High-density cross connecting cabinet

An optical cable transfer box, high-density technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of small space for optical cable transfer box, messy optical fiber routing, inconvenient management, etc., and achieve the effect of clear wiring, flexible operation and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

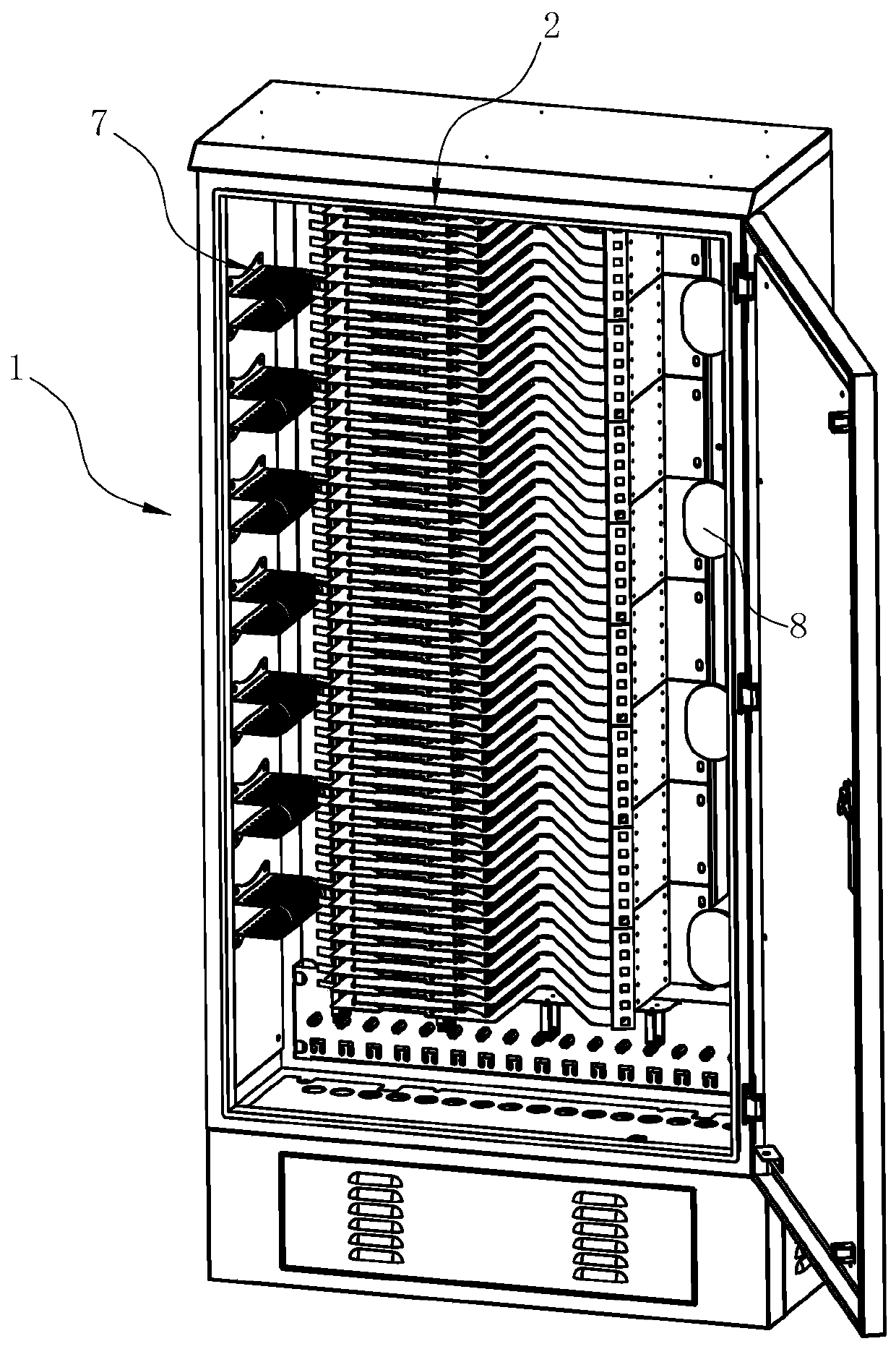

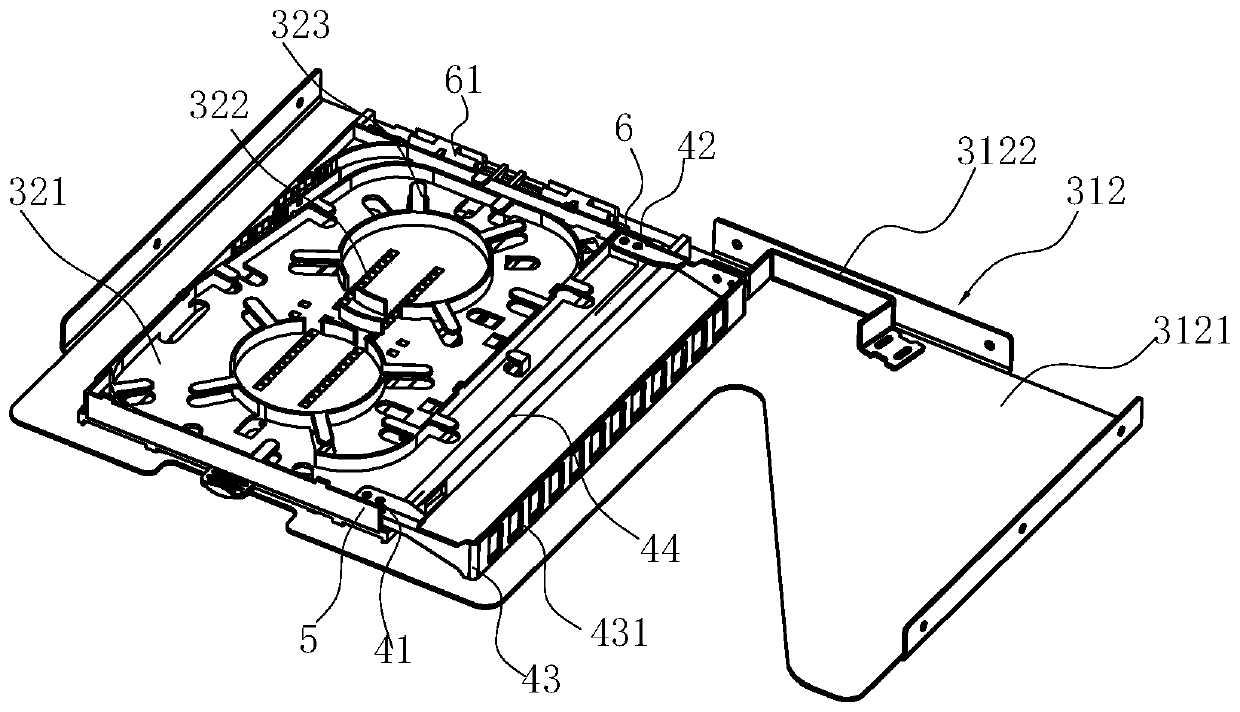

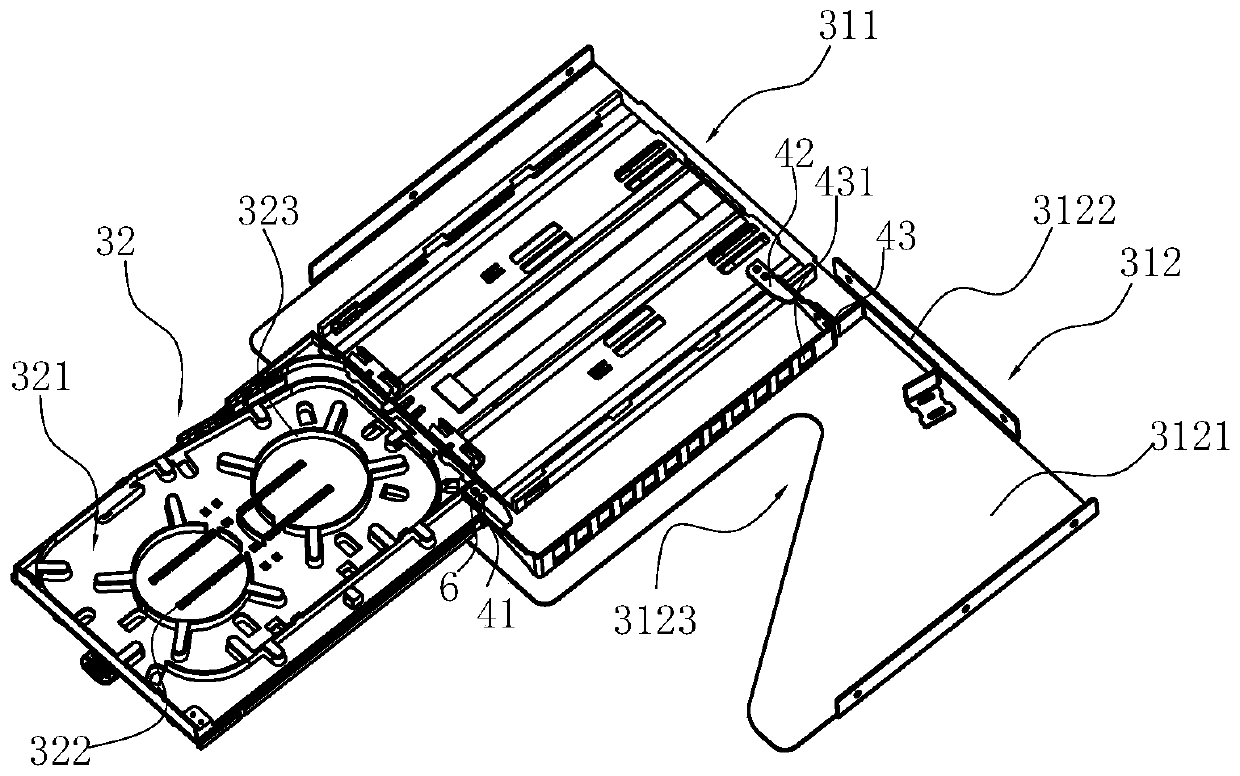

[0029] like Figure 1-9 Shown is the preferred embodiment of the present invention. The high-density fiber optic cable splicing box in this embodiment includes a frame 1, and the frame 1 includes at least two stacked optical fiber splicing tray unit boxes 2, and the optical cable splicing tray unit box 2 includes a mounting frame 21 and a And the fiber splicing tray 3 inserted on the installation frame 21 at intervals in turn, the fiber splicing tray 3 includes a tray 31 and a base 32 that can slide relative to the tray 31, wherein the base 32 includes a wall surrounded by the side wall of the base 32 And the formed concave cavity 321, the fusion splice tray 322 arranged in the central part of the cavity 321, wherein the fusion splice tray 322 includes a fusion seat with 24 cores or 36 core card slots 3221, and is arranged on the outer periph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com