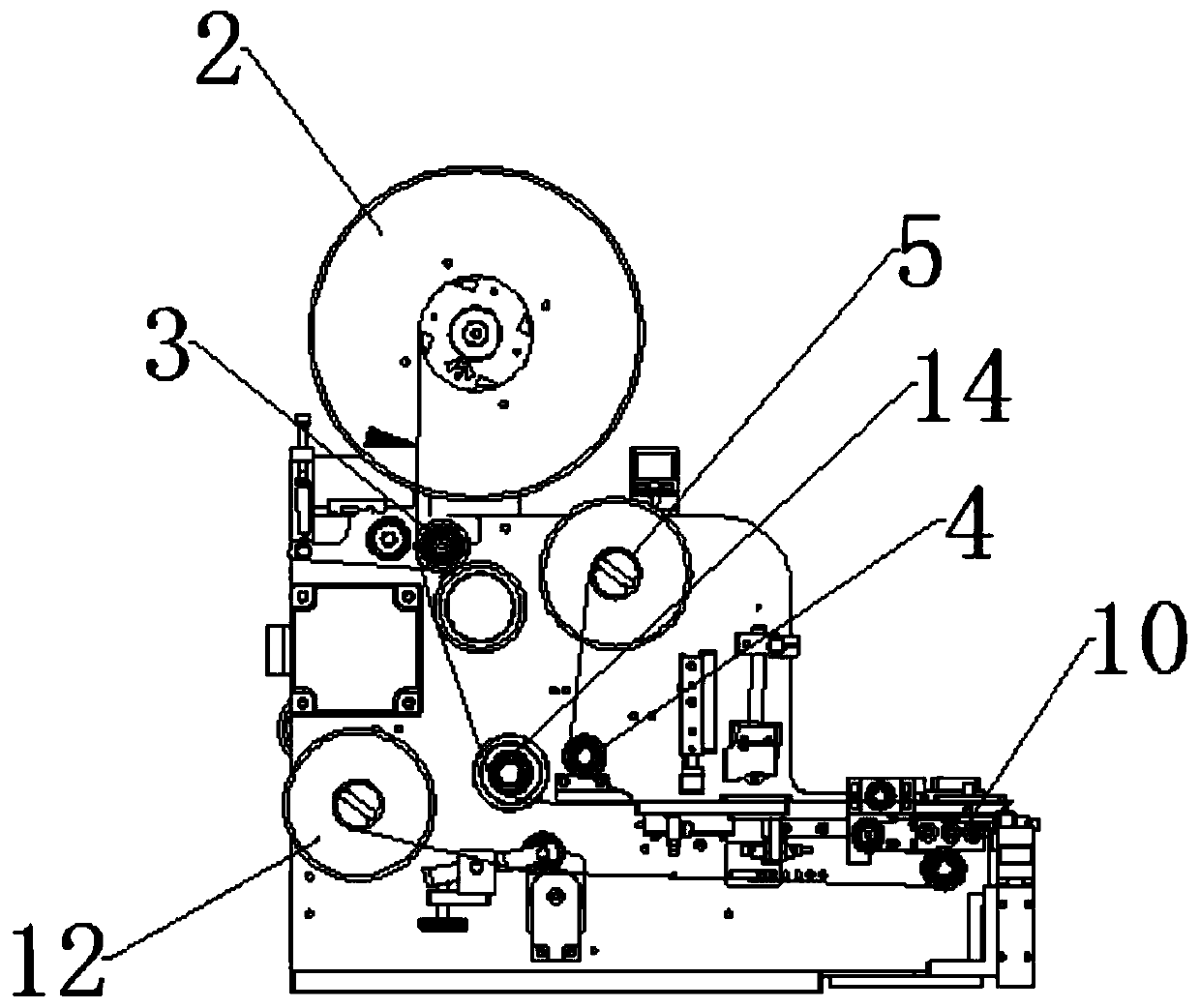

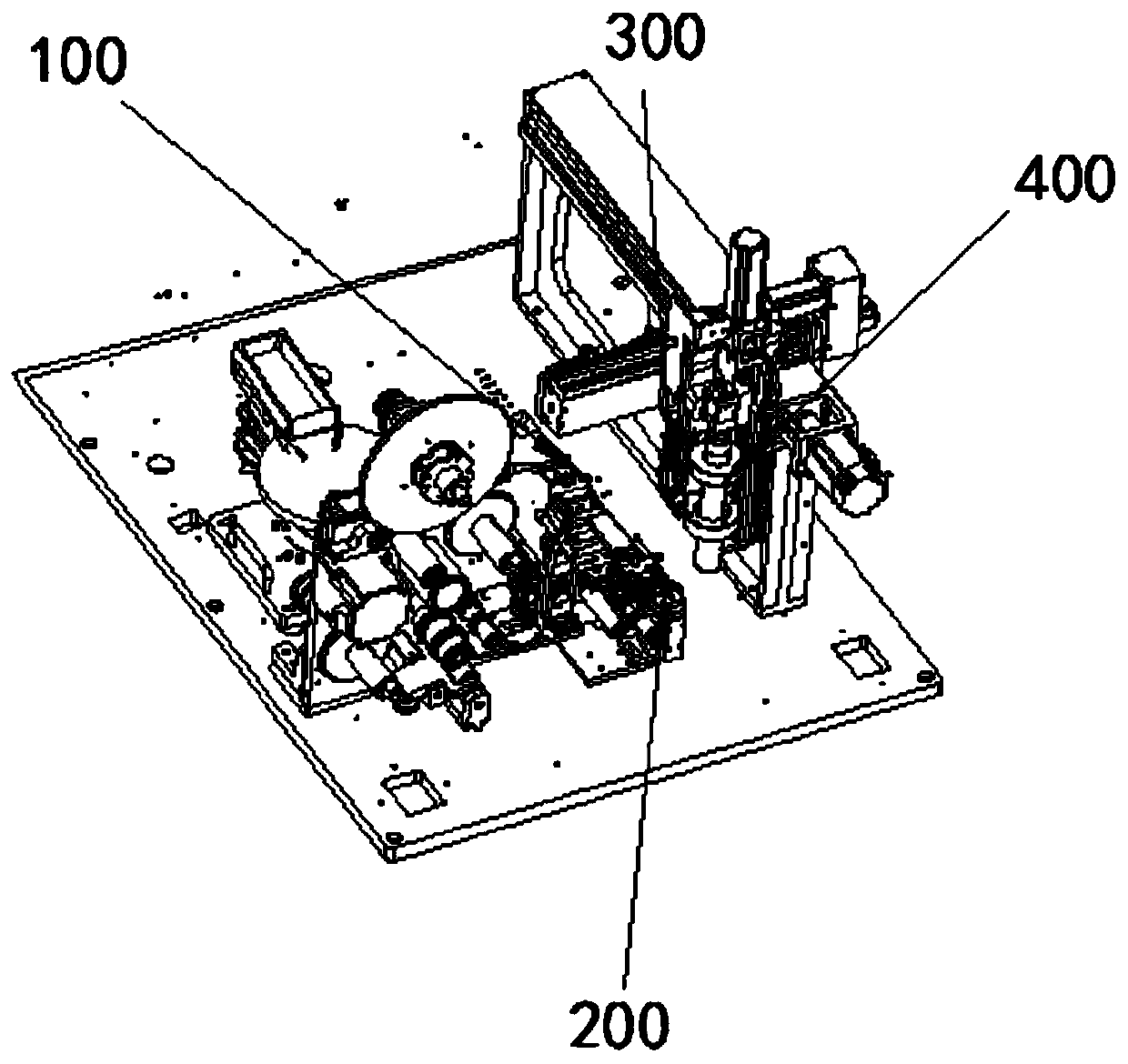

[0017] refer to Figure 1 to Figure 4 , the present invention provides a film peeling mechanism that sticks to the product first and then peels off the film, including a vertical plate 1, a film peeling motor 14, a film release wheel 2, a film material transition wheel 3, an upper film receiving assembly, and a film pressing cylinder Component 6, film material detection sensor 7, upper film stripping knife 8, lower film stripping knife 9 and lower film receiving assembly, the film release wheel 2 is installed on the top of the vertical plate 1; the film transition The wheel 3 is installed under the film release wheel 2 for adjusting the position of the film material; the upper film receiving assembly is installed under the film release wheel 2, which is located on the right side of the film material transition wheel 3, and is used to collect th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com