Cooling system and vehicle drive system for drive system

A technology of cooling system and drive system, applied in cooling/ventilation device, gear lubrication/cooling, connection with control/drive circuit, etc., can solve problems such as leaks, and achieve the effect of saving components and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] specific implementation plan

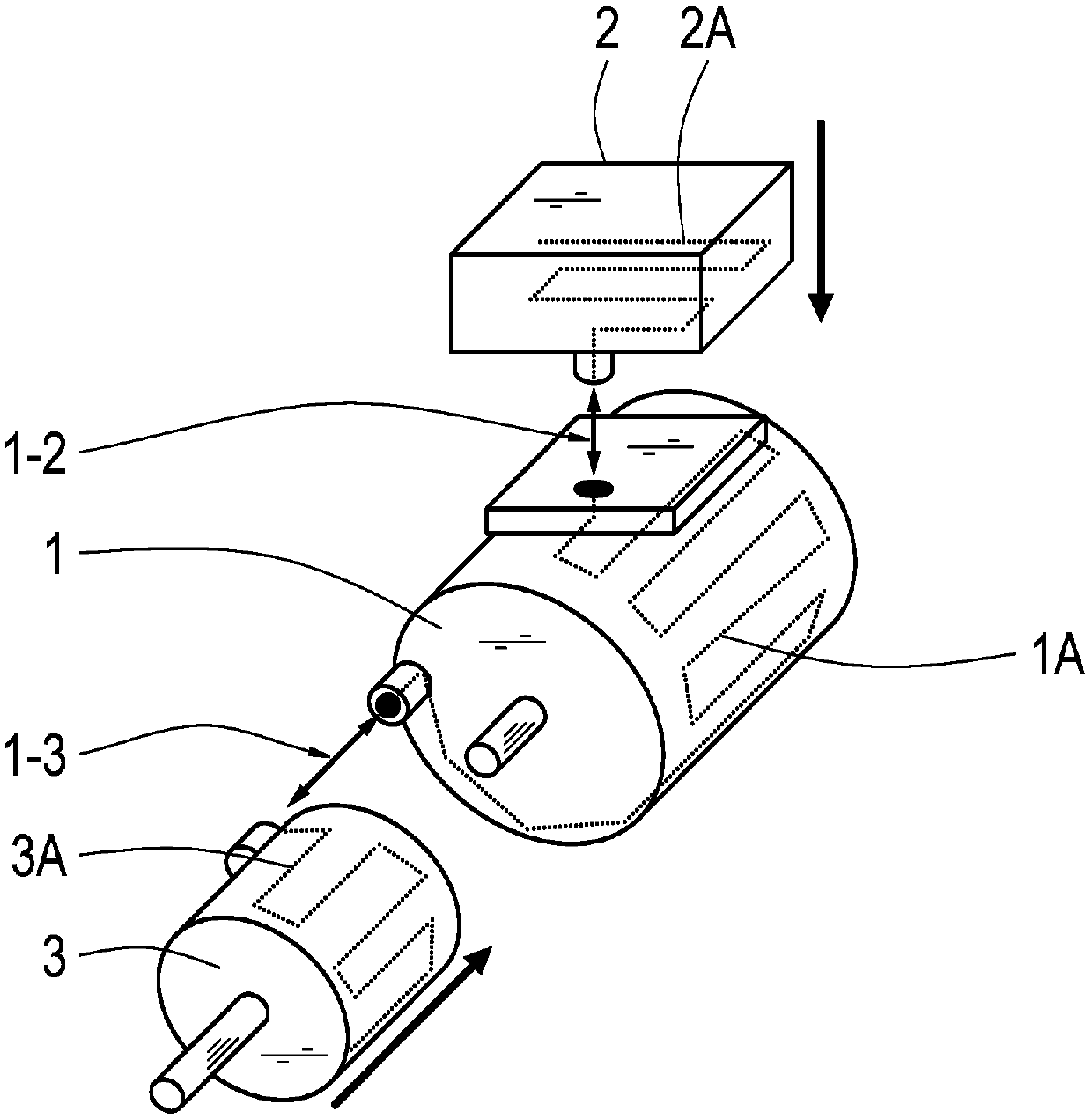

[0029] The drive system has a motor 1 and an inverter 2 for driving the motor 1 . Furthermore, the drive system has a transmission 3 for converting the torque of the electric machine 1 . The inverter 2 and the transmission 3 are designed for arrangement on an electric machine (see thick arrow). That is, the inverter 2 and the transmission 3 are fastened to the motor 1 . The transmission 3 is then fastened, for example, on the end side of the electric machine 1 and the inverter is fastened, for example, on the radial side of the electric machine 1, as figure 1 shown.

[0030] The motor 1 has a motor cooling structure 1A for guiding a cooling medium to flow through to cool the motor 1 . The inverter 2 has an inverter cooling structure 2A for guiding a cooling medium to flow through to cool the inverter 2 . Optionally, the transmission also has a transmission cooling structure 3A for guiding a cooling medium to flow through to cool the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com