Passive pendulum bob type lubricating self-cleaning mechanism

A self-cleaning, hammer-type technology, applied in the direction of manipulators, manufacturing tools, joints, etc., can solve the problem of robot penetration of grease and other problems, achieve the effect of small rotation resistance, prevent oil leakage, and low temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

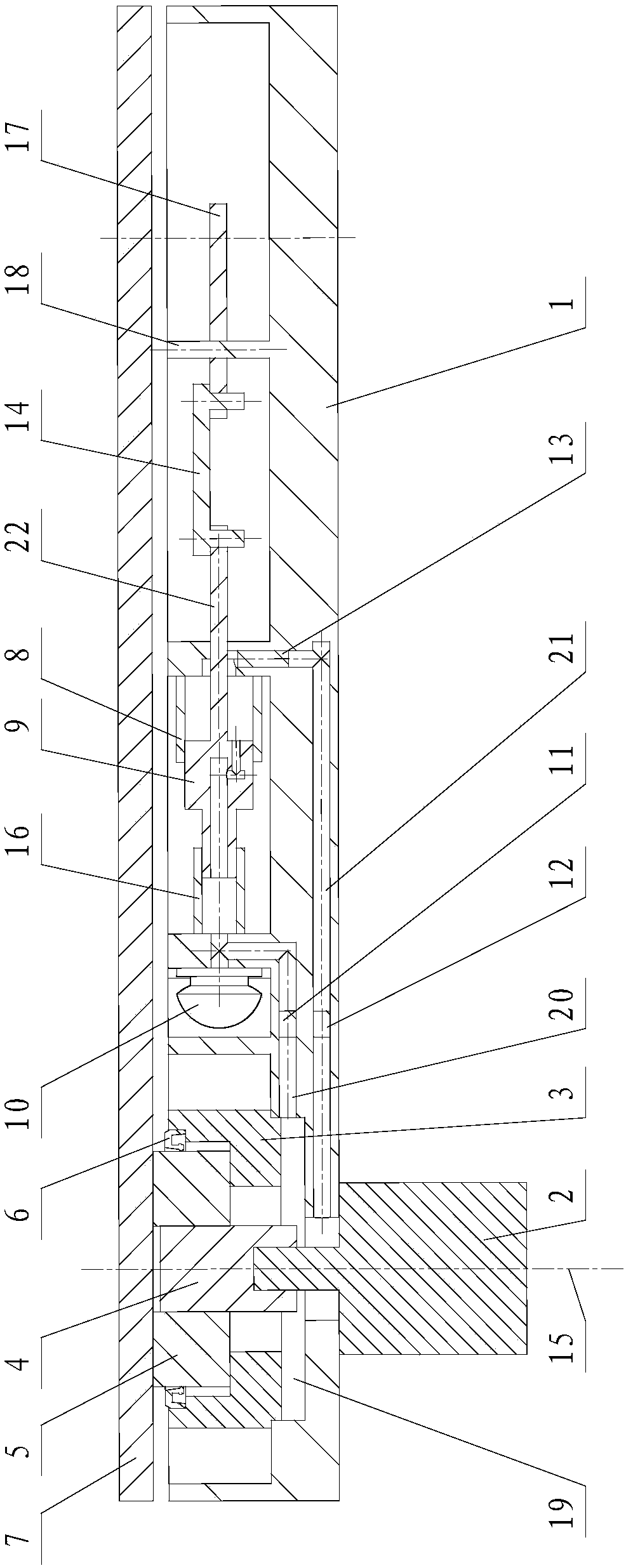

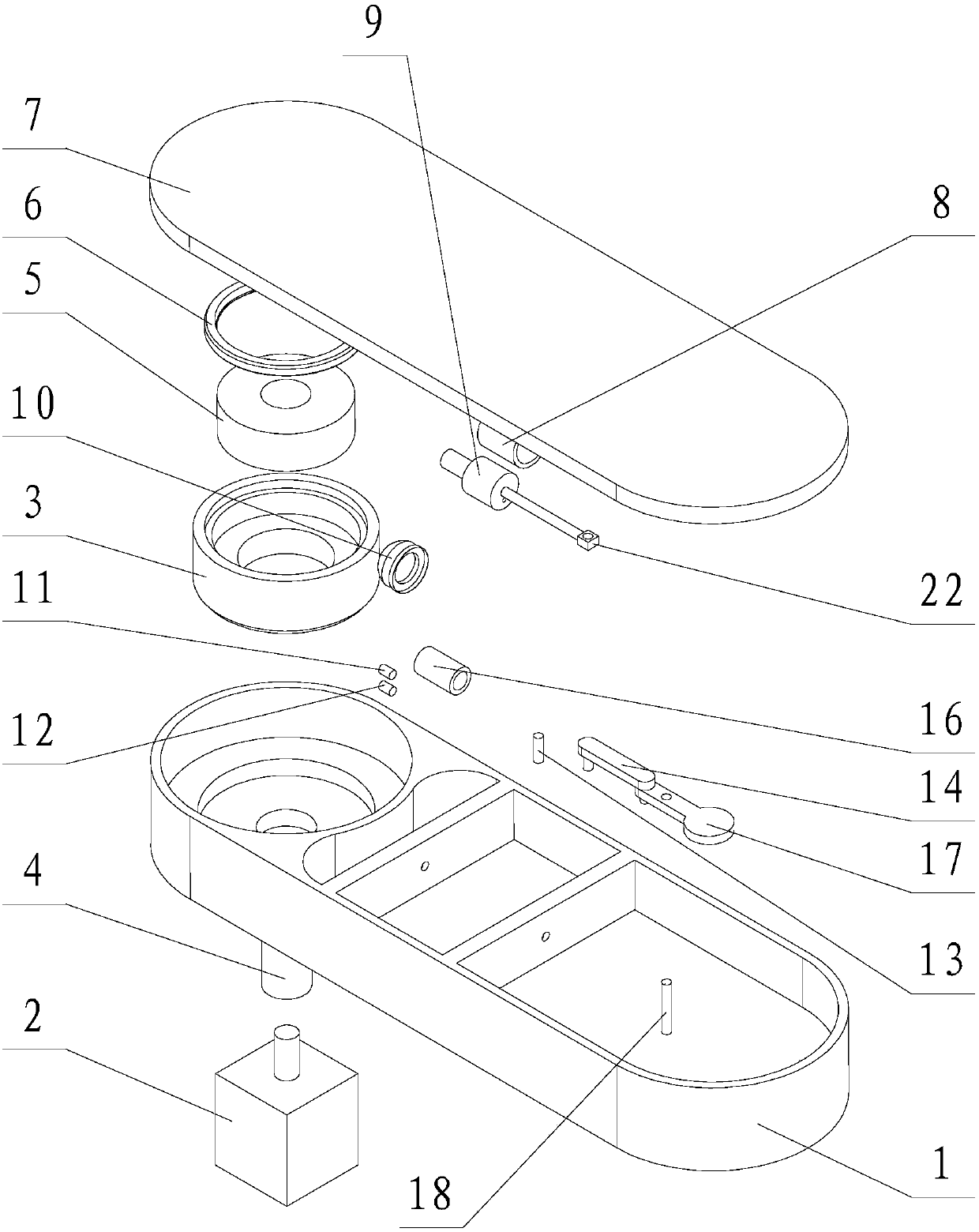

[0021] Such as figure 1 , figure 2 As shown, the present invention includes a boom 1, a small arm 7, a motor 2 and a reducer housing 3 respectively accommodated in the boom 1, a reducer input gear shaft 4, a reducer output shaft 5, a pendulum mechanism, an oil outlet One-way valve 11, oil return one-way valve 12 and filter element 13, in which the motor 2 is statically sealed and fixedly connected to the boom 1, the output end penetrates into the boom 1, through the input gear shaft 4 of the reducer and the output shaft 5 of the reducer One end of the reducer casing 3 is statically sealed and fixedly connected to the boom 1, and the other end is connected to the output shaft 5 of the reducer through a rotating dynamic seal 6. The other end of the reducer casing 3 is connected to the input shaft of the reducer. The gear shaft 4, the output shaft 5 of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com